содержание .. 659 660 661 662 ..

Nissan Tiida C11. Manual - part 661

EC-1294

< PRECAUTION >

[K9K]

PRECAUTIONS

General Precautions

INFOID:0000000001162746

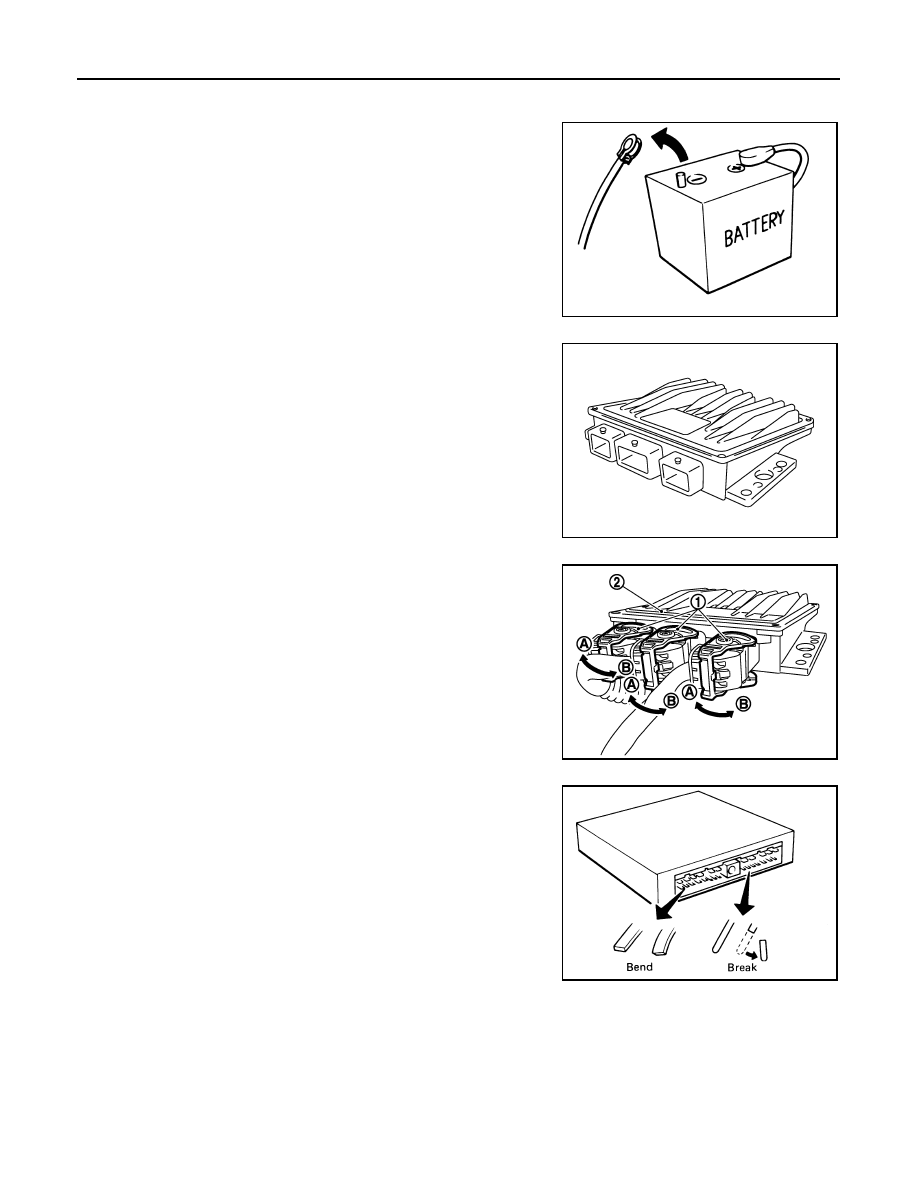

• Always use a 12 volt battery as power source.

• Do not attempt to disconnect battery cables while engine is

running.

• Before connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF, wait 3 minutes and discon-

nect battery negative cable. Failure to do so may damage the

ECM because battery voltage is applied to ECM even if igni-

tion switch is turned OFF.

• Before removing parts, turn ignition switch OFF and then dis-

connect battery negative cable.

• Do not disassemble ECM.

• When connecting ECM harness connector, fasten (A) it

securely with levers (1) as far as they will go as shown in the

figure.

- ECM (2)

- Loosen (B)

• When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM pin

terminal, when connecting pin connectors.

• Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge) volt-

age to develop in coil and condenser, thus resulting in dam-

age to IC's.

• Keep engine control system harness at least 10cm (4 in) away

from adjacent harness, to prevent engine control system mal-

functions due to receiving external noise, degraded operation

of IC's, etc.

• Keep engine control system parts and harness dry.

• Handle mass air flow sensor carefully to avoid damage.

• Do not disassemble mass air flow sensor.

• Do not clean mass air flow sensor with any type of detergent.

• Even a slight leak in the air intake system can cause serious incidents.

• Do not shock or jar the camshaft position sensor, crankshaft position sensor.

SEF289H

MBIB1517E

MBIB1518E

SEF291H