содержание .. 710 711 712 713 ..

Nissan Tiida C11. Manual - part 712

EM-200

< ON-VEHICLE REPAIR >

[MR18DE]

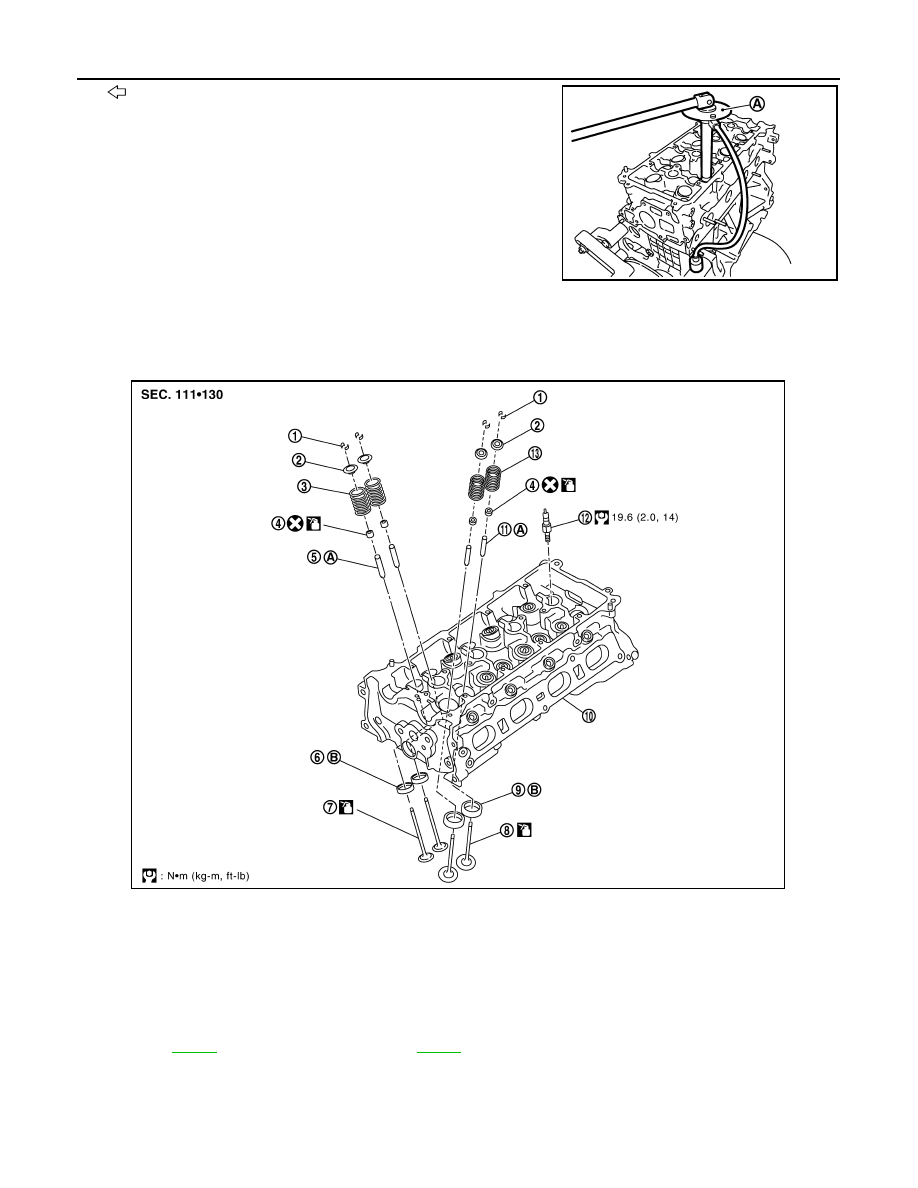

CYLINDER HEAD

: Engine front

CAUTION:

Check and confirm the tightening angle by using Tool (A) or

protractor. Never judge by visual inspection without the

tool.

4.

Installation of the remaining components is in the reverse order of removal.

Component

INFOID:0000000001337806

Disassembly and Assembly

INFOID:0000000001337807

DISASSEMBLY

Tool number

: KV10112100 (BT-8653-A)

PBIC3208J

1.

Valve collet

2.

Valve spring retainer

3.

Valve spring (EXH)

(with valve spring seat)

4.

Valve oil seal

5.

Valve guide (EXH)

6.

Valve seat (EXH)

7.

Valve (EXH)

8.

Valve (INT)

9.

Valve seat (INT)

10. Cylinder head

11. Valve guide (INT)

12. Spark plug

13.

Valve spring (INT)

(with valve spring seat)

A.

B.

Refer to

PBIC3543J