содержание .. 1297 1298 1299 1300 ..

Nissan Tiida C11. Manual - part 1299

REPAIR FOR COMPONENT PARTS

TM-247

< DISASSEMBLY AND ASSEMBLY >

[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

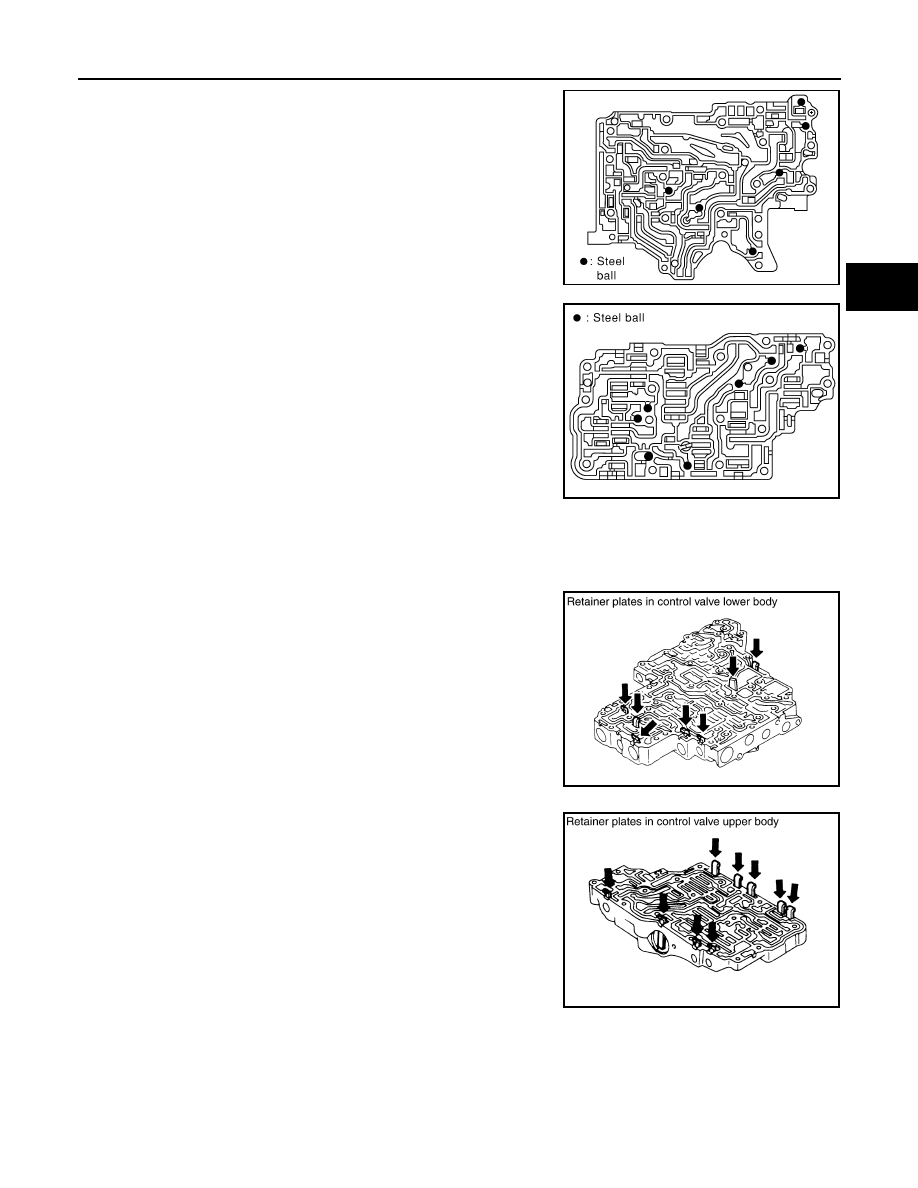

12. Check to see that steel balls are properly positioned in control

valve inter body and then remove them.

CAUTION:

Do not lose steel balls.

13. Check to see that steel balls are properly positioned in control

valve upper body and then remove them.

CAUTION:

Do not lose steel balls.

INSPECTION

Control Valve Lower and Upper Bodies

CAUTION:

Do not lose these parts.

• Check to see that retainer plates are properly positioned in control

valve lower body.

• Check to see that retainer plates are properly positioned in control

valve upper body.

Oil Strainer

SAT870J

SAT871J

SCIA4978E

SCIA4979E