Content .. 1069 1070 1071 1072 ..

Nissan Juke F15. Manual - part 1071

POWER WINDOW MOTOR

PWC-37

< DTC/CIRCUIT DIAGNOSIS >

C

D

E

F

G

H

I

J

L

M

A

B

PWC

N

O

P

REAR LH : Component Function Check

INFOID:0000000012196928

1.

CHECK FUNCTION

Check rear power window motor LH operation with rear power window switch LH or power window main

switch (rear LH switch).

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Refer to

PWC-37, "REAR LH : Diagnosis Procedure"

.

REAR LH : Diagnosis Procedure

INFOID:0000000012196929

1.

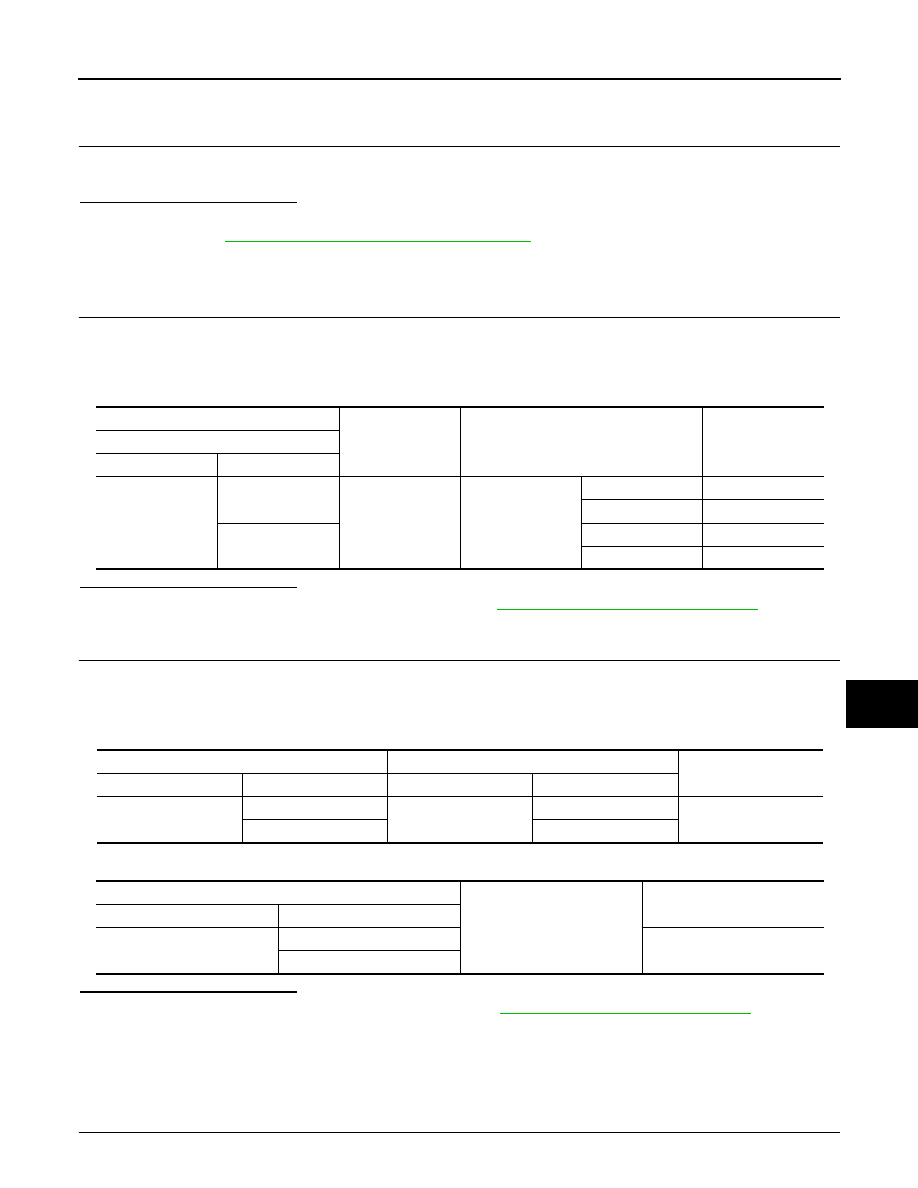

CHECK REAR POWER WINDOW MOTOR LH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear power window motor LH connector.

3. Turn ignition switch ON.

4. Check voltage between rear power window motor LH harness connector and ground.

Is the inspection result normal?

YES

>> Replace rear power window motor LH. Refer to

GW-23, "Disassembly and Assembly"

.

NO

>> GO TO 2.

2.

CHECK REAR POWER WINDOW MOTOR LH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear power window switch LH connector.

3. Check continuity between rear power window motor LH harness connector and rear power window switch

LH harness connector.

4. Check continuity between rear power window motor LH connector and ground.

Is the inspection result normal?

YES

>> Replace rear power window switch LH. Refer to

PWC-54, "Removal and Installation"

.

NO

>> Repair or replace harness.

REAR RH

REAR RH : Component Function Check

INFOID:0000000012196930

1.

CHECK FUNCTION

(+)

(-)

Condition

Voltage (V)

Rear power window motor LH

Connector

Terminal

D67

1

Ground

Rear power win-

dow switch LH

NEUTRAL

0 – 1

DOWN

9 – 16

3

NEUTRAL

0 – 1

UP

9 – 16

Rear power window motor LH

Rear power window switch LH

Continuity

Connector

Terminal

Connector

Terminal

D67

1

D63

4

Existed

3

5

Rear power window motor LH

Ground

Continuity

Connector

Terminal

D67

1

Not existed

3