Nissan Juke F15. Manual - part 455

SYSTEM

EC-633

< SYSTEM DESCRIPTION >

[MR EXCEPT FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

“Long-term fuel trim” is overall fuel compensation carried out over time to compensate for continual deviation

of the “short-term fuel trim” from the central value. Continual deviation will occur due to individual engine differ-

ences, wear over time and changes in the usage environment.

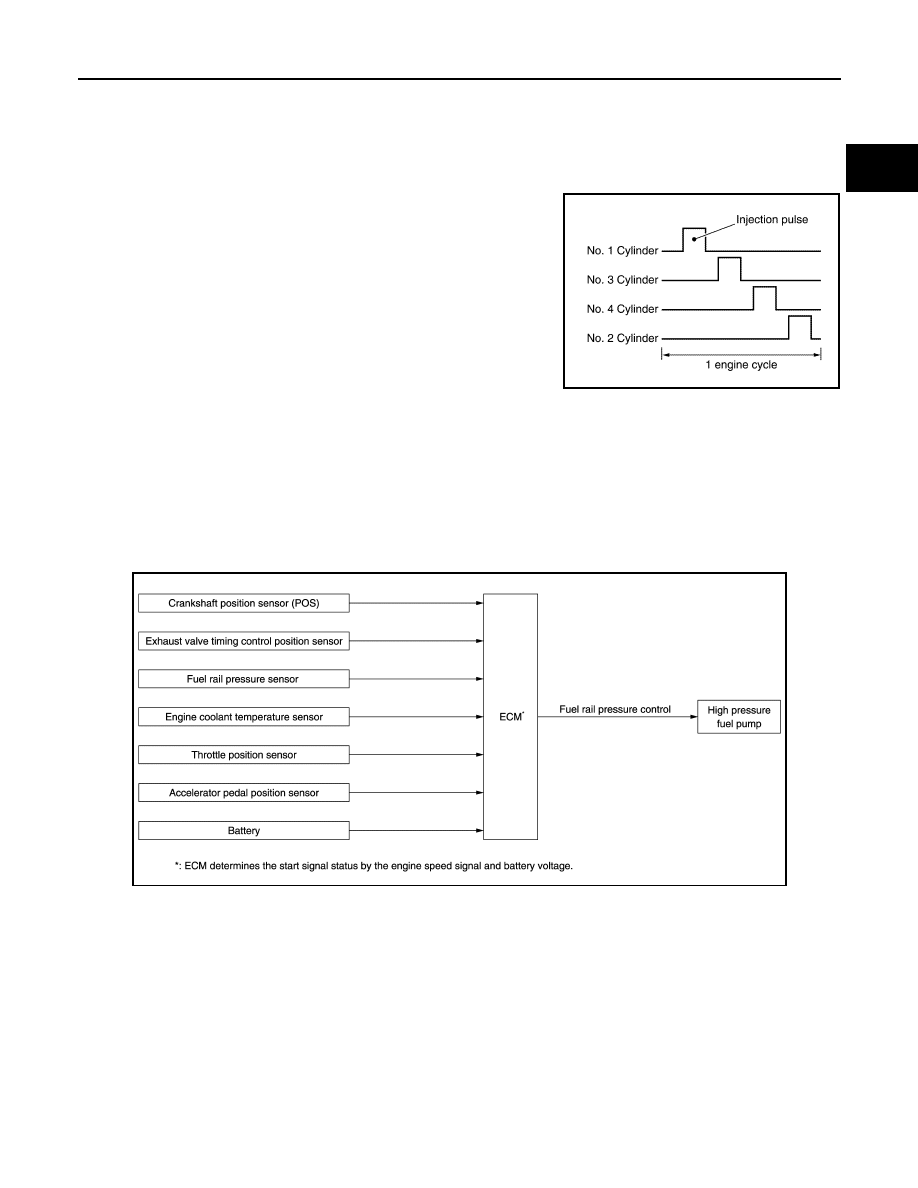

FUEL INJECTION TIMING

Sequential Direct Injection Gasoline System

Fuel is injected into each cylinder during each engine cycle accord-

ing to the ignition order.

STRATIFIED-CHARGE START CONTROL

The use of the stratified-charge combustion method enables emissions-reduction when starting the engine

with engine coolant temperature between 5

°C (41°F) and 40°C (104°F).

FUEL SHUT-OFF

Fuel to each cylinder is shut-off during deceleration, operation of the engine at excessively high speed or oper-

ation of the vehicle at excessively high speed.

FUEL PRESSURE CONTROL

FUEL PRESSURE CONTROL : System Diagram

INFOID:0000000012198203

FUEL PRESSURE CONTROL : System Description

INFOID:0000000012198204

INPUT/OUTPUT SIGNAL CHART

JPBIA4704GB

JPBIA4920GB