Mitsubishi Outlander GS45X. Manual - part 873

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L ENGINE>

13B-425

• Barometric pressure is higher than 76 kPa (22.4

in.Hg).

• The engine load is with in the positive torque

load.

• Adaptive learning is complete for the vane which

generates a crankshaft position signal.

• While the engine is running, excluding sudden

acceleration/deceleration and fuel shut-off opera-

tion.

Judgement Criterion (change in the angular

acceleration of the crankshaft is used for mis-

fire detection).

• Misfire has occurred more frequently than

allowed during the last 200 revolutions [when the

catalyst temperature is higher than 1,000

°C

(1,832

°F)].

or

• The occurrence rate of engine misfiring within the

1,000 engine revolutions is more than 1.7 %

<Except for California> or 1.8 % <California>.

.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function

− OBD-II Drive Cycle −

.

.

TROUBLESHOOTING HINTS (The most

likely causes for this code to be set are:)

• Spark plug failed.

• Ignition system related part(s) failed.

• Low compression pressure.

• ECM failed.

DIAGNOSIS

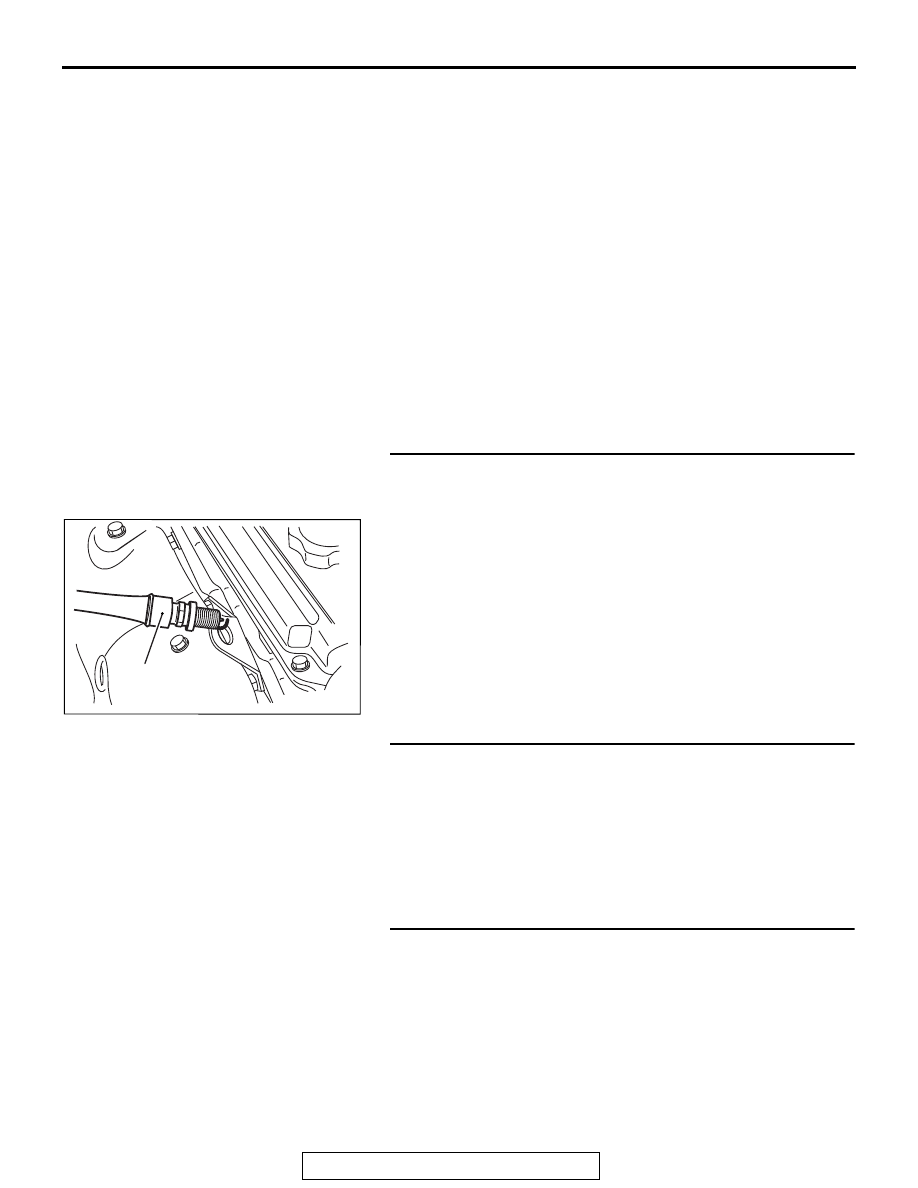

STEP 1. Check the No. 5 cylinder ignition coil spark.

(1) Remove the intake manifold.

(2) Remove the No. 5 cylinder ignition coil.

(3) Remove the No. 5 cylinder spark plug and connect to the

ignition coil.

(4) Ground the spark plug side electrode securely.

• When the engine is cranked, the spark plug should

spark.

Q: Did it spark?

YES : Go to Step 3.

NO : Go to Step 2.

STEP 2. Check the No. 5 cylinder spark plugs.

Refer to GROUP 16, Ignition System

− On-vehicle Service −

Spark Plug Check And Cleaning

.

Q: Is the spark plug normal?

YES : Refer to INSPECTION PROCEDURE 24

− Ignition

Circuit System

.

NO : Replace the No. 5 cylinder spark plug. Then go to

Step 5.

STEP 3. Check the compression.

Refer to GROUP 11C, On-vehicle Service

− Compression

Pressure Check

Q: Are there any abnormalities?

YES : Replace it. Then go to Step 5.

NO : Go to Step 4.

AK700310AB

Spark plug