Content .. 1229 1230 1231 1232 ..

Mitsubishi Outlander XL. Manual - part 1231

PASSIVE SAFETY

M20000000320USA0000010000

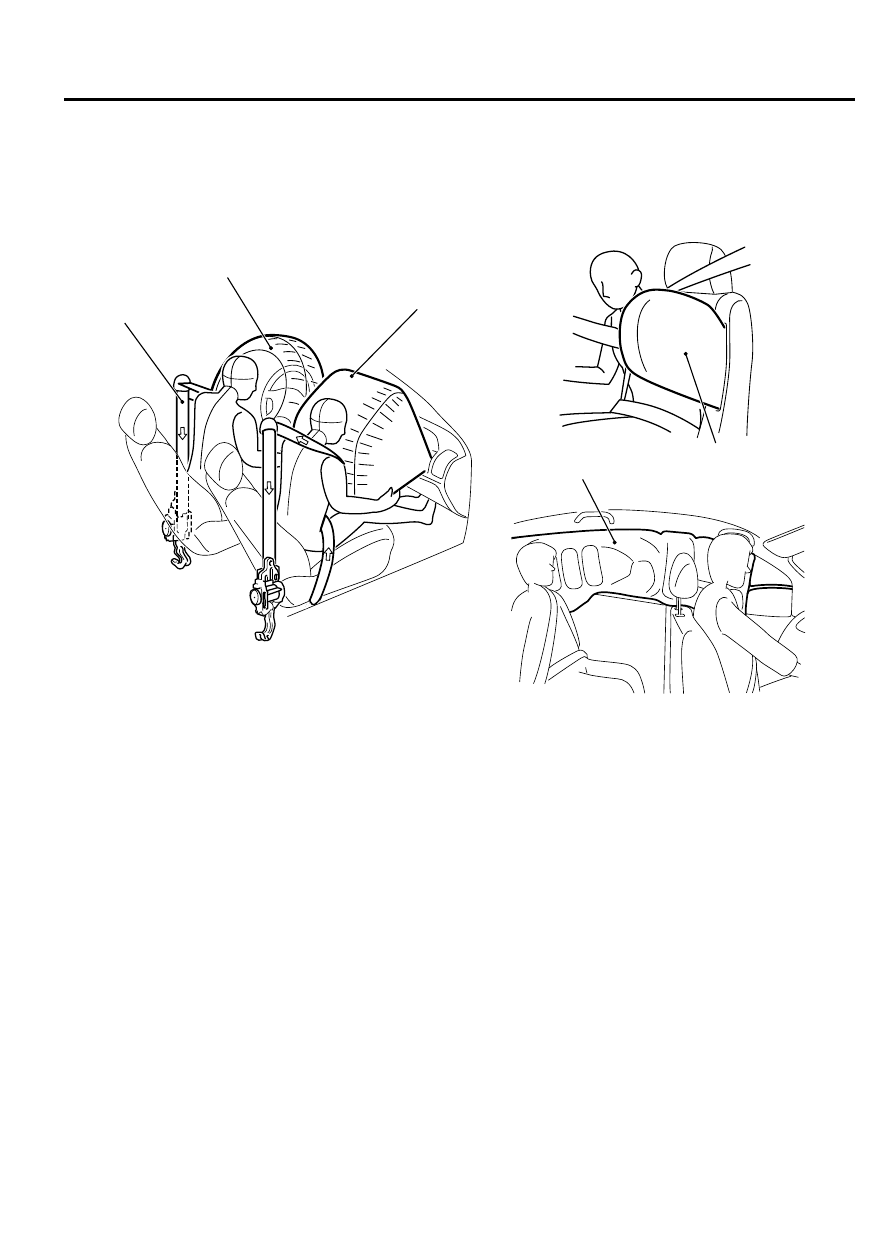

SRS AIR BAGS

ZC600850

Driver's air bag

module

Passenger's (front)

air bag module

Side-airbag module

Curtain air bag module

Seat belt with

pre-tensioner

0000

Dual Supplemental Restraint System (SRS) front air

bags deploy only upon detection of frontal impact.

When used in combination with the 3-point ELR seat

belts, they significantly reduce head and upper torso

injury to front-seat occupants.

The seat belts with pre-tensioner work simultaneously

with the SRS. The pre-tensioner takes up seat slack

immediately when a collision takes place by

restraining the front passengers sooner than the SRS.

This prevents the passengers from moving forward.

SIDE-AIRBAGS AND CURTAIN AIR BAGS

During a side collision, the SRS side-airbags

embedded in the front seat side area soften blows to

the front passenger's chest area, and the SRS curtain

air bags integrated into the roof side area soften blows

to the front/rear passenger's head area.

FRONT SEAT BELT

A seat belt with double pre-tensioner for shoulder and

lap has been installed on the driver's seat. A seat belt

with pre-tensioner is on the front passenger's seat.

This retracts the belt to eliminate slack, and increases

the initial restraint for passengers to limit movement

of the passenger, increasing safety. In addition, the

variable force limiter has been installed on the seat

belts (driver's/front passenger's seats) to properly

absorb the load on a passenger by extending the belt

if the belt tension exceeds a certain level, increasing

safety against an accident with a collision.

GENERAL

00-7

TECHNICAL FEATURES