Nissan Juke F15. Manual - part 320

DIAGNOSIS SYSTEM (ECM)

EC-93

< SYSTEM DESCRIPTION >

[MR FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

*: This function is not necessary in the usual service procedure.

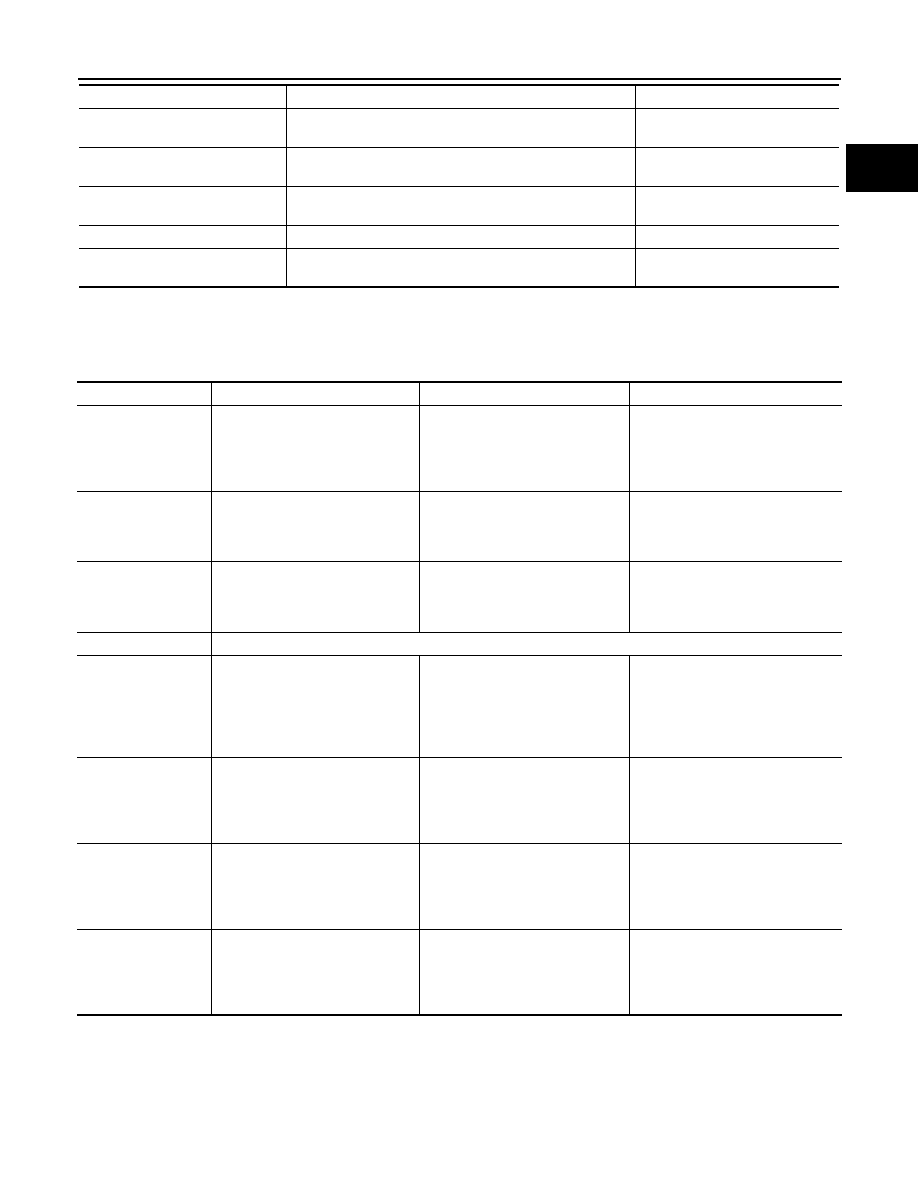

ACTIVE TEST MODE

Test Item

SELF-LEARNING CONT

The coefficient of self-learning control mixture ratio returns to

the original coefficient.

When clearing mixture ratio self-

learning value

G SENSOR CALIBRATION

• Park the vehicle on a flat road.

• Adjust pressure in all tires to the specified value.

Calibrates G sensor.

CLSD THL POS LEARN

• Ignition on and engine stopped.

When learning the throttle valve

closed position

SAVING DATA FOR REPLC CPU

In this mode, save data that is in ECM.

When ECM is replaced.

WRITING DATA FOR REPLC CPU

In this mode, write data stored by “SAVE DATA FOR CPU

REPLC” in work support mode to ECM.

When ECM is replaced.

Work item

Condition

Usage

Test item

Condition

Judgement

Check item (Remedy)

VENT CONTROL/V

• Ignition switch ON (Engine

stopped)

• Turn solenoid valve ON and OFF

with the CONSULT and listen to

operating sound.

Solenoid valve makes an operating

sound.

• Harness and connectors

• EVAP canister vent control sole-

noid valve

ENG COOLANT

TEMP

• Engine: Return to the original

trouble condition

• Change the engine coolant tem-

perature using CONSULT.

If trouble symptom disappears, see

CHECK ITEM.

• Harness and connectors

• Engine coolant temperature sen-

sor

• Fuel injector

FUEL INJECTION

• Engine: Return to the original

trouble condition

• Change the amount of fuel injec-

tion using CONSULT.

If trouble symptom disappears, see

CHECK ITEM.

• Harness and connectors

• Fuel injector

• Air fuel ratio (A/F) sensor 1

FUEL/T TEMP SEN

Change the fuel tank temperature using CONSULT.

PURG VOL CONT/V

• Engine: After warming up, run

engine at 1,500 rpm.

• Change the EVAP canister

purge volume control solenoid

valve opening percent using

CONSULT.

Engine speed changes according

to the opening percent.

• Harness and connectors

• Solenoid valve

FUEL PUMP RELAY

• Ignition switch: ON (Engine

stopped)

• Turn the fuel pump relay “ON”

and “OFF” using CONSULT and

listen to operating sound.

Fuel pump relay makes the operat-

ing sound.

• Harness and connectors

• Fuel pump relay

IGNITION TIMING

• Engine: Return to the original

trouble condition

• Timing light: Set

• Retard the ignition timing using

CONSULT.

If trouble symptom disappears, see

CHECK ITEM.

Perform Idle Air Volume Learning.

FAN DUTY CON-

TROL

*

• Ignition switch: ON

• Change duty ratio using CON-

SULT.

Cooling fan speed changes.

• Harness and connectors

• Cooling fan motor

• Cooling fan relay

• Cooling fan control module

• IPDM E/R