Mitsubishi Outlander GS45X. Manual - part 546

SERVICE SPECIFICATIONS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-7

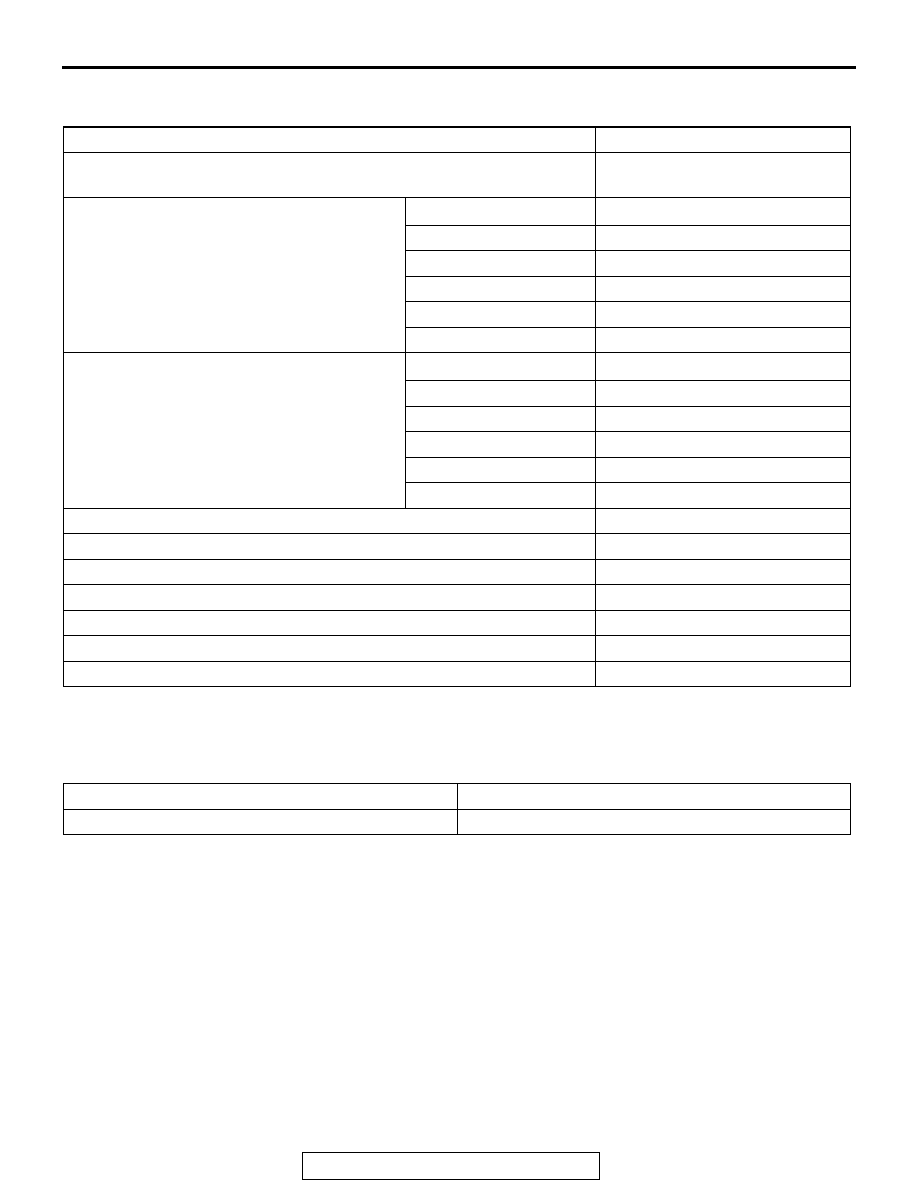

SERVICE SPECIFICATIONS

M1131000303113

SEALANT AND ADHESIVE

M1131000501456

ITEMS

STANDARD VALUE

Fuel pressure kPa (psi)

Approximately 324 (47) at curb

idle

Intake air temperature sensor resistance k

Ω −20°C (−4°F)

13

− 17

0

°C (32°F)

5.3

− 6.7

20

°C (68°F)

2.3

− 3.0

40

°C (104°F)

1.0

− 1.5

60

°C (140°F)

0.56

− 0.76

80

°C (176°F)

0.30

− 0.45

Engine coolant temperature sensor

resistance k

Ω

−20°C (−4°F)

14

− 17

0

°C (32°F)

5.1

− 6.5

20

°C (68°F)

2.1

− 2.7

40

°C (104°F)

0.9

− 1.3

60

°C (140°F)

0.48

− 0.68

80

°C (176°F)

0.26

− 0.36

Heated oxygen sensor output voltage V

0.6

− 1.0

Linear air-fuel ratio sensor heater resistance

Ω

2.3

− 4.2 [at 20°C (68°F)]

Heated oxygen sensor heater resistance

Ω

4.5

− 8.0 [at 20°C (68°F)]

Injector coil resistance

Ω

10.5

− 13.5 [at 20°C (68°F)]

Throttle actuator control motor coil resistance

Ω

0.3

− 80 [at 20°C (68°F)]

Intake engine oil control valve coil resistance

Ω

6.9

− 7.9 [at 20°C (68°F)]

Exhaust engine oil control valve coil resistance

Ω

6.9

− 7.9 [at 20°C (68°F)]

ITEM

SPECIFIED SEALANT

Engine coolant temperature sensor threaded portion LOCTITE 262 or equivalent