Mitsubishi Outlander XL. Manual - part 698

ZC601123

2

0000

1

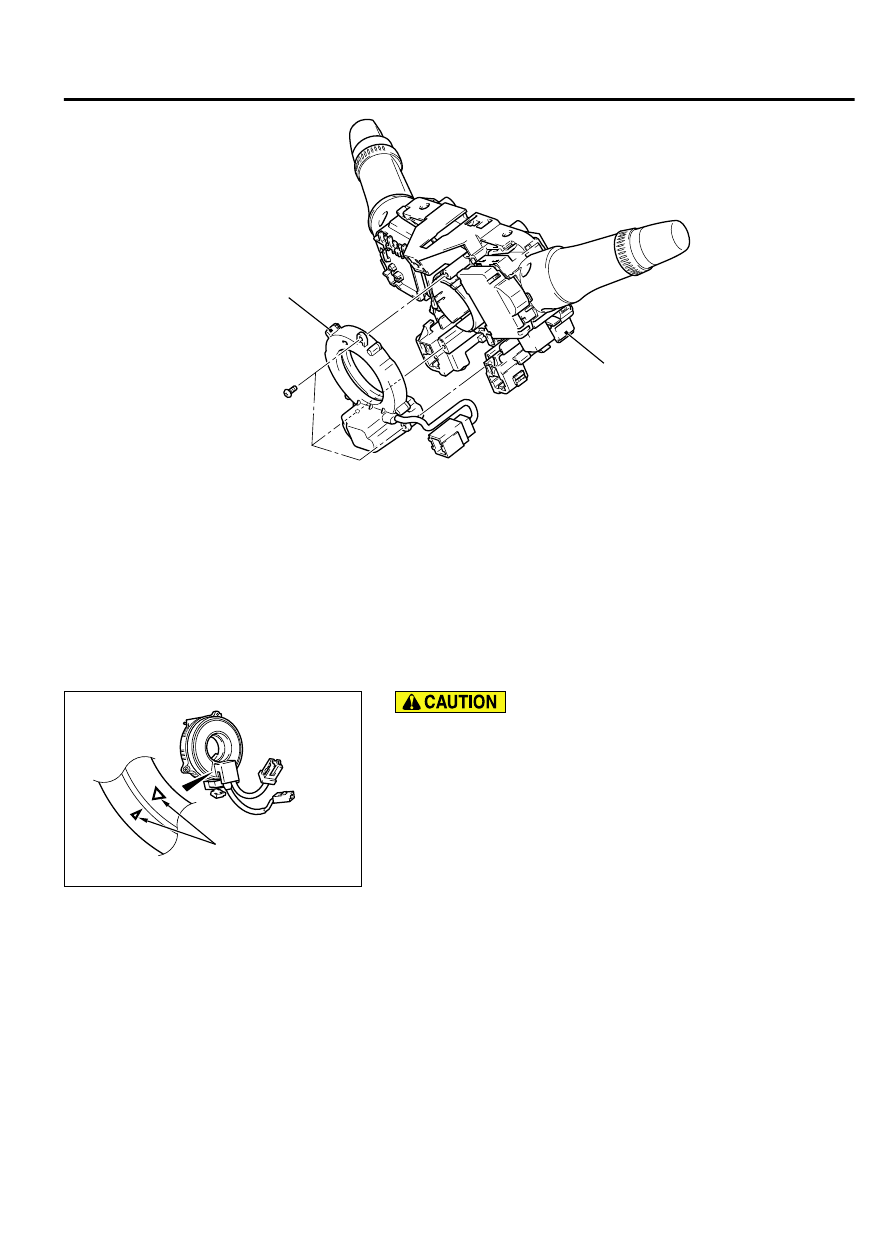

Removal steps

·

Position the front wheels in a

straight ahead direction.

>>A<<

1. Clock

spring/column

switch

assembly (Refer to GROUP 52B

- SRS Control Unit P.52B-326.)

Removal steps

>>A<<

2. Steering wheel sensor

INSTALLATION SERVICE POINTS

A NEUTRAL POSITIONING OF STEERING WHEEL SENSOR

ZC601124

Mating marks

0000

⦆

Always align the center of the clock spring before

installing the steering wheel sensor. Otherwise, the

sensor can be damaged.

⦆

If the center of the clock spring is not correctly aligned,

the steering wheel may not be turned fully or the cable

inside the clock spring may be broken, causing the SRS

air bag to be inoperative or operated incorrectly.

1.

Align the mating marks of the clock spring.

Alignment of mating marks

(1)

Turn the clock spring clockwise fully.

(2)

Turn the clock spring counterclockwise approximately

three and 3/4 turns to align the mating marks.

(3)

Install the clock spring to the column switch.

ACTIVE SKID CONTROL SYSTEM (ASC)

35C-199

STEERING WHEEL SENSOR