содержание .. 1056 1057 1058 1059 ..

Nissan Tiida C11. Manual - part 1058

LU-22

< SERVICE DATA AND SPECIFICATIONS (SDS)

[MR18DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and Limit

INFOID:0000000001337830

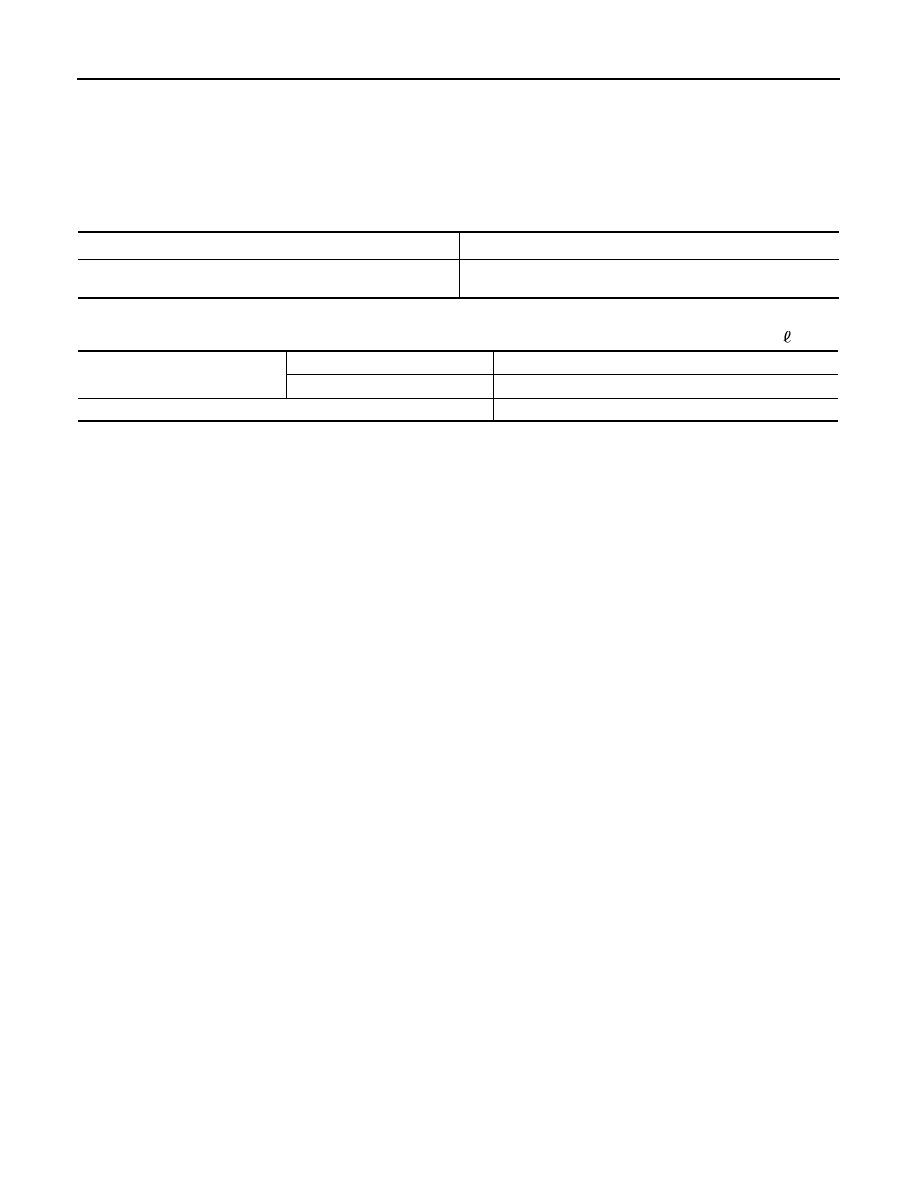

OIL PRESSURE

Oil Capacity

Unit:

(Imp qt)

Engine speed rpm

Approximate discharge pressure kPa (bar, kg/cm

2

, psi)

Idle speed

2,000

71.5 (0.70, 0.70, 10)

200 (2.0, 2.0, 29)

Drain and refill

With oil filter change

Approximately 4.4 (3 7/8)

Without oil filter change

Approximately 4.2 (3 3/4)

Dry engine (engine overhaul)

Approximately 5.5 (4 7/8)