Mitsubishi Outlander GS45X. Manual - part 482

CYLINDER HEAD GASKET

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-59

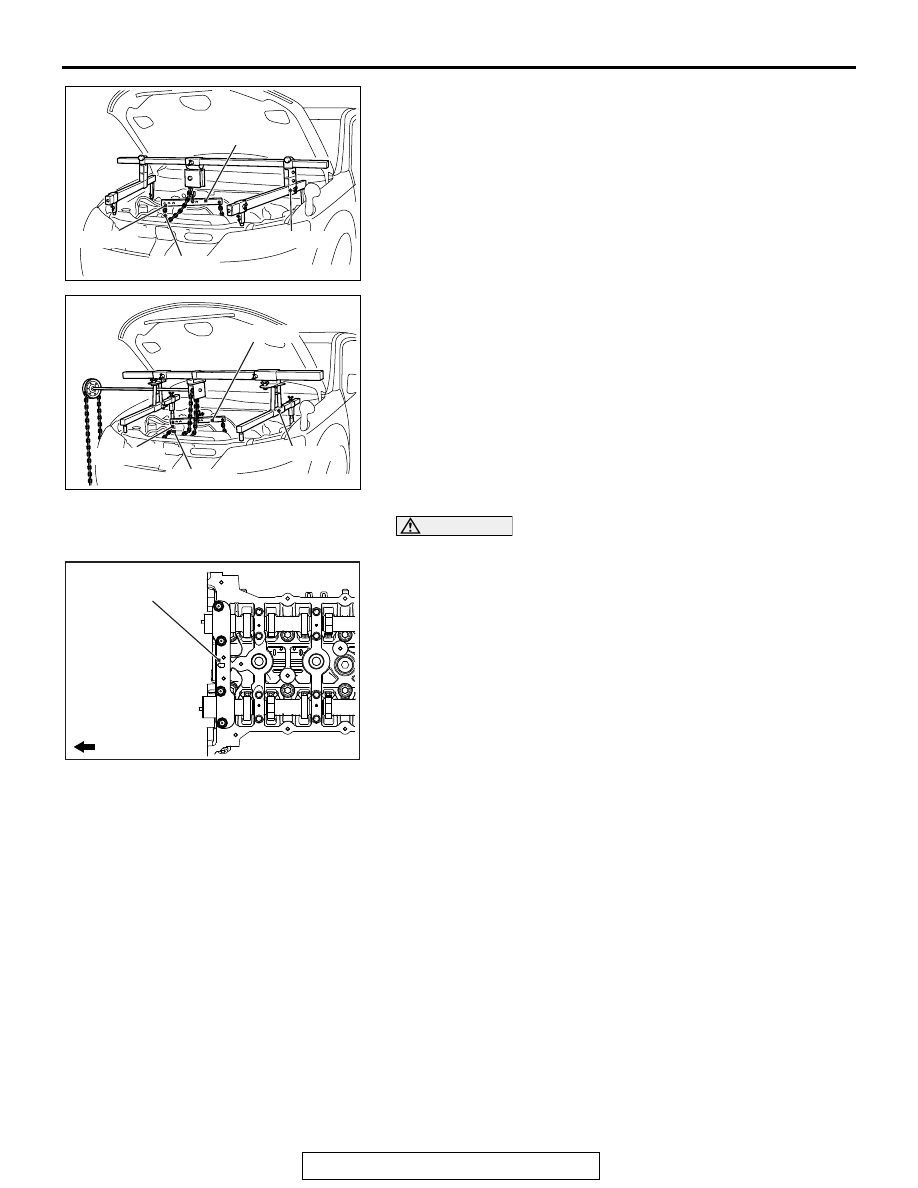

3. Remove special tool engine hanger (MB991928 or

MB991895) which was installed for supporting the engine

and transaxle assembly when the valve timing chain was

removed.

CAUTION

Be careful not to drop the camshaft bearing.

4. Loosen the mounting bolts of front camshaft bearing cap in

the order of number shown in the figure, and remove the

front camshaft bearing cap assembly.

.

AC506487

AE

MB991527

MB991454

MB991928

MB991956

AC506484

MB991527

AE

MB991454

MB991956

MB991895

AC506745

AD

1

2

3

4

Engine front

Front camshaft

bearing cap

assembly