Mitsubishi Outlander GS45X. Manual - part 367

ABS DIAGNOSIS

TSB Revision

ANTI-LOCK BRAKING SYSTEM (ABS)

35B-89

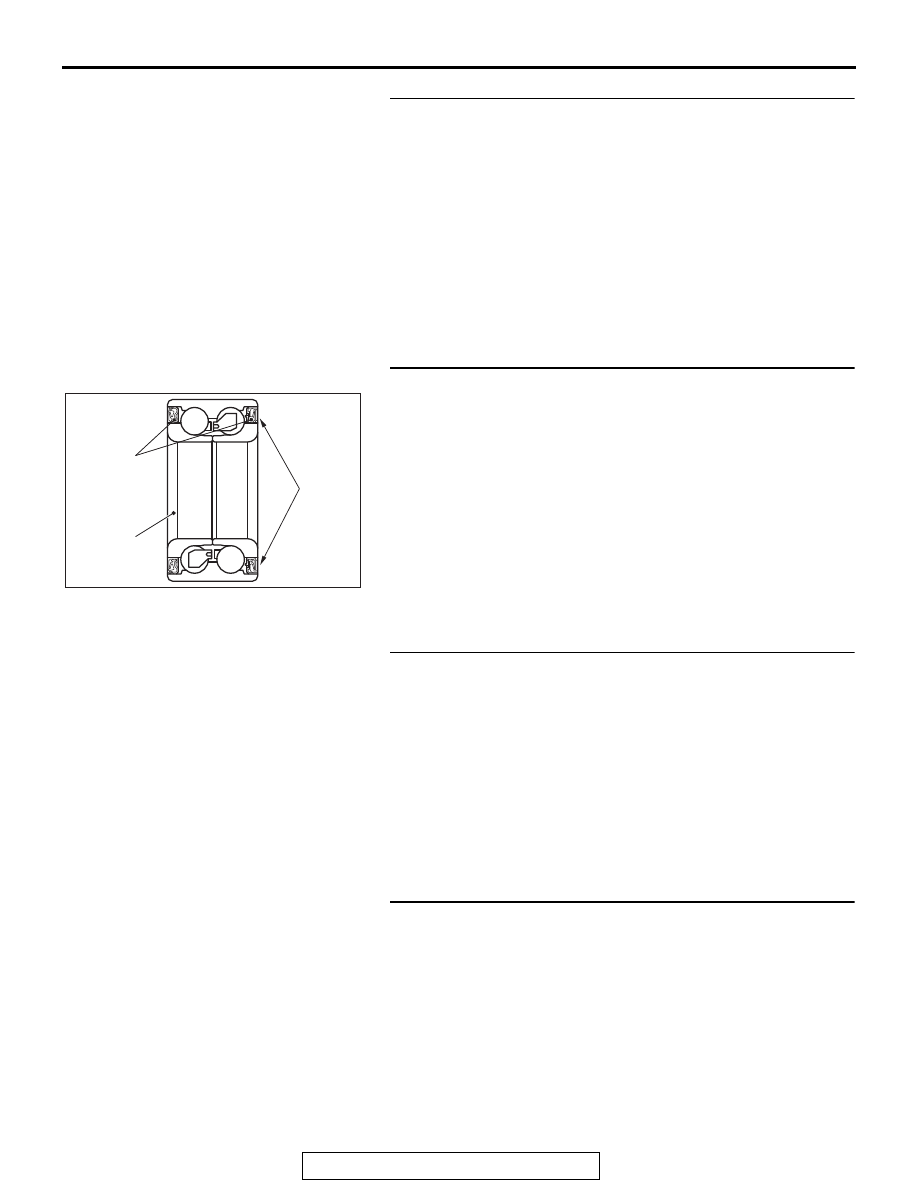

STEP 9. Check for wheel bearing looseness

NOTE:

.

•

Loose wheel bearing may increase the gap between the

wheel speed sensor <FL> and the wheel speed detection

magnet encoder.

•

Check the wheel bearing <FL> for looseness (Refer to

GROUP 26

−

Wheel Bearing Play Check

Q: Is the check result normal?

YES : Go to Step 10.

NO : Replace the wheel bearing <FL> (Refer to GROUP 26

− Front Axle Hub Assembly

). Then go to Step

13.

STEP 10. Check wheel speed detection encoder

Check the encoder for adhesion of foreign materials or defor-

mation.

Q: Is the check result normal?

YES : Go to Step 11.

NO (Adhesion of foreign materials) : Remove the foreign

materials and clean the encoder so as not to disturb

the magnetization pattern on it while taking care of the

magnet, magnetic substance, and magnetic

attraction. Then go to Step 13.

NO (Deformation) : Replace the wheel bearing <FL>

(Refer to GROUP 26

− Front Axle Hub Assembly

). Then go to Step 13.

STEP 11. Check whether the DTC is reset.

(1) Erase the DTC.

(2) Drive the vehicle at 12mph (20 km/h) or higher.

NOTE: The ABS warning light does not turn OFF in some

cases unless the vehicle runs at 12mph (20 km/h) or higher.

Q: Is DTC C1046 set?

YES : Replace the wheel speed sensor <FL> (Refer to

). Then go to Step 12.

NO : Intermittent malfunction (Refer to GROUP 00

− How

to Use Troubleshooting/How to Cope with Intermittent

Malfunctions

).

STEP 12. Check whether the DTC is reset.

(1) Erase the DTC.

(2) Drive the vehicle at 12mph (20 km/h) or higher.

NOTE: The ABS warning light does not turn OFF in some

cases unless the vehicle runs at 12mph (20 km/h) or higher.

Q: Is DTC C1046 set?

YES : Replace the hydraulic unit (integrated with ABS-ECU)

(Refer to

). Then go to Step 13.

NO : The procedure is complete.

AC608761

Oil seal

Magnetic

encoder

Wheel

bearing

AB