Content .. 1231 1232 1233 1234 ..

Mitsubishi Outlander GS45X. Manual - part 1233

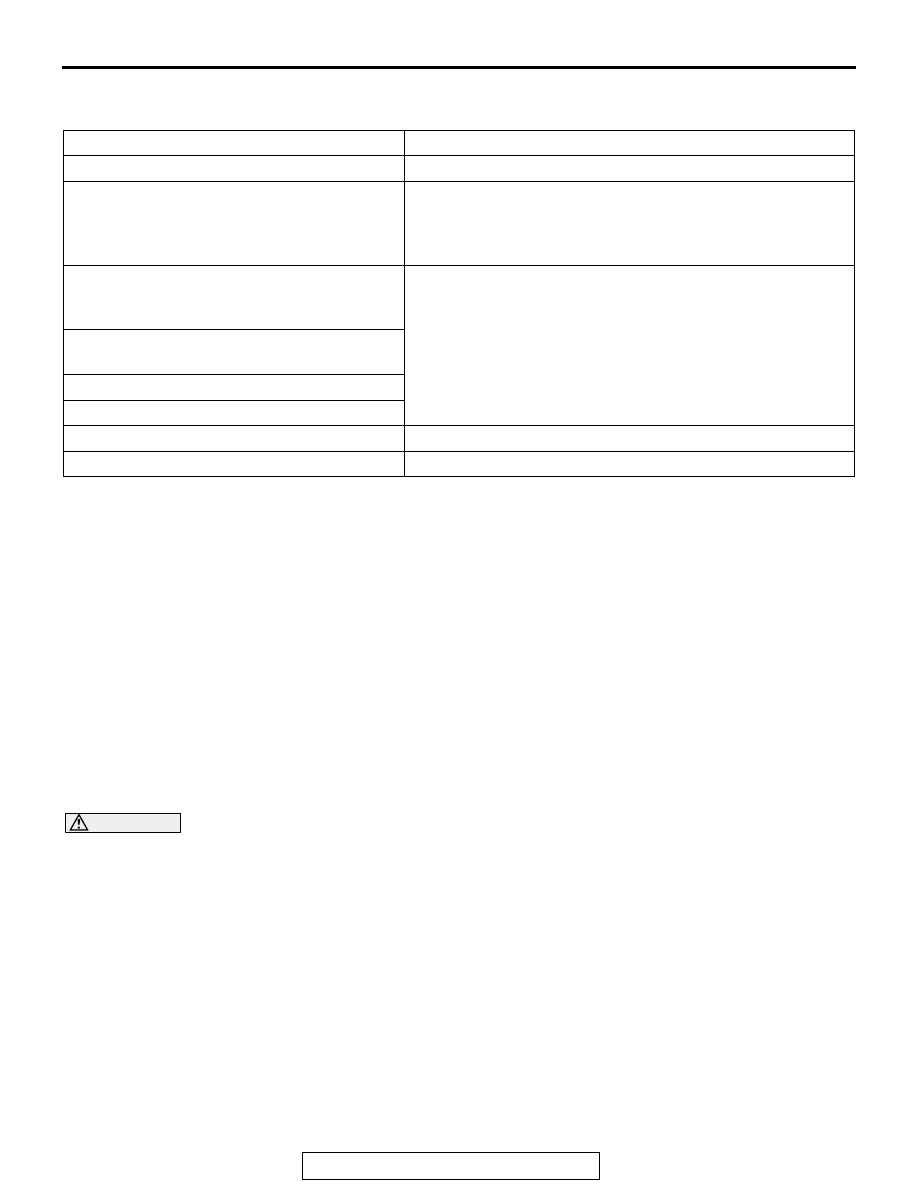

SEALANTS

TSB Revision

ENGINE OVERHAUL <2.4L ENGINE>

11B-7

SEALANTS

M1113000503092

NOTE: The number in square brackets shows the

genuine part number.

.

LIQUID GASKET (FIPG)

FIPG is used for some parts in the engine. It is nec-

essary to pay attention to an application amount,

application procedure and applied surface condition

for this gasket to fully achieve its purpose.

Too small amount causes leakage while too much

amount squeezes out to block or narrow water and

oil passages. Therefore, it is absolutely essential to

apply a correct amount of liquid sealant continuously

without break to eliminate leakage from joints.

FIPG used for engine parts hardens reacting with

moisture in the air, and is usually used for metal

flanges.

.

CAUTION

Reapply the FIPG with care to the followings.

1. Completely remove the old FIPG including the

residue in gaps of parts.

2. Using Mitsubishi genuine parts cleaner

(MZ100387) or equivalent, degrease the FIPG

application surface carefully.

3. According to the FIPG application proce-

dures, apply it accurately.

.

DISASSEMBLY

Parts assembled with FIPG can be easily disassem-

bled without using a special method. In some cases,

however, it is necessary to lightly tap parts with a

wooden hammer or similar tool to break sealant

between mating surfaces. Or lightly driving a smooth

and thin gasket scraper in mating surfaces is useful,

but full care must be exercised not to damage mating

surfaces. As special tool oil pan FIPG cutter

(MD998727) is set, use this tool.

.

CLEANING OF GASKET SURFACE

Completely remove all deposits from the gasket sur-

face with a gasket scraper or wire brush. Make sure

that the surface to which FIPG is applied is smooth.

The gasket surface must be free from grease and

foreign substances. Be sure to remove old FIPG that

has entered mounting holes and screw holes.

.

APPLICATION PROCEDURE

Apply FIPG in a determined diameter and continu-

ously without break. Completely enclose the periph-

ery of mounting holes. FIPG can be wiped off if it is

not hardened. Install parts in place while FIPG is still

wet. Take care not to allow FIPG to adhere to other

locations than necessary locations during installa-

tion. Do not pour oil or water on applied locations or

do not start the engine until sufficient time (approxi-

mately one hour) passes. The application procedure

of FIPG may differ depending on areas. Follow the

procedure in the body of the manual to apply FIPG.

Points of application

Specified sealant / adhesive

Drive plate bolt

Three bond 1324 or equivalent

Oil pan

Three bond 1227D,

Three bond 1217G (Mitsubishi part No. 1000A923),

Three bond 1207F (Mitsubishi part No. 1000A992),

LOCTITE 5970, LOCTITE 5900

Cylinder head cover (matching area of the

cylinder head and the timing chain case

assembly)

Three bond 1227D,

Three bond 1217G (Mitsubishi part No. 1000A923),

LOCTITE 5900

Cylinder head gasket (matching area of the

cylinder block and the cylinder head)

Timing chain case

Ladder frame

Engine coolant temperature sensor

Three bond 1324N, LOCTITE 262

Engine oil pressure switch

Three bond 1141J, Three bond 1212D, Three bond 1215