Nissan Juke F15. Manual - part 413

P1553 BATTERY CURRENT SENSOR

EC-465

< DTC/CIRCUIT DIAGNOSIS >

[MR FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

2. Also check harness for short to ground and to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace error-detected parts

5.

CHECK BATTERY CURRENT SENSOR

Check the battery current sensor. Refer to

EC-459, "Component Inspection"

.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-45, "Intermittent Incident"

.

NO

>> Replace battery negative cable assembly. Refer to

Component Inspection

INFOID:0000000012198017

1.

CHECK BATTERY CURRENT SENSOR

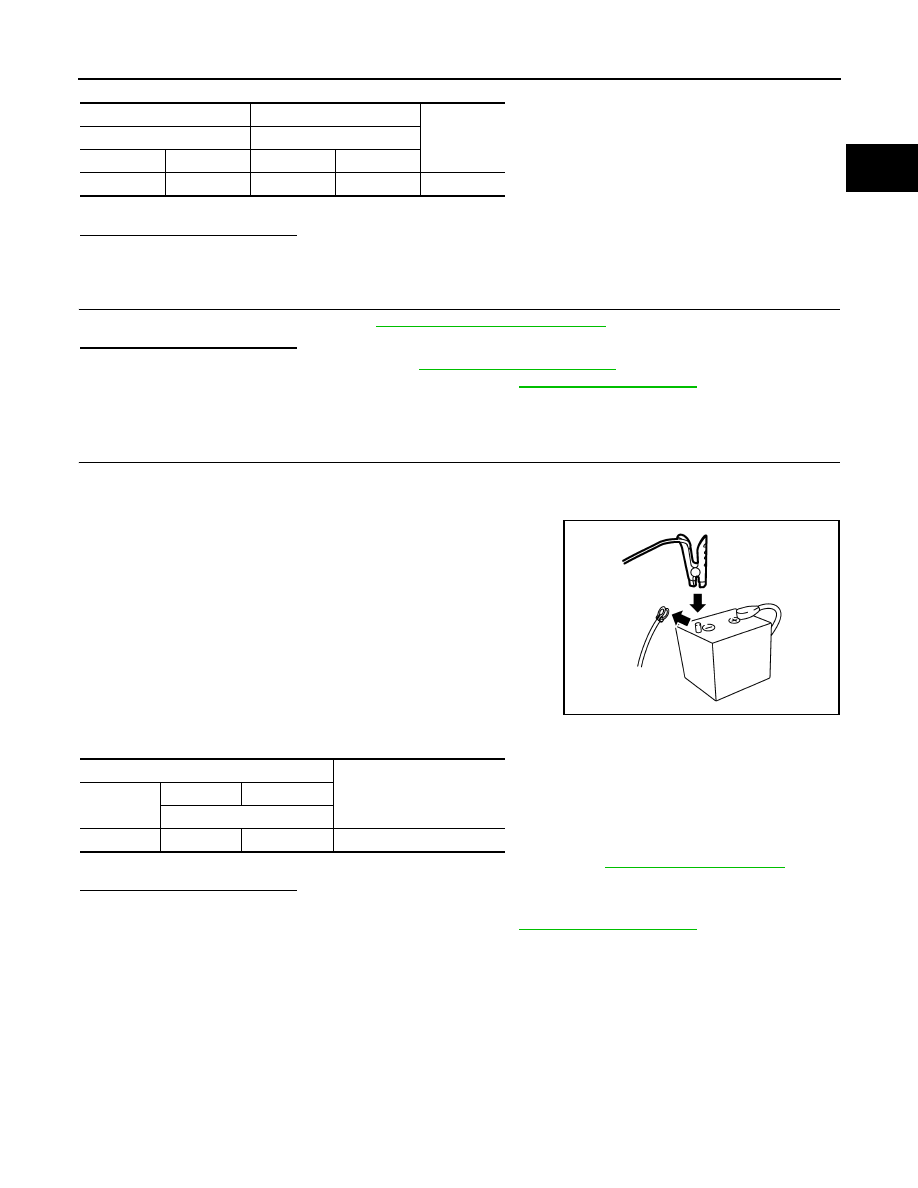

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect battery negative cable.

4. Install jumper cable between battery negative terminal and body

ground.

5. Turn ignition switch ON.

6. Check the voltage between ECM harness connector and

ground.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to

PG-97, "How to Handle Battery"

.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace battery negative cable assembly. Refer to

+

−

Continuity

Battery current sensor

ECM

Connector

Terminal

Connector

Terminal

F52

4

F26

80

Existed

JPBIA3286ZZ

ECM

Voltage

(Approx.)

Connector

+

-

Terminal

F26

80

87

2.5 V