Content .. 1236 1237 1238 1239 ..

Mitsubishi Outlander GS45X. Manual - part 1238

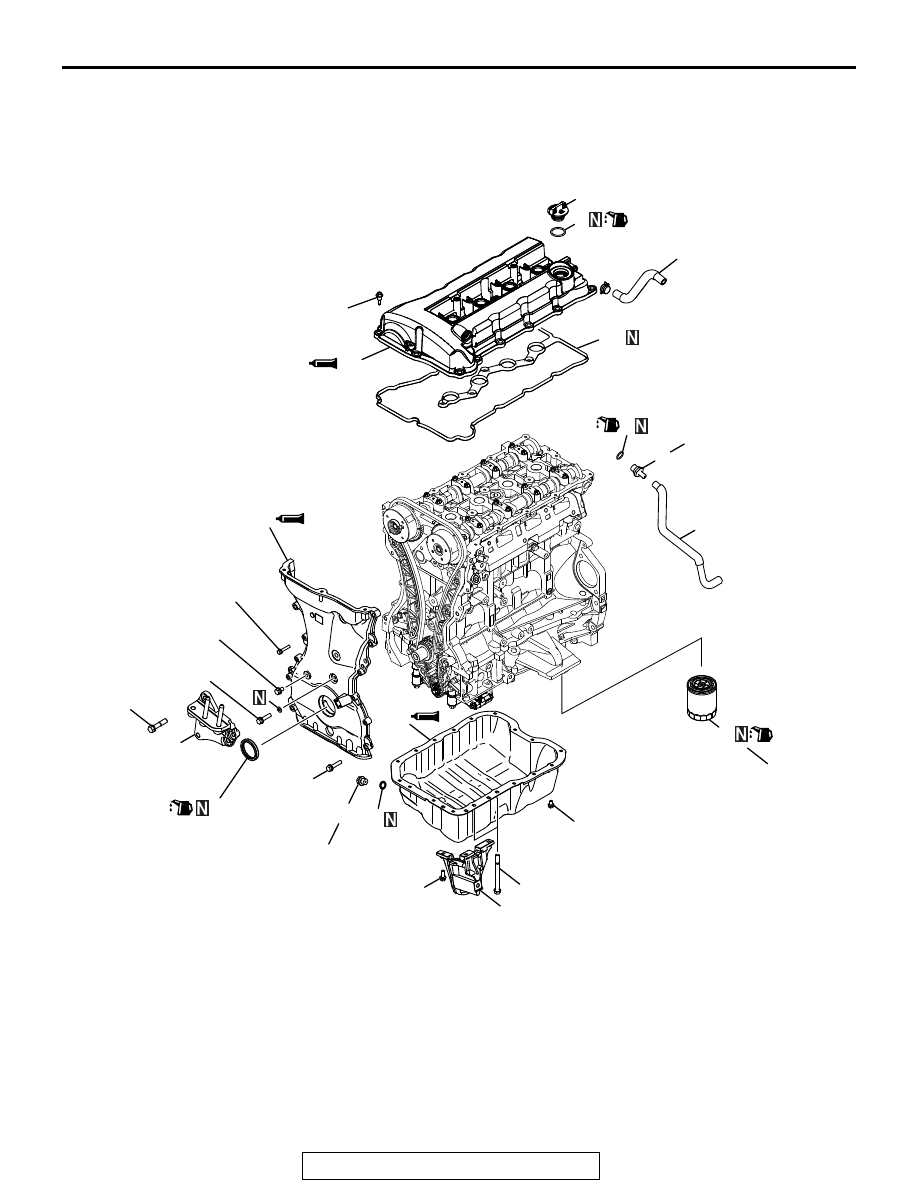

OIL PAN AND TIMING CHAIN CASE

TSB Revision

ENGINE OVERHAUL <2.4L ENGINE>

11B-27

OIL PAN AND TIMING CHAIN CASE

REMOVAL AND INSTALLATION

M1113026301166

AKA00438 AB

1

2

3

4

5

6

2.5 ± 0.4 N·m

22 ± 3 in-lb

11

10

3.0 ± 1.0 N·m

27 ± 8 in-lb

48 ± 5 N·m

35 ± 4 ft-lb

15

24 ± 4 N·m

18 ± 2 ft-lb

8

7

39 ± 5 N·m

29 ± 3 ft-lb

29 ± 2 N·m

21 ± 1 ft-lb

12

10 ± 2 N·m

89 ± 17 in-lb

13

13 ± 1 N·m

115 ± 8 in-lb

14

16

23 ± 6 N·m

17 ± 4 ft-lb

9

10 ± 2 N·m

89 ± 17 in-lb

10 ± 2 N·m

89 ± 17 in-lb

→ 5.5 ± 0.5 N·m

49 ± 4 in-lb

14 ± 2 N·m

124 ± 17 in-lb

Removal steps

1. Breather hose

2. PCV hose

3. Positive Crankcase Ventilation

Valve

4. Positive Crankcase Ventilation

Valve gasket

5. Oil filler cap

6. O-ring

7. Oil drain plug

8. Oil drain plug gasket

<<A>> >>E<<

9. Oil filter

>>D<<

10.Cylinder head cover

11. Cylinder head cover gasket

12.Air compressor bracket

<<B>> >>C<<

13.Oil pan

14.Engine support bracket

>>B<<

15.Front oil seal

<<C>> >>A<<

16.Timing chain case

Removal steps (Continued)