Content .. 1322 1323 1324 1325 ..

Mitsubishi Outlander GS45X. Manual - part 1324

DIAGNOSIS

TSB Revision

ELECTRONIC CONTROL AWD

27C-19

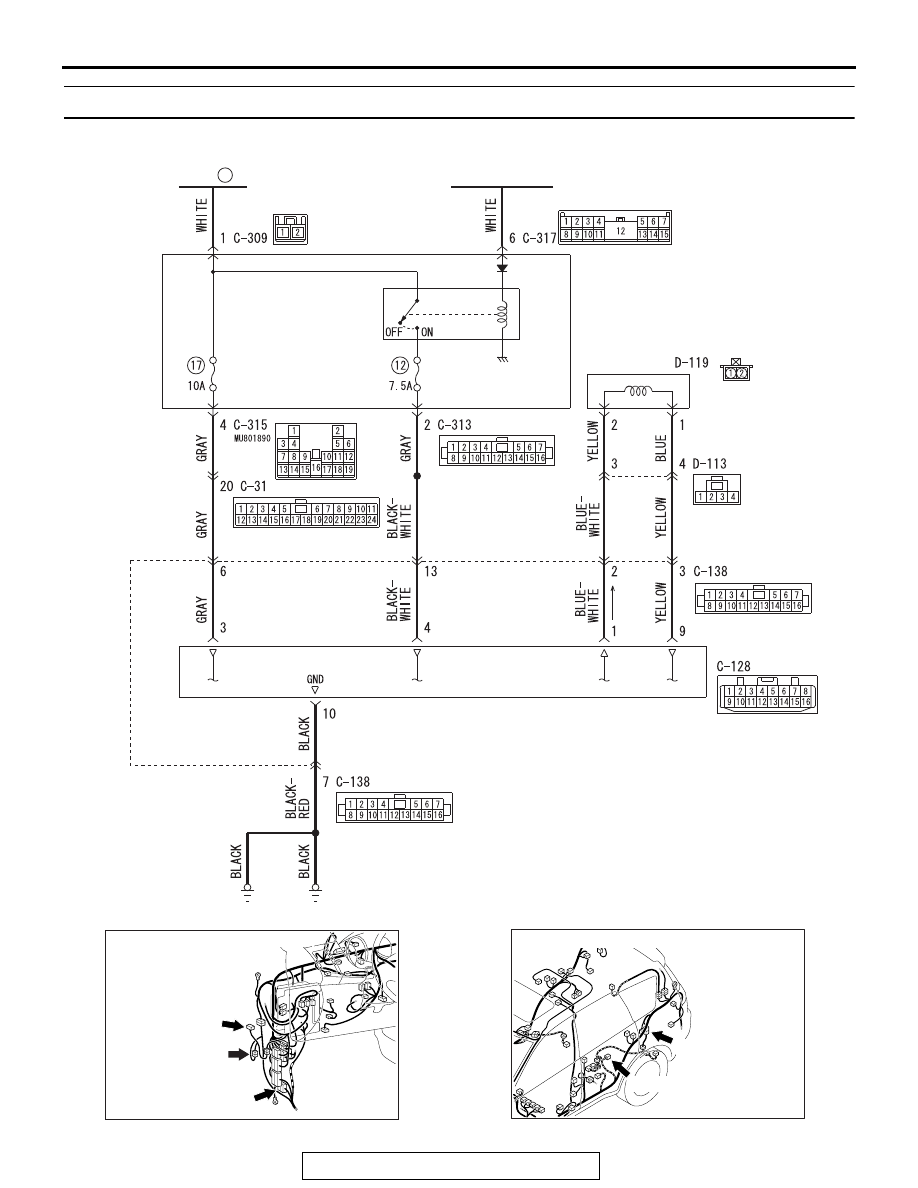

DTC C145A: Wiring harness and coupling coil short circuit failure

ELECTRONIC

CONTROL

COUPLING

SOLENOID

ETACS-ECU

FUSIBLE

LINK

34

IGNITION

SWITCH (IG1)

IG1

RELAY

AWD-ECU

ACA02787

AC901227AB

C-128

C-31

C-138

Connectors: C-31, C-128, C-138

AC901229AB

Connectors: D-113, D119

D-113

D-119