Mitsubishi Outlander GS45X. Manual - part 959

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L ENGINE>

13B-769

STEP 4. Using scan tool MB991958, check actuator test.

(1) Turn the ignition switch to the "ON" position.

(2) Check the following items in the actuator test. Refer to

Actuator Test Reference Table

.

a. Item 9: Fuel Pump.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the actuator operating properly?

YES : Go to Step 5.

NO : Repair or Replace. Then confirm that the malfunction

symptom is eliminated.

STEP 5. Check the ignition timing.

(1) Check the ignition timing at cranking.

Standard value: 5

° BTDC ± 3°

Q: Is the ignition timing normal?

YES : Go to Step 6.

NO : Check for installed conditions of the timing belt. Then

confirm that the malfunction symptom is eliminated.

STEP 6. Check the fuel pressure.

Refer to On-vehicle Service

− Fuel Pressure Test

Q: Is the fuel pressure normal?

YES : Go to Step 7.

NO : Check the following items, and repair or replace the

defective items.

• Insufficient fuel pump discharge.

• Fuel pump filter clogged.

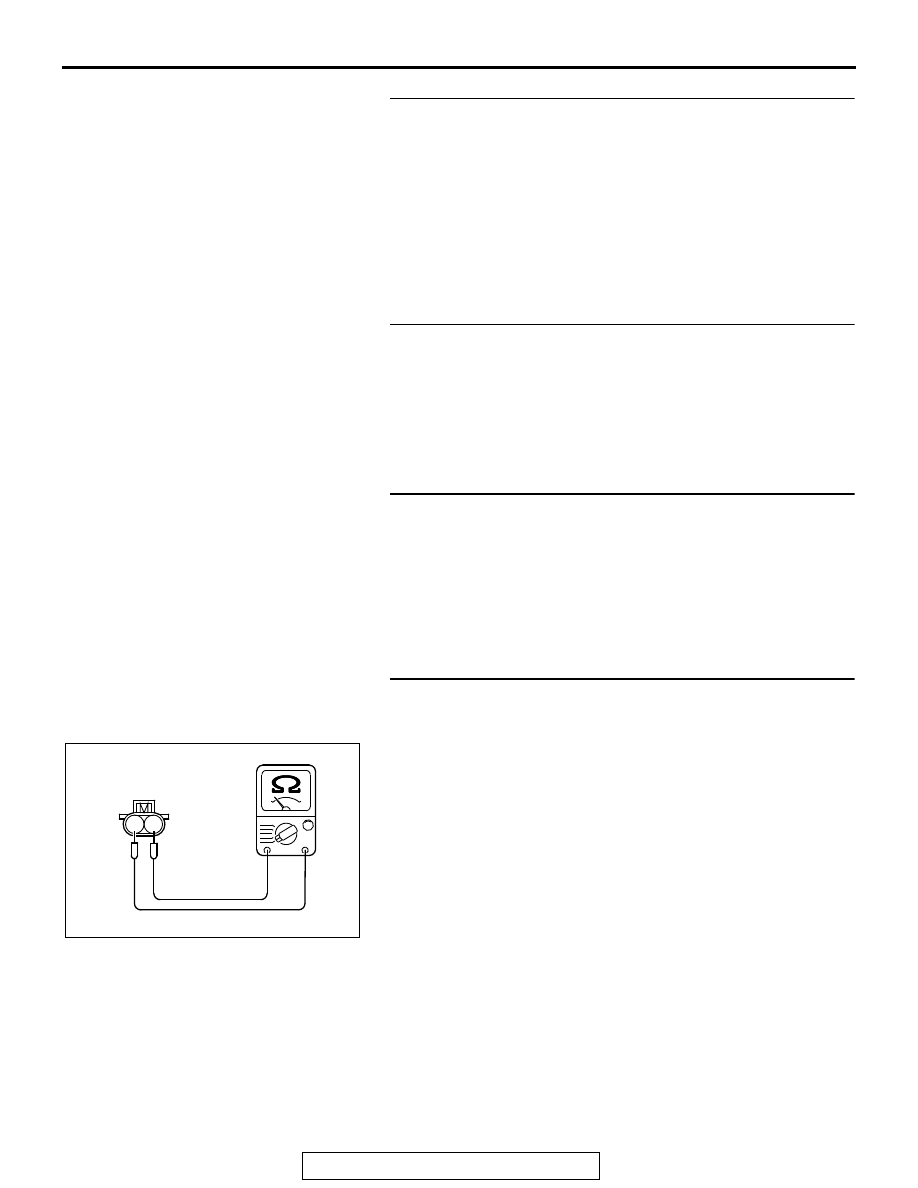

STEP 7. Check the left bank injector resistance.

(1) Disconnect the left bank injector connector B-115, B-116,

B-120.

(2) Measure the resistance between each injector side

connector terminal No. 1 and No. 2.

Standard value: 10.5

− 13.5 Ω [at 20°C (68°F)]

Q: Is the measured resistance between 10.5 and 13.5 ohms

[at 20

°C (68°F)]?

YES : Go to Step 8.

NO : Replace the faulty injector. Then confirm that the

malfunction symptom is eliminated.

AK700204

1 2

AB

Injector side

connector