содержание .. 706 707 708 709 ..

Nissan Tiida C11. Manual - part 708

EM-184

< ON-VEHICLE REPAIR >

[MR18DE]

TIMING CHAIN

Be sure O-rings a aligned properly.

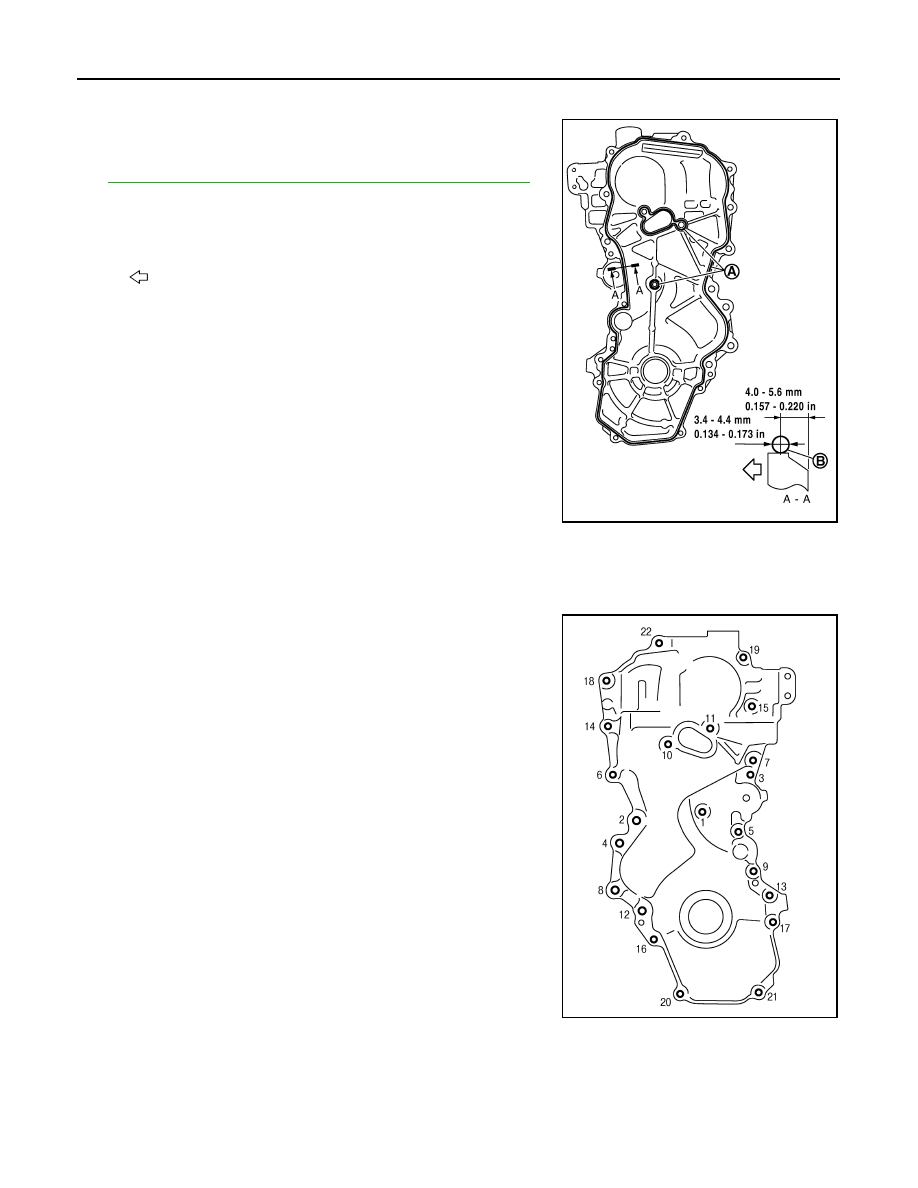

13. Apply the sealant without breaks to the specified location using

Tool.

Use Genuine Silicone RTV Sealant or equivalent. Refer to

GI-27, "Recommended Chemical Products and Sealants"

.

14. Make sure that matching marks of timing chain and each sprocket are still aligned.

CAUTION:

• Make sure O-ring on cylinder block is correctly installed.

• Be careful not to damage front oil seal by interference with front end of crankshaft.

15. Install front cover, and tighten bolts in numerical order as shown.

CAUTION:

Attaching should be done within 5 minutes after liquid gas-

ket application.

NOTE:

Follow the installation position of bolts as shown.

16. Tighten all bolts are in two stages to specified torque in numeri-

cal order as shown.

CAUTION:

Be sure to wipe off any excessive liquid gasket leaking.

17. Install crankshaft pulley.

CAUTION:

• Never damage front oil seal lip section.

• If needed use a plastic hammer, tap on its center portion (not circumference) to seat crankshaft

pulley.

Tool number

WS39930000 (

–

)

A

: Liquid gasket application area

: Engine outside

PBIC3959E

M6 bolts

:

No. 1

M10 bolts

:

No. 6, 7, 10, 11, 14

M12 bolts

:

No. 2, 4, 8, 12

M8 bolts

:

Except the above

PBIC3164J