содержание .. 394 395 396 397 ..

Nissan Tiida C11. Manual - part 396

EC-234

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

P1143 HO2S1

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

Do you have CONSULT-III?

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Start engine and warm it up to normal operating temperature.

2.

Stop engine and wait at least 10 seconds.

3.

Turn ignition switch ON and select “HO2S1 (B1) P1143” of “HO2S1” in “DTC WORK SUPPORT” mode

with CONSULT-III.

4.

Touch “START”.

5.

Start engine and let it idle for at least 3 minutes.

NOTE:

Never raise engine speed above 3,600 rpm after this step. If the engine speed limit is exceeded,

return to step 5.

6.

When the following conditions are met, “TESTING” will be displayed on the CONSULT-III screen. Maintain

the conditions continuously until “TESTING” changes to “COMPLETED”. (It will take approximately 50

seconds or more.)

CAUTION:

Always drive vehicle at a safe speed.

If “TESTING” is not displayed after 5 minutes, retry from step 2.

7.

Touch “SELF-DIAG RESULT”

Which is displayed on CONSULT-III screen?

OK

>> INSPECTION END

NG

>> Go to

3.

PERFORM COMPONENT FUNCTION CHECK

With GST

1.

Start engine and warm it up to normal operating temperature.

2.

Set voltmeter probes between ECM harness connector terminals as follows under the following condition.

NOTE:

Use component function check to check the overall function of the heated oxygen sensor 1 circuit. During this

check, a 1st trip DTC might not be confirmed.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Go to

Diagnosis Procedure

INFOID:0000000001671006

1.

CHECK GROUND CONNECTION

1.

Turn ignition switch OFF.

2.

Check ground connection E15. Refer to Ground Inspection in

.

Is the inspection result normal?

ENG SPEED

1,375 - 2,600 rpm

VHCL SPEED SE

Less than 100 km/h (62 MPH)

B/FUEL SCHDL

3.7 - 10.0 msec

Shift lever

Suitable position

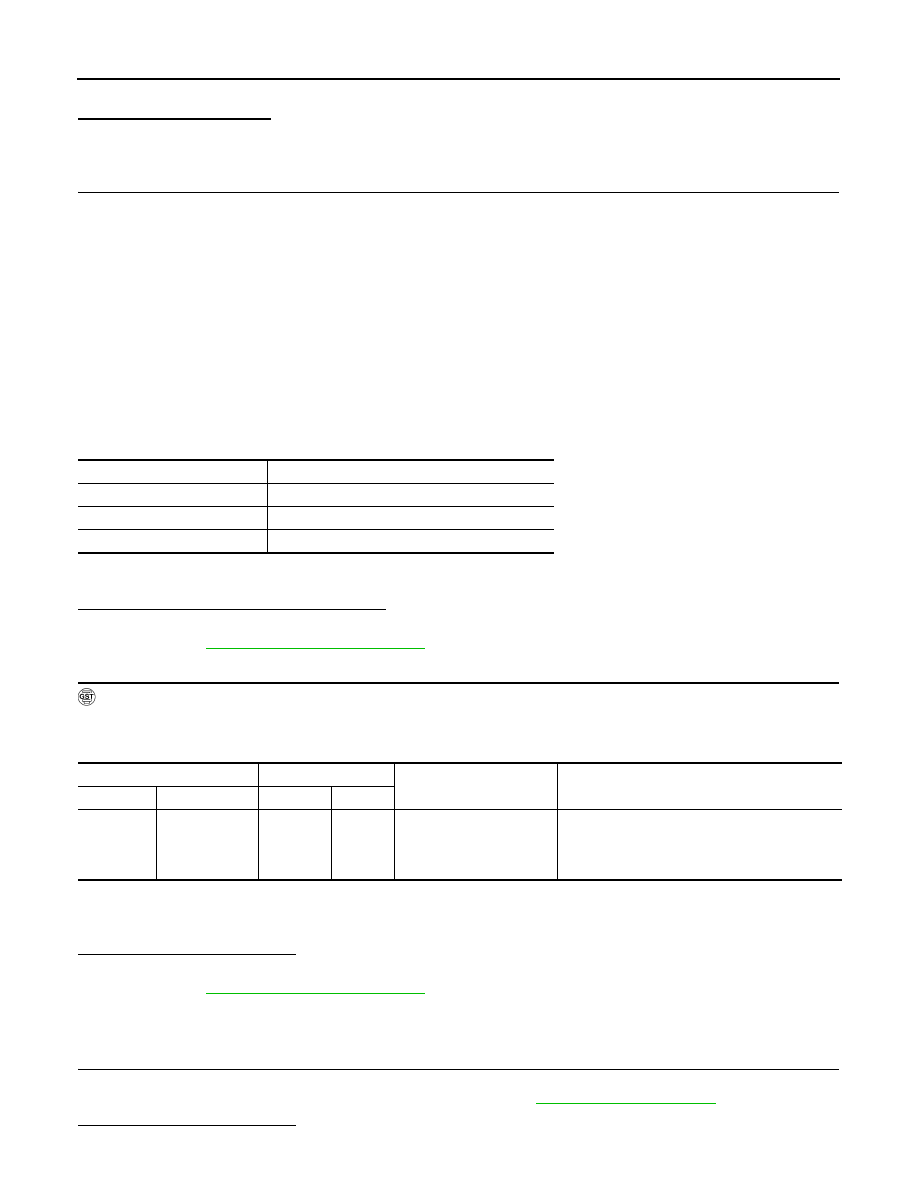

ECM

Ground

Condition

Voltage

Connector

Terminal

Connector

Terminal

F11

49

(HO2S1 signal)

F11

56

Engine speed held at

2,000 rpm constant under

no load

• The maximum voltage is over 0.6 at least 1

time.

• The minimum voltage is over 0.1 at least 1

time.