Mitsubishi Outlander GS45X. Manual - part 981

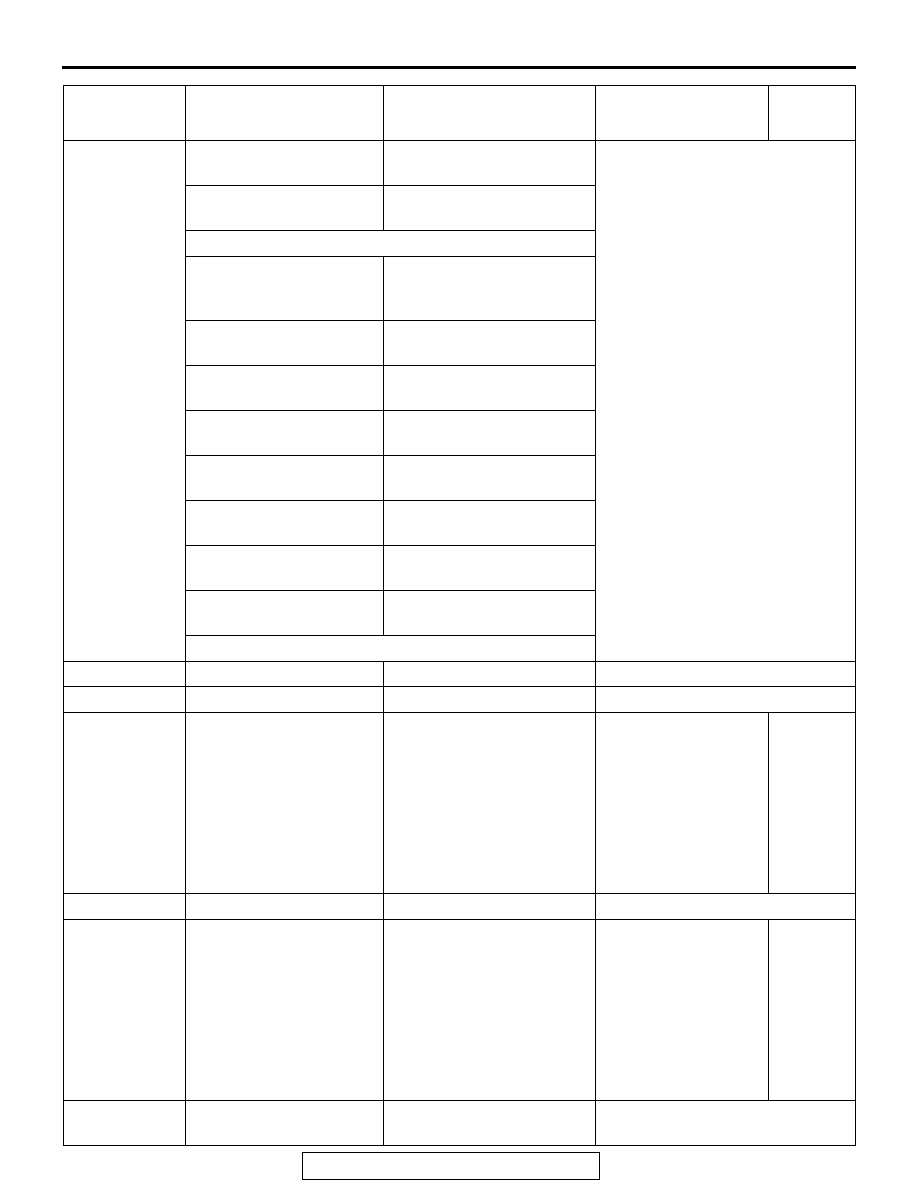

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L ENGINE>

13B-857

41

Oxygen sensor heater

monitoring

HTR_ENA: YES

−

EGR and/or VVT system

monitoring

EGR_ENA: YES

Completion status of

non-continuous monitors

this monitoring cycle:

Completion status of

non-continuous monitors

this monitoring cycle:

Catalyst monitoring

completed

CAT_CMPL: YES or NO

Heated catalyst

monitoring completed

HCATCMPL: YES

Evaporative system

monitoring completed

EVAPCMPL: YES or NO

Secondary air system

monitoring completed

AIR_CMPL: YES

Oxygen sensor

monitoring completed

O2S_CMPL: YES or NO

Oxygen sensor heater

monitoring completed

HTR_CMPL: YES or NO

EGR and/or VVT system

monitoring completed

EGR_CMPL: YES or NO

42

Control module voltage

VPWR: xx.xx V

See M.U.T.-III item No. 1.

43

Absolute Load Value

LOAD_ABS: xxxxx.x %

See M.U.T.-III item No. 72.

44

Fuel/Air Commanded

Equivalence Ratio

LAMBDA: xxx.xxx

Engine: running

• "1" means

"stoichiometric

air fuel ratio".

The smaller air

fuel ratio, the rich

return. The more

air fuel ratio, the

lean return.

0

− 1.999

(Display

range)

45

Relative Throttle Position TP_R: xxx.x%

See M.U.T.-III item No. BC.

46

Ambient air temperature

AAT: xxx

°C (xxx°F)

• Ignition

switch:

"ON"

• Engine is

cold state

The value

displayed

approxima

tely

matches

the

ambient

temperatu

re

47

Absolute Throttle Position

B

TP_B: xxx.x%

See M.U.T.-III item No. BD.

PARAMETER

IDENTIFICATION

(PID)

DESCRIPTION

COMMON EXAMPLE OF

GENERAL SCAN TOOL

DISPLAY

INSPECTION

CONDITION

NORMAL

CONDITION