Content .. 1258 1259 1260 1261 ..

Mitsubishi Outlander XL. Manual - part 1260

System

Objective / Function

Composition parts

Controls air-fuel ratio of air-fuel

mixture to become theoretical air-

fuel ratio (about 14.7), which is

when

the

3-way

catalytic

converter's cleaning performance

is best. It also controls optimum

fuel supply based on coolant

temperature, driving conditions

etc.

Catalytic

converter

Decrease of CO, HC and NOx

It facilitates oxidation of CO and

HC and reduction of NOx so that

all 3 component gases are

cleaned simultaneously.

Monolith catalyst

HC

trap

catalytic

converter

<California>

HC decrease

During cold operation of engine,

exhaust

HC

is

temporarily

absorbed. And then Exhaust HC is

released

when

temperature

reaches to level at which catalyst

is activated. This allows HC to be

reduced.

Monolith catalyst

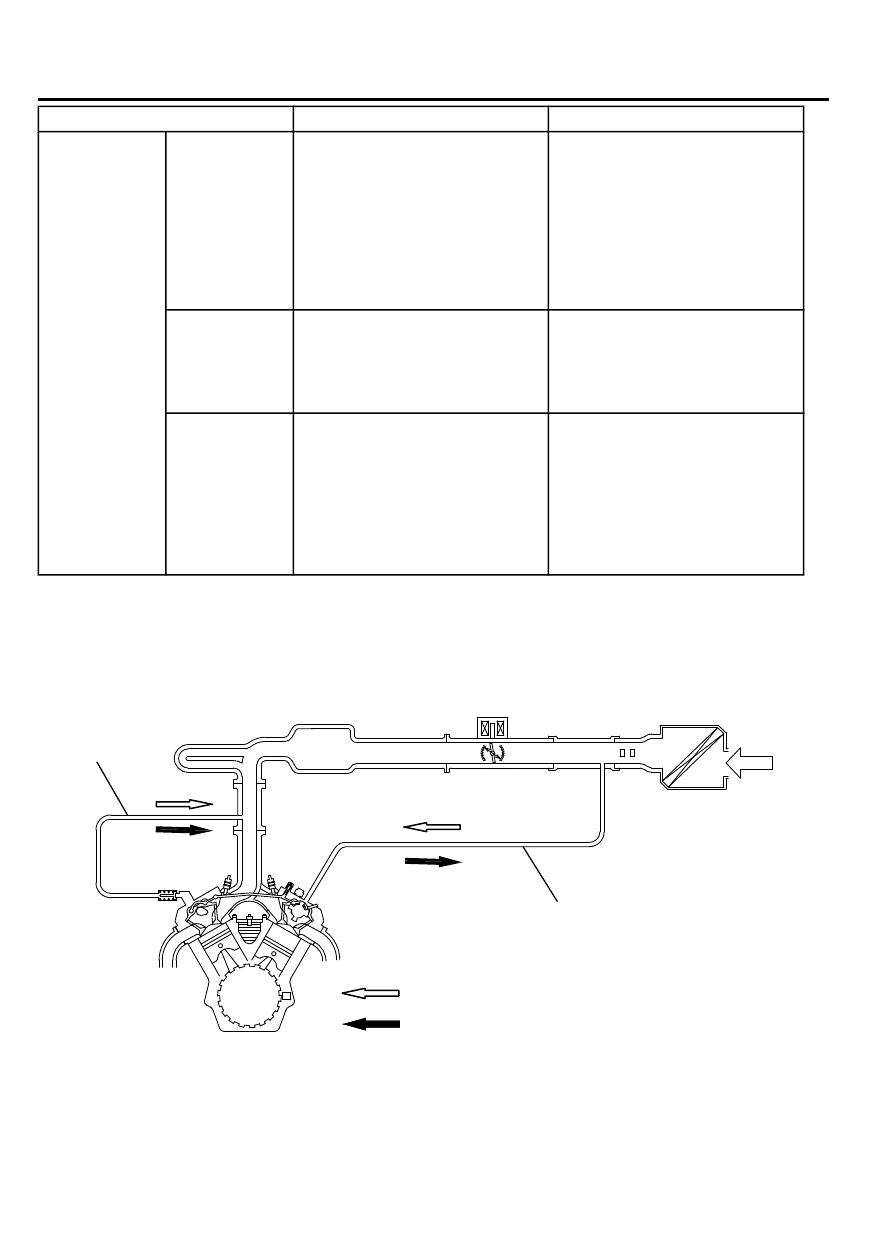

CRANKCASE VENTILATION SYSTEM

M21701000004USA0000010000

ZK602752 AA00

Ventilation hose

Breather hose

Air cleaner

PCV valve

Flow of blow-by gas and clean air (low load area)

Flow of blow-by gas (high load area)

17c-4

EMISSION CONTROL

CRANKCASE VENTILATION SYSTEM