Mitsubishi Outlander GS45X. Manual - part 885

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L ENGINE>

13B-473

DTC SET CONDITIONS

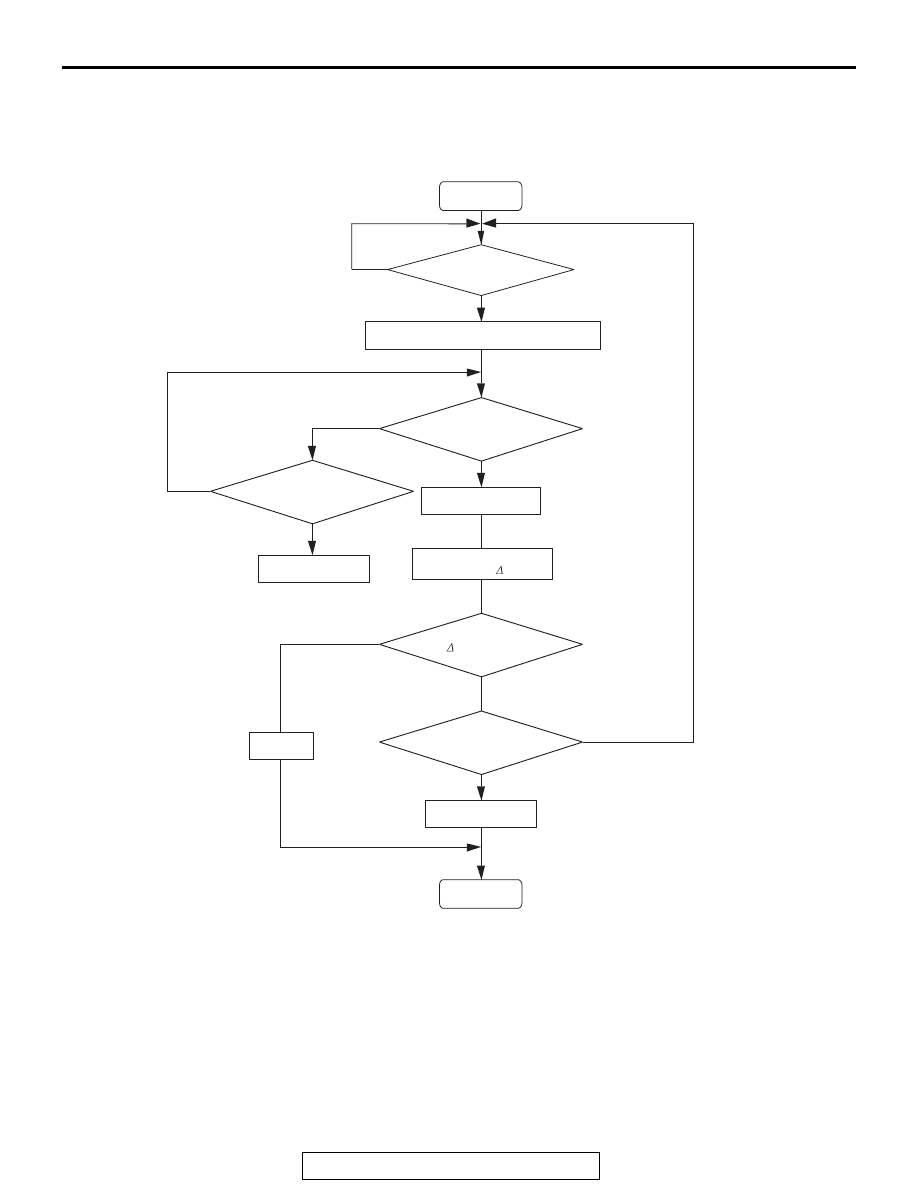

Logic Flow Chart (Monitor Sequence)

.

Check Conditions

• Amount of remaining fuel is 15 − 40 percent of

capacity when the engine is started.

• Engine coolant temperature is less than 36°C

(97

°F) when the engine is started.

• Intake air temperature is less than 36°C (97°F)

when the engine is started.

• Engine coolant temperature is more than 60°C

(140

°F).

• Intake air temperature is more than −10°C (14°F).

• Fuel temperature is less than 36°C (97°F).

• Power steering pressure switch: "OFF"

• When the evaporative emission purge solenoid

and evaporative emission ventilation solenoid are

closed, the change of the pressure in the fuel

tank is less than 451 Pa (0.13 in.Hg).

• The pressure fluctuation is less than 647 Pa (0.19

in.Hg).

AK604523

Start

Yes

No

Monitoring

conditions?

Depressurize fuel tank pressure

Yes

Yes

No

No

Gross leak

monitoring conditions

Shut purge line

Specified times

have passed

Malfunction

(Gross leak)

Measure reverting

pressure: PFT

Yes

Yes

No

No

PFT > PT

Specified times

monitored

Malfunction

End

Good

AB