Nissan Juke F15. Manual - part 186

WATER OUTLET

CO-27

< REMOVAL AND INSTALLATION >

[MR FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

CO

N

P

O

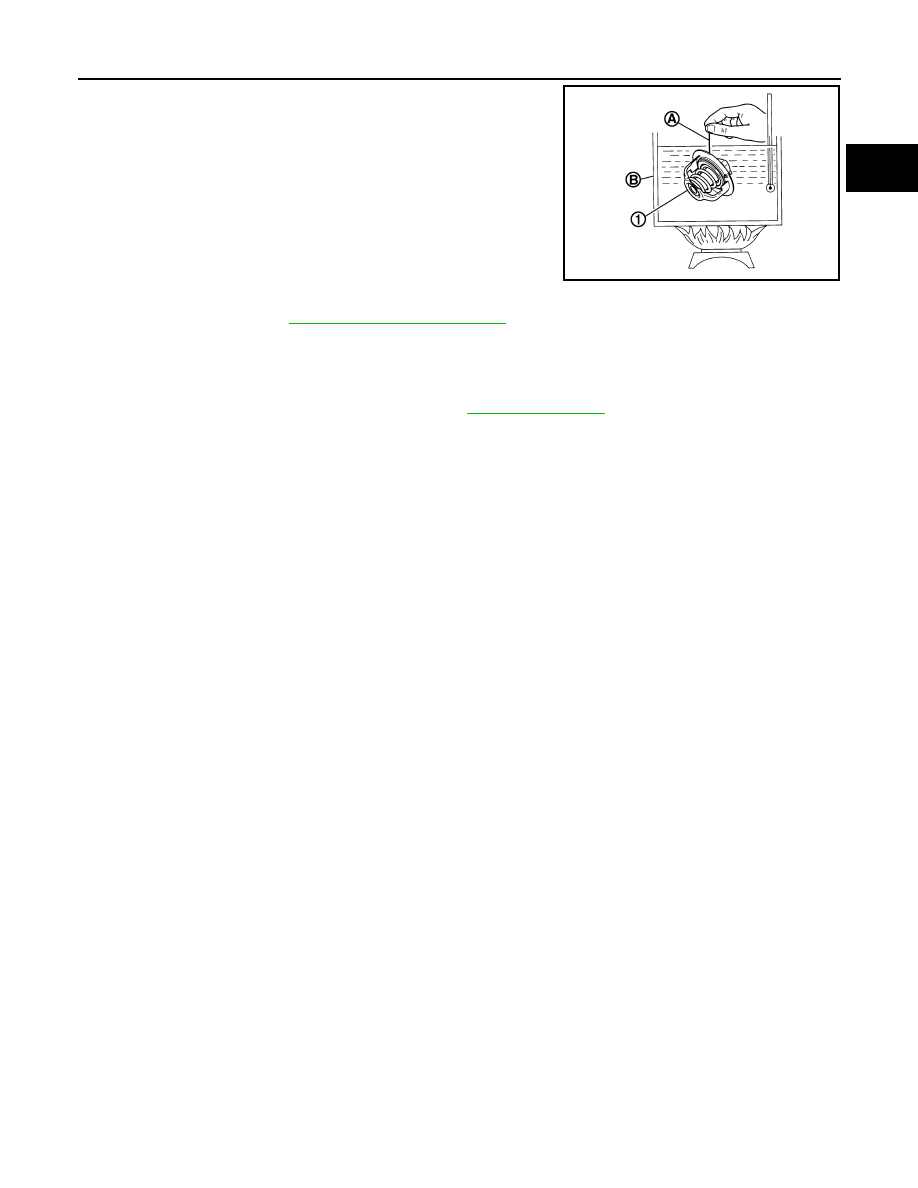

• Place a thread (A) so that it is caught in the valves of water control

valve (1). Immerse fully in a container (B) filled with water. Heat

while stirring.

• The valve opening temperature is the temperature at which the

valve opens and falls from the thread.

• Continue heating. Check the continuous valve lifting toward maxi-

mum valve lift.

NOTE:

The maximum valve lift amount standard temperature for water

control valve is the reference value.

• After checking the maximum valve lift amount, lower the water

temperature and check the valve closing temperature.

• If out of the standard, replace water control valve.

INSPECTION AFTER INSTALLATION

• Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to

• Start and warm up the engine. Check visually that there is no leakage of engine coolant.

Standard:

Refer to

.

PBIC3314J