Mitsubishi Outlander GS45X. Manual - part 64

REAR COMBINATION LIGHT

TSB Revision

CHASSIS ELECTRICAL

54A-253

STEP 8. Check ETACS-ECU connectors C-312 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is ETACS-ECU connectors C-312 in good condition?

YES : Go to Step 9.

NO : Repair the damaged parts.

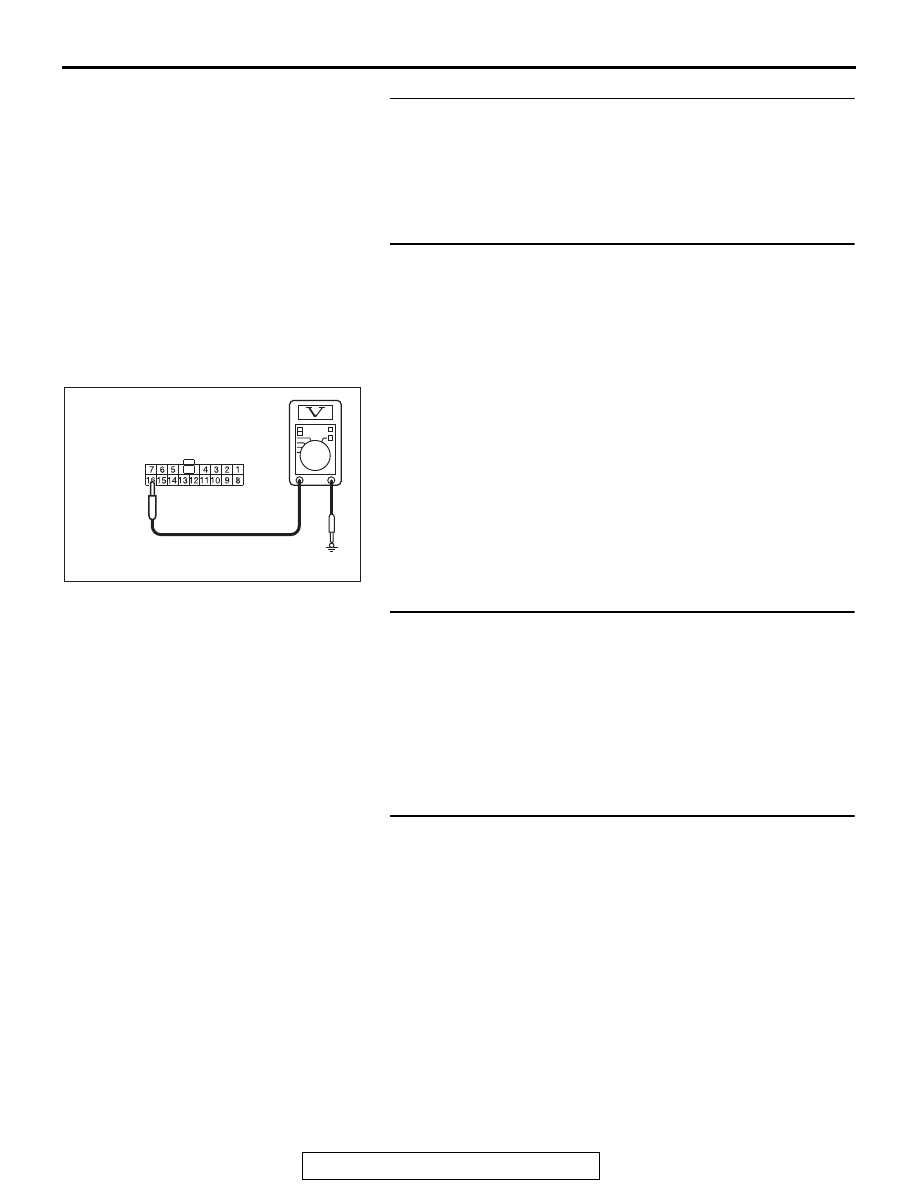

STEP 9. Check the battery power supply circuit to the

ETACS-ECU. Measure the voltage at ETACS-ECU

connector C-312.

(1) Disconnect connector measure the voltage available at the

wiring harness side of the connector.

(2) Disconnecting the ETACS-ECU connector C-312.

(3) Stoplight switch: ON

(4) Measure the voltage between ETACS-ECU connector

C-312 terminal No. 16 and the body ground.

• The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 11.

NO : Go to Step 10.

STEP 10. Check the wiring harness between ETACS-ECU

connector C-312 (terminal No. 16) and stoplight relay

connector C-133 (terminal No. 2).

• Check the signal line for short circuit.

Q: Is the wiring harness between ETACS-ECU connector

C-312 (terminal No. 16) and stoplight relay connector

C-133 (terminal No. 2) in good condition?

YES : Go to Step 11.

NO : Repair the wiring harness.

STEP 11. Check the wiring harness between stoplight relay

connector C-133 (terminal No. 4) and intermediate

connector C-131 (terminal No. 9).

Check the communication line for open or short circuit.

Q: Is the wiring harness between stoplight relay connector

C-133 (terminal No. 4) and intermediate connector C-131

(terminal No. 9) in good condition?

YES : Go to Step 12.

NO : Repair the wiring harness.

AC608254EX

Harness side: C-312