Mitsubishi Outlander XL. Manual - part 316

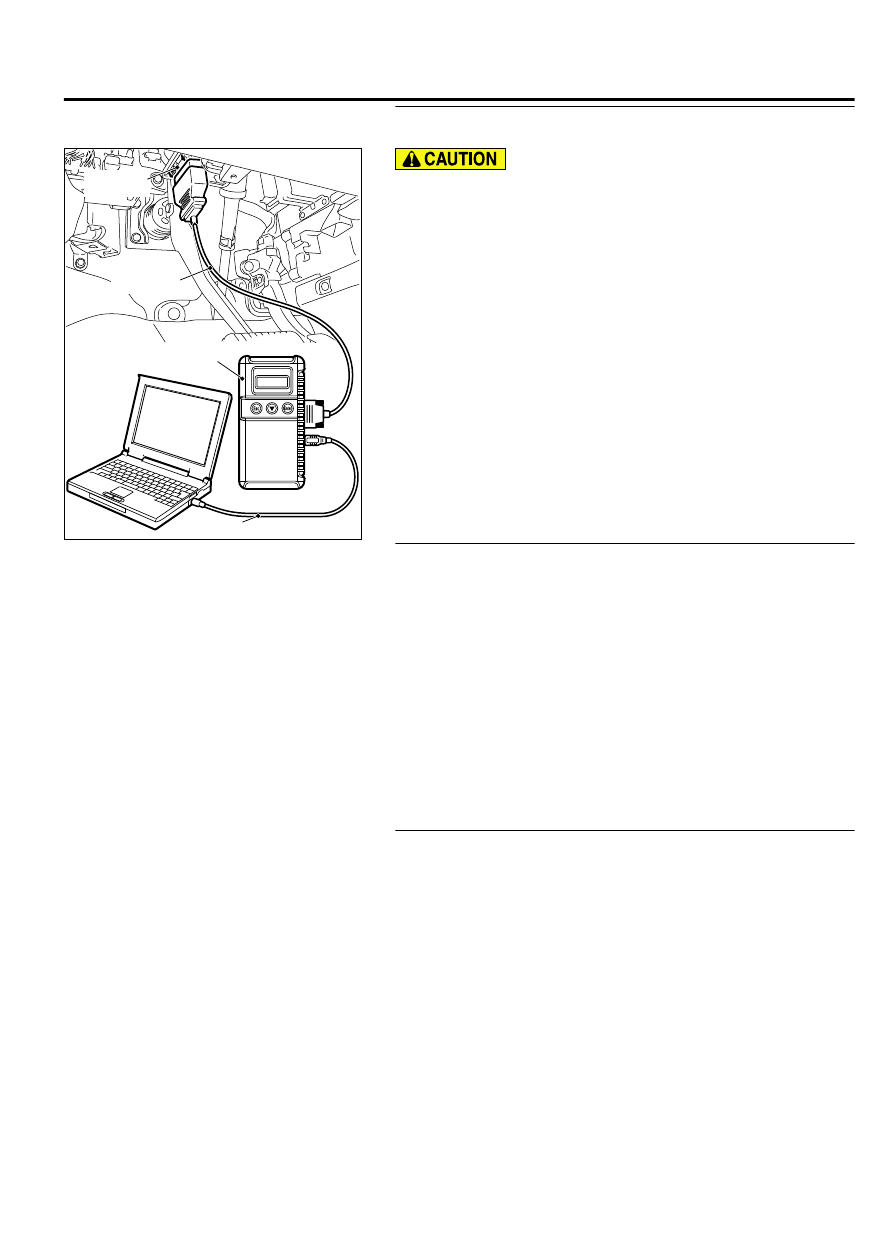

STEP 1. Using scan tool MB991958, read the diagnostic

trouble code (DTC).

ZC501967

AC404789

ZC5019680000

MB991824

MB991827

MB991910

Data link

connector

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before

connecting or disconnecting scan tool MB991958.

(1)

Connect scan tool MB991958 to the data link connector.

(2)

Turn the ignition switch to the "ON" position.

(3)

Read the DTC.

(4)

Turn the ignition switch to the "LOCK" (OFF) position.

Q:Is DTC P0451 set?

YES:

Refer to DTC P0451 - Evaporative Emission Control

System Pressure Sensor Range/Performance P.13Ab-495.

NO:

Go to Step 2.

STEP 2. Using scan tool MB991958, check data list item 52:

Fuel Tank Differential Pressure Sensor.

(1)

Turn the ignition switch to the "ON" position.

(2)

Remove the fuel cap.

(3)

Set scan tool MB991958 to the data reading mode for item

52, Fuel Tank Differential Pressure Sensor.

⦆

The fuel tank differential pressures should be 1,500 and

3,500 millivolts.

(4)

Turn the ignition switch to the "LOCK" (OFF) position.

Q:Is the fuel tank pressure between 1,500 and 3,500

millivolts?

YES:

Go to Step 3.

NO:

Refer to DTC P0451 - Evaporative Emission Control

System Pressure Sensor Range/Performance P.13Ab-495.

STEP 3. Using scan tool MB991958, check actuator test item

10: Evaporative Emission Purge Solenoid.

(1)

Turn the ignition switch to the "ON" position.

(2)

Set scan tool MB991958 to the actuator test mode for item

10, Evaporative emission purge solenoid.

⦆

An operation sound should be heard and vibration should

be felt when the evaporative emission purge solenoid is

operated.

(3)

Turn the ignition switch to the "LOCK" (OFF) position.

Q:Is the solenoid operating properly?

YES:

Go to Step 4.

NO:

Replace the evaporative emission purge solenoid.

Then go to Step 6.

MULTIPORT INJECTION SYSTEM (MFI) <DIAGNOSIS>

13Ab-459

DIAGNOSTIC TROUBLE CODE PROCEDURES