содержание .. 1320 1321 1322 1323 ..

Nissan Tiida C11. Manual - part 1322

A/T CONTROL SYSTEM

TM-339

< FUNCTION DIAGNOSIS >

[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

*1: Spare for vehicle speed sensor·A/T (revolution sensor)

*2: Spare for accelerator pedal position signal

*3: If these input and output signals are different, the TCM triggers the fail-safe function.

*4: Used as a condition for starting self-diagnostics; if self-diagnosis are not started, it is judged that there is some kind of error.

*5: Input by CAN communications.

*6: Output by CAN communications.

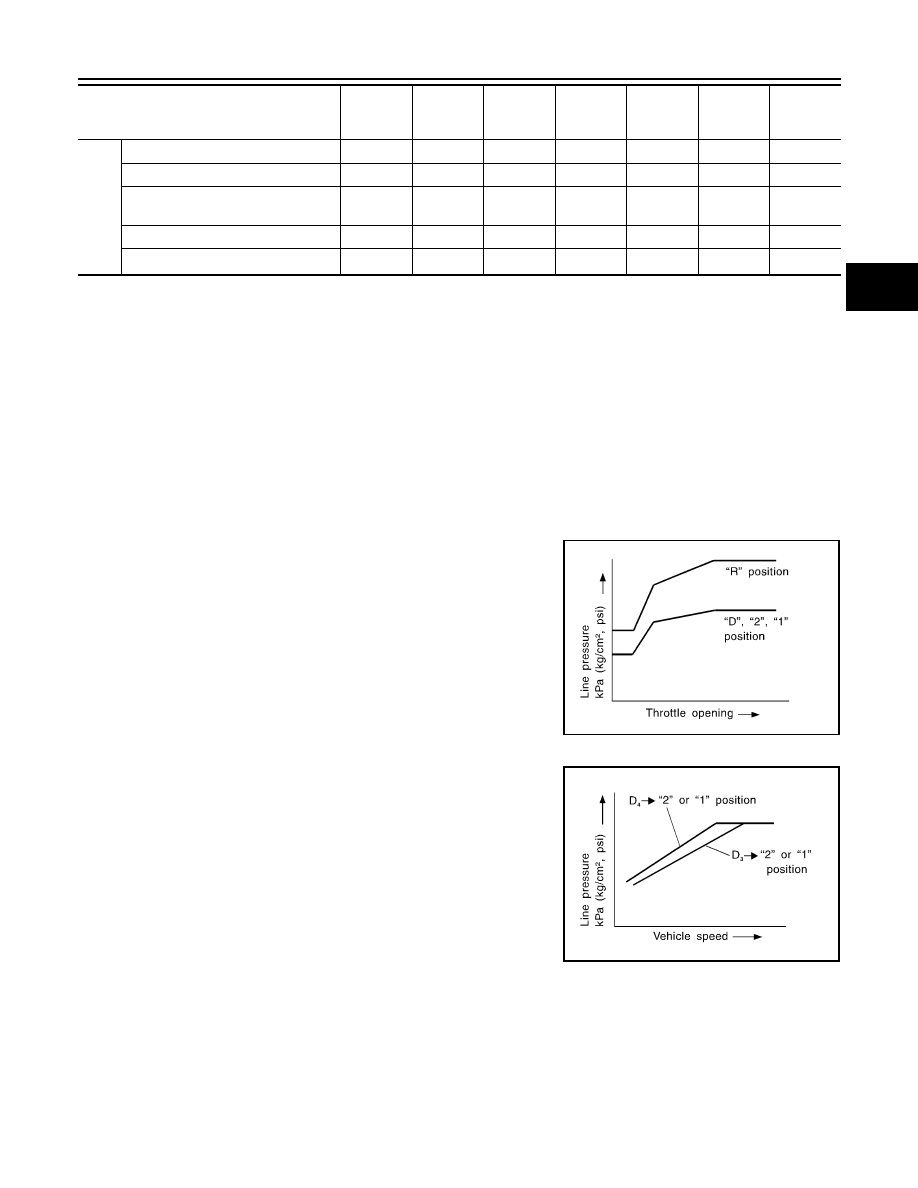

Line Pressure Control

INFOID:0000000001714314

• TCM has various line pressure control characteristics to match the driving conditions.

• An ON-OFF duty signal is sent to the line pressure solenoid valve based on TCM characteristics.

• Hydraulic pressure on the clutch and brake is electronically controlled through the line pressure solenoid

valve to accommodate engine torque. This results in smooth shift operation.

NORMAL CONTROL

The characteristic of the line pressure to the throttle opening is set

for suitable clutch operation.

BACK-UP CONTROL (ENGINE BRAKE)

If the selector lever is shifted to “2” position while driving in D

4

or D

3,

great driving force is applied to the clutch inside the transaxle. Clutch

operating pressure (line pressure) must be increased to deal with

this driving force.

DURING SHIFT CHANGE

Out-

put

Shift solenoid valve A/B

X

(*3) X

X

Line pressure solenoid

X

(*3) X

X

Torque converter clutch solenoid

valve

X

(*3) X

X

Overrun clutch solenoid valve

X

X

(*3) X

X

OD OFF indicator lamp

(*6)

X

X

Control item

Line

pressure

control

Vehicle

speed

control

Shift

control

Lock-up

control

Engine

brake

control

Fail-safe

function

Self-diag-

nostics

function

SAT003J

SAT004J