содержание .. 1411 1412 1413 1414 ..

Nissan Tiida C11. Manual - part 1413

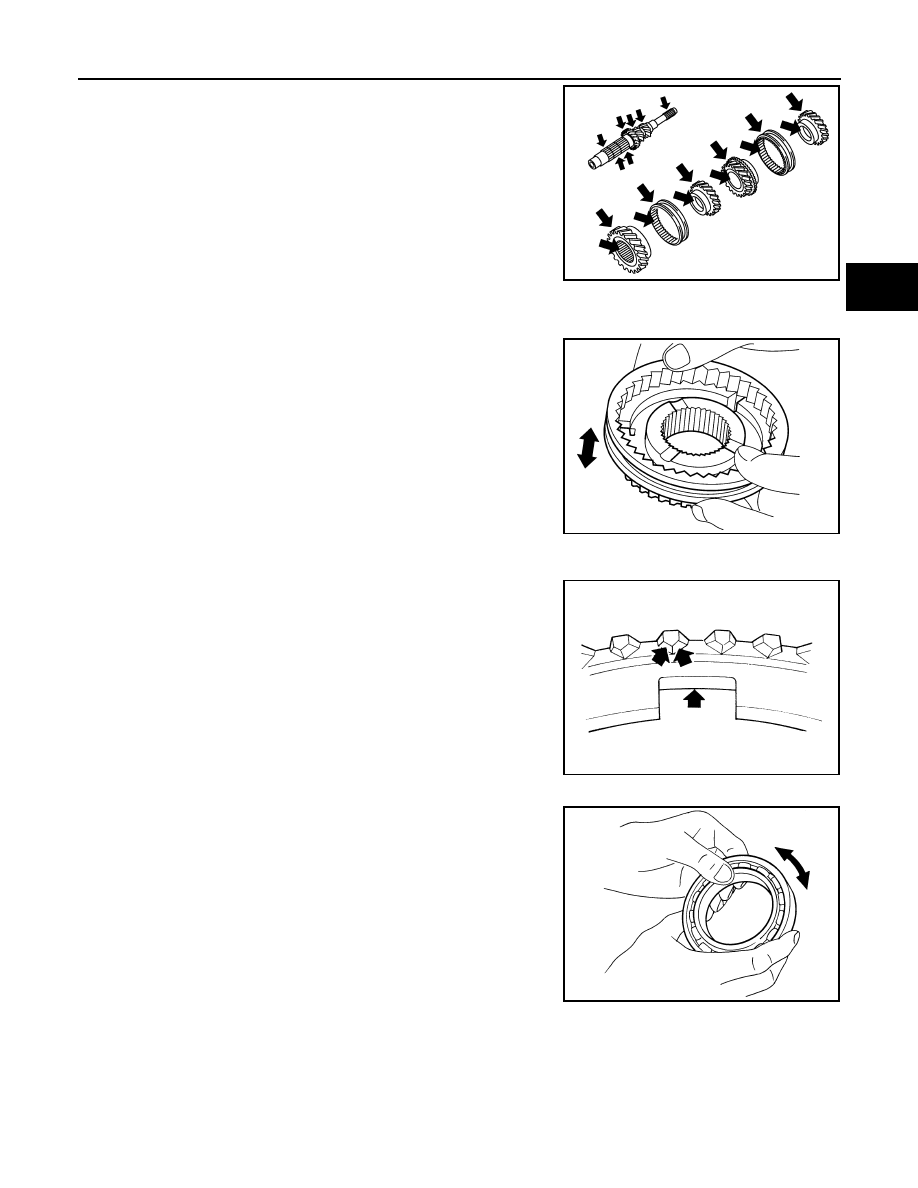

INPUT SHAFT AND GEAR

TM-703

< DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F94R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

Check items below. If necessary, replace them with new ones.

• Damage, peeling, dent, uneven wear, bending, and other non-

standard conditions of the shaft.

• Excessive wear, damage, peeling, and other non-standard condi-

tions of the gears.

SYNCHRONIZER

Synchronizer Hub and Coupling Sleeve

Check items below. If necessary, replace them with new ones.

• Damage and excessive wear of contact surfaces of coupling

sleeve, synchronizer hub and insert key.

• Coupling sleeve and synchronizer hub must move smoothly.

Baulk Ring

Check items below. If necessary, replace them with new ones.

• If any crack, damage, or excessive wear is found on cam face of

baulk ring or working face of insert, replace it.

BEARING

Check items below. If necessary, replace them with new ones.

• Damage and rough rotation of bearing

SCIA7736E

SCIA1753J

SCIA0608J

MTF0041D