Mitsubishi Outlander GS45X. Manual - part 600

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-223

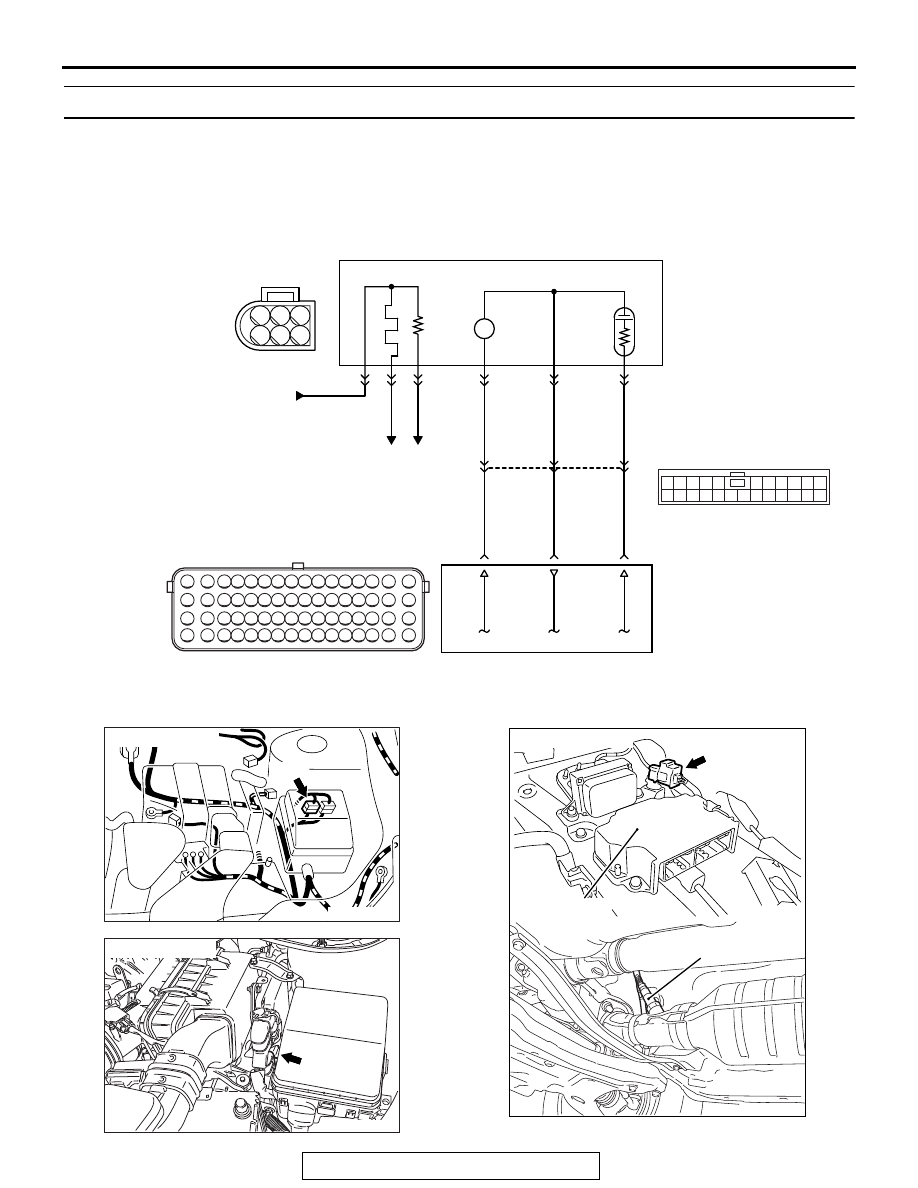

DTC P0131: Linear Air-Fuel Ratio Sensor Circuit Low Voltage

1

2

3 4 5 6 7 8 9 10 11 12 13 14 15 16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

P

3

2

1

6

5

4

AKA00449

1

12 13 14 15 16 1718 19 20 2122 2324

2 3 4 5

6 7 8 9 10 11

LINEAR AIR-FUEL RATIO SENSOR CIRCUIT

LINEAR

AIR-FUEL

RATIO

SENSOR

FROM

MFI RELAY

WHITE

BLA

CK

RED

WHITE

BLA

CK

RED

C-142

ENGINE

CONTROL

MODULE

38

39

56

4

5

1

14

20

21

2

6

3

B-10

A-12

AC

TO ECM TO ECM

AKA00842 AB

Connector: A-12

A-12

AK704090AB

Connector: B-10

B-10 (GR)

AK704089AD

Linear air-fuel

ratio sensor

SRS-ECU

Connector: C-142

C-142 (B)