содержание .. 726 727 728 729 ..

Nissan Tiida C11. Manual - part 728

EM-264

< ON-VEHICLE MAINTENANCE >

[K9K]

DRIVE BELTS

4.

Remove drive belt.

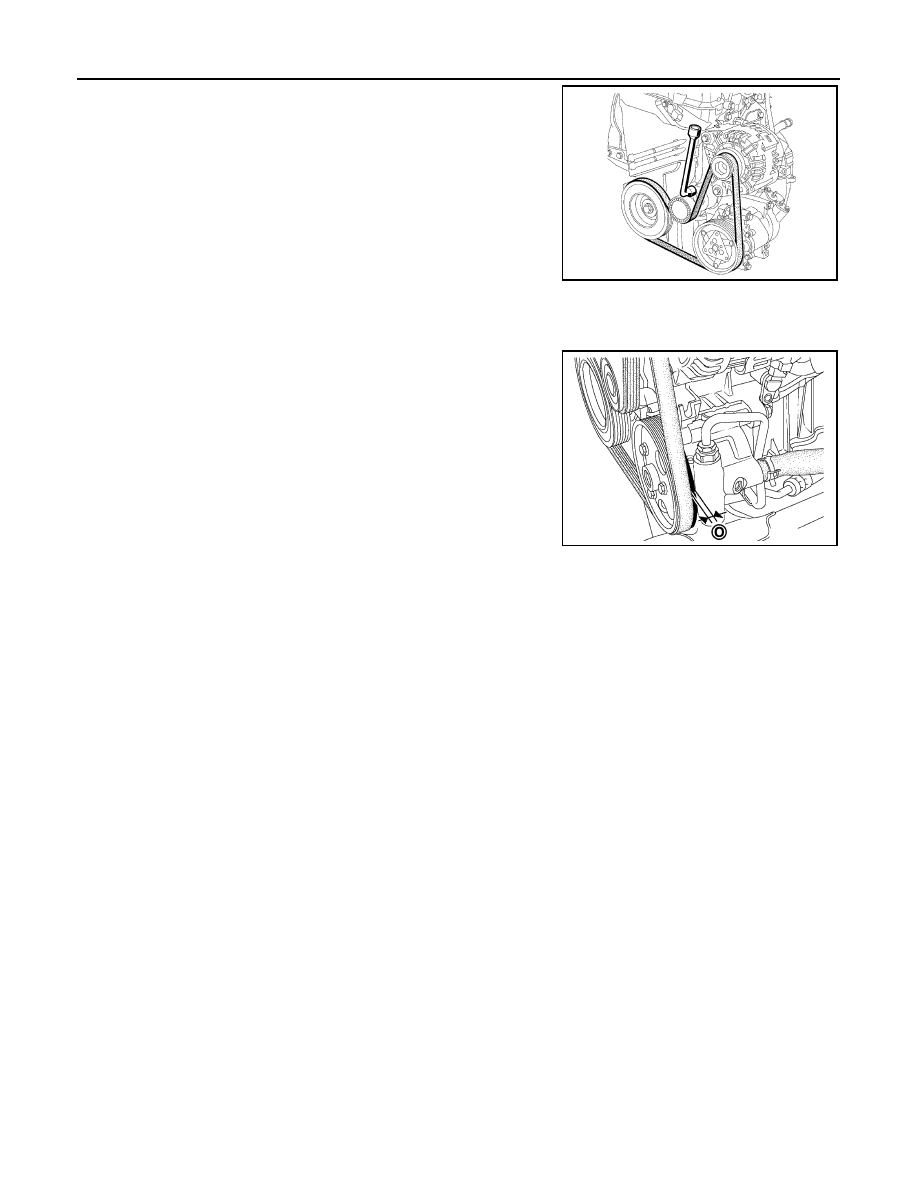

• Turn drive belt auto-tensioner adjusting bolt clockwise to

release drive belt tension.

INSTALLATION

1.

Install the drive belt.

CAUTION:

• Make sure drive belt is correctly engaged with the pulley

groove.

• Check for oil and coolant on drive belt and each pulley

groove.

• Certain drive belts have five teeth whereas the air condi-

tioning compressor pulley, power-assisted steering pump

pulley, and generator pulley all have six teeth.In this case,

it is essential to check that inner tooth (O) of the pulleys

remains free when fitting the drive belt.

Never turn the engine in the opposite direction to its nor-

mal operating direction.

Use a brush to remove any deposits from the crankshaft

pulley V grooves.

2.

Release drive belt auto-tensioner, and apply tension to drive belt.

3.

Turn crankshaft pulley clockwise several times to equalize tension between each pulley.

MBIB0353E

MBIB0516E