содержание .. 944 945 946 947 ..

Nissan Tiida C11. Manual - part 946

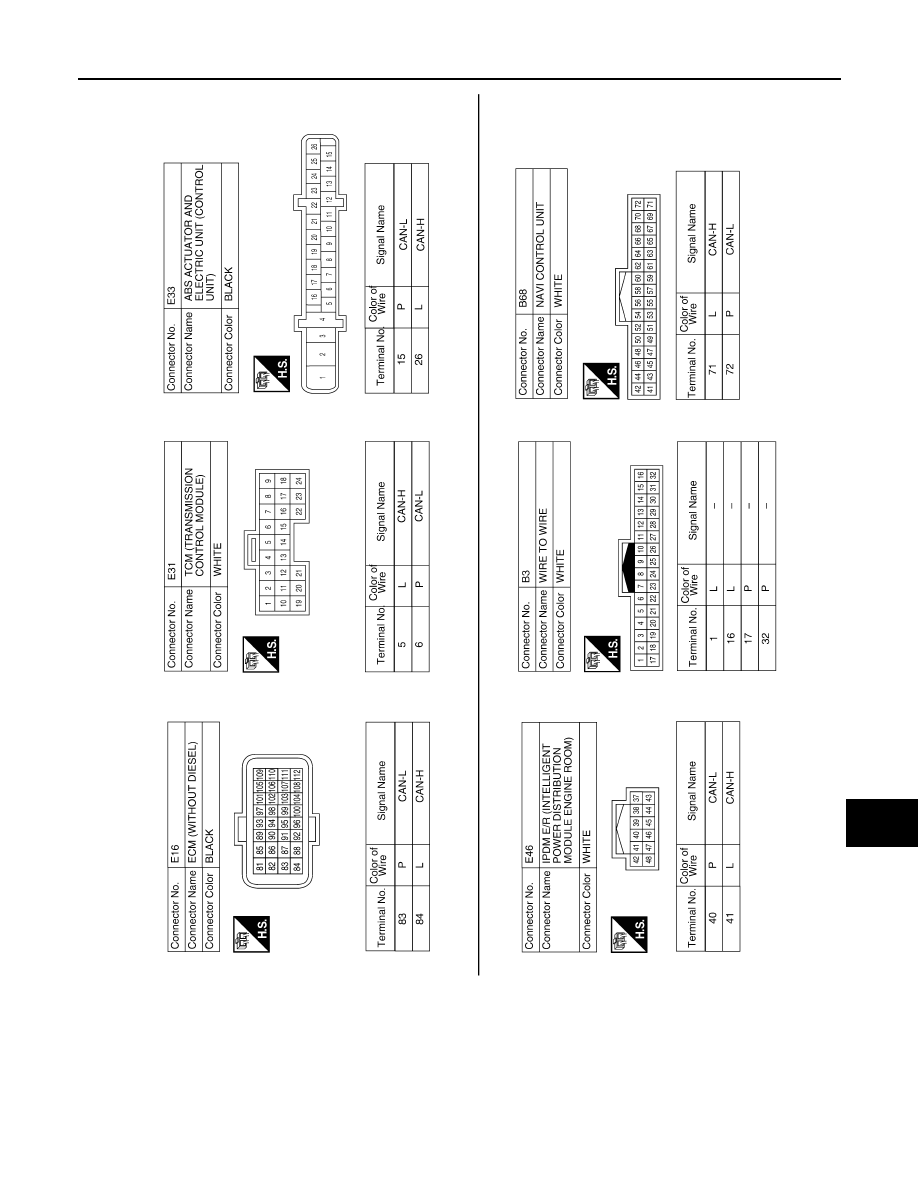

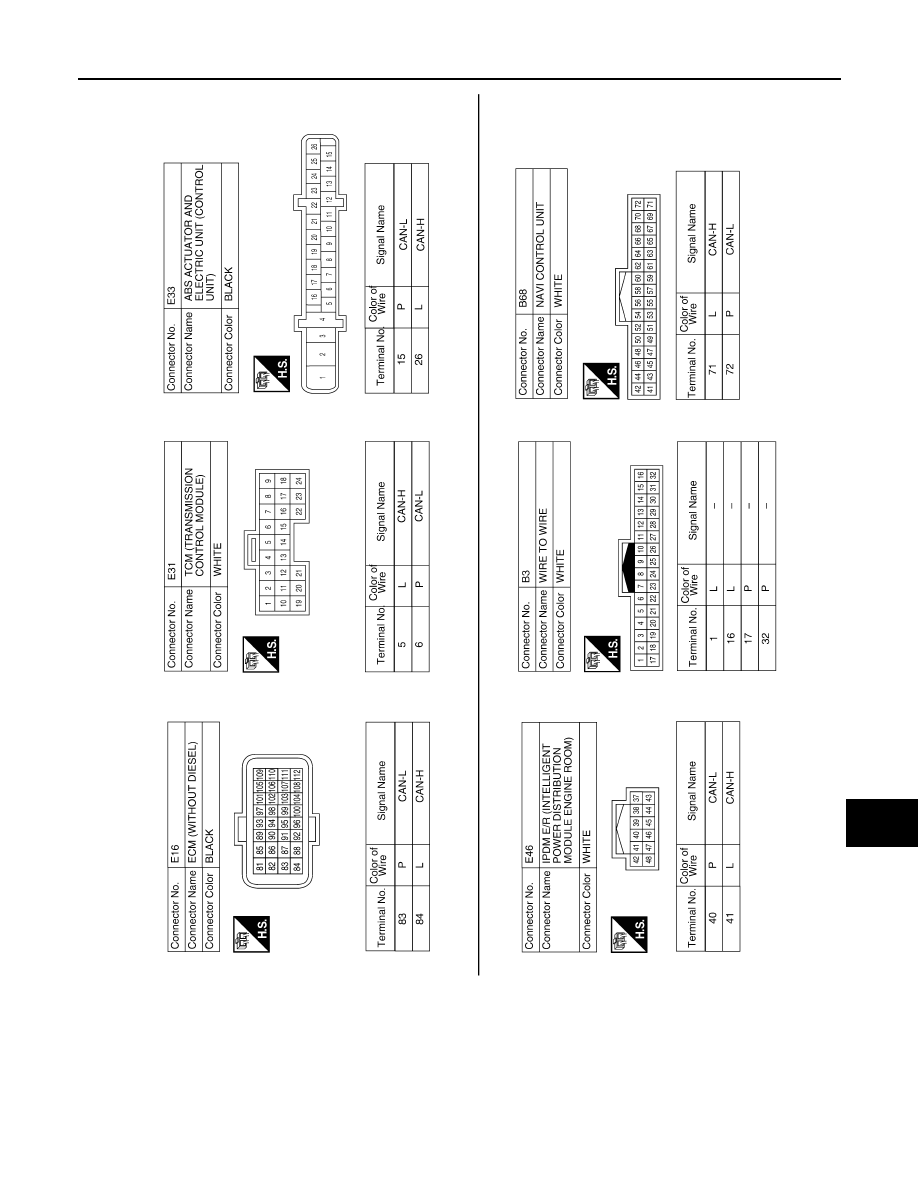

LAN

CAN COMMUNICATION SYSTEM

LAN-41

< COMPONENT DIAGNOSIS >

[CAN]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

ALMIA0182GB

|

|

|

содержание .. 944 945 946 947 ..

LAN CAN COMMUNICATION SYSTEM LAN-41 < COMPONENT DIAGNOSIS > [CAN] C D E F G H I J K L B A O P N ALMIA0182GB |