Content .. 1559 1560 1561 1562 ..

Mitsubishi Outlander GS45X. Manual - part 1561

POWER STEERING DIAGNOSIS

TSB Revision

POWER STEERING

37-7

STEP 2. Check the drive belt for damage.

Q: Is the drive belt damaged?

YES : Replace the drive belt (Refer to GROUP 11A

−

Crankshaft pulley

<2.4L>, GROUP 11C

−

Crankshaft pulley

<3.0L>). Then go to Step

10.

NO : Go to Step 3.

STEP 3. Check the fluid level.

(1) Park the vehicle on a flat, level surface, and then start the

engine.

(2) Turn the steering wheel several times to raise the

temperature of the fluid to approximately 50

− 60°C (122 −

140

°F).

(3) With the engine running, turn the wheel all the way to the

left and right several times.

(4) Check the fluid in the oil reservoir for foaming or milkiness.

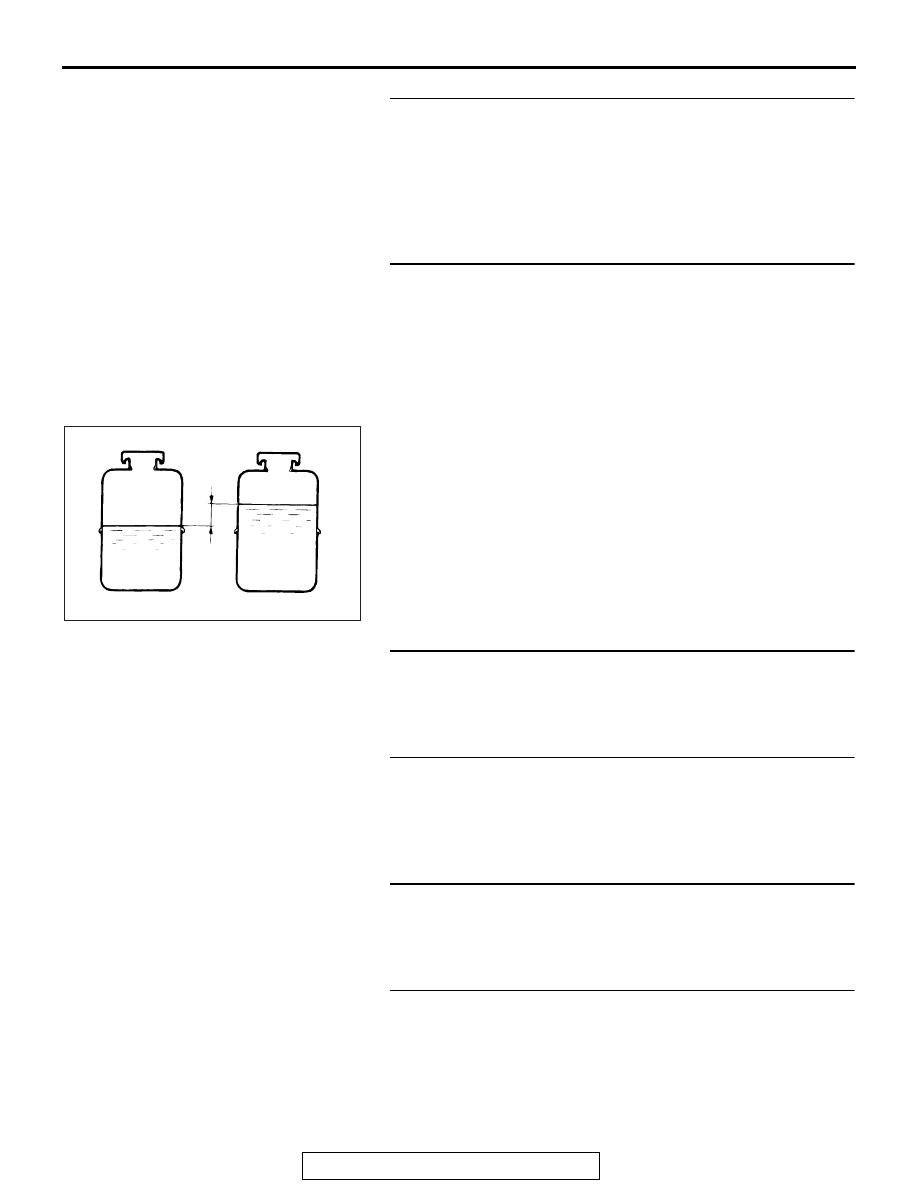

Check the difference of the fluid level when the engine is

stopped, and while it is running. If the change of the fluid

level is 5 mm (0.2 inch) or more, bleed the air from the

system. (Refer to

Q: Is the fluid foamy?

YES : Go to Step 4.

NO : Go to Step 10.

STEP 4. Check for entry of air.

Q: Has air entered?

YES : Bleed the air (Refer to

). Then go to Step 10 .

NO : Go to Step 5.

STEP 5. Check each hose for crushing or twisting.

Q: Is any hose crushed or twisted?

YES : Replace the hose (Refer to

). Then go to Step

10 .

NO : Go to Step 6.

STEP 6. Check for oil leaks.

Q: Are there oil leaks?

YES : Repair it. Then go to Step 10.

NO : Go to Step 7.

STEP 7. Check the wheel alignment (camber and caster).

Refer to GROUP 33, On-vehicle Service

− Front Wheel Align-

ment Check and Adjustment

Q: Is the alignment incorrect?

YES : Adjust it (Refer to

NO : Go to Step 8.

AC608306

With engine stopped

AC

Fluid level change: Within 5 mm (0.2 in)

With engine running