Mitsubishi Outlander (2013+). Manual - part 744

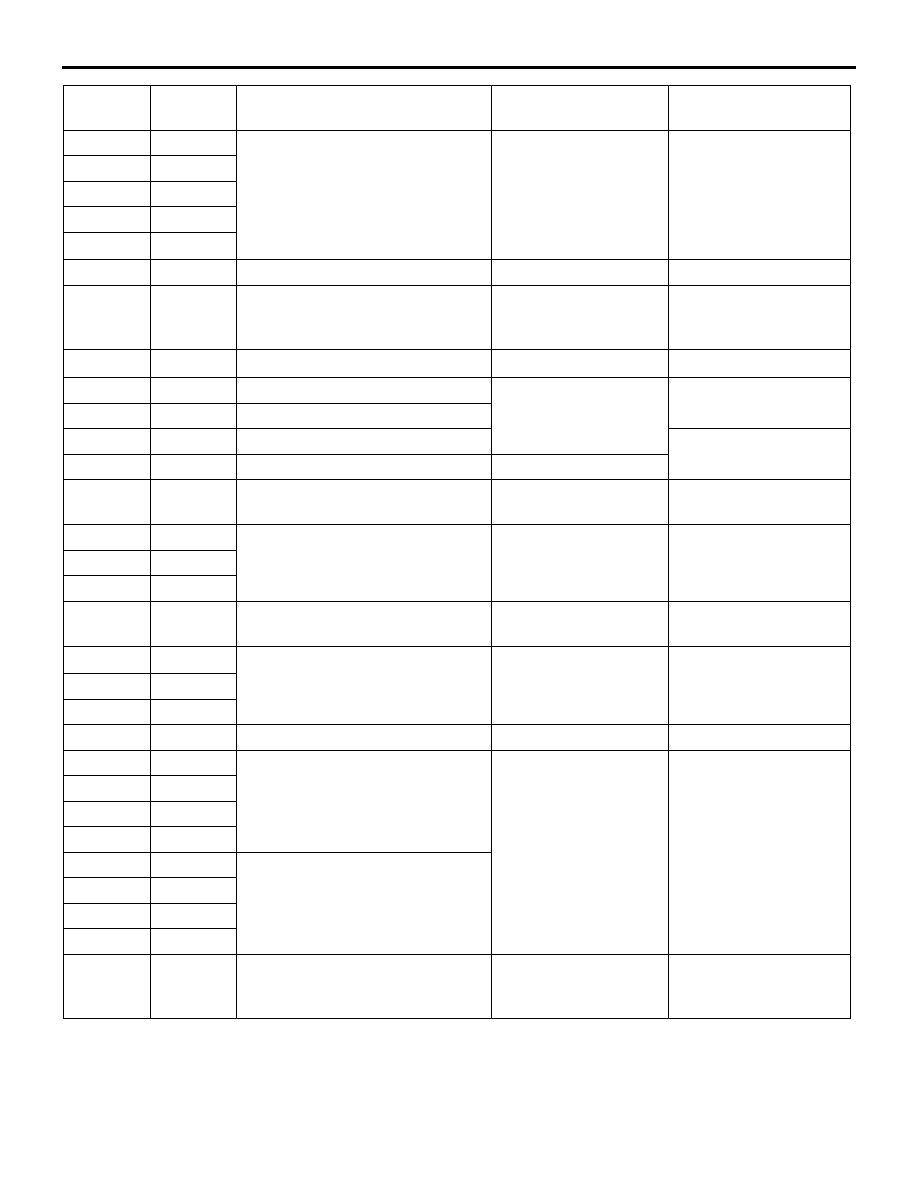

TROUBLESHOOTING

HEATER, AIR CONDITIONER AND VENTILATION

55-32

2

ILO-

−

−

−

3

HTR3

4

HTR2

5

HTR1

6

− 11

−

12

AC/P

A/C pressure sensor input

Refer to

Refer to

13

INC

Interior temperature sensor

Sensor probe

temperature: 25

°C (4.0

k

Ω)

2.1 to 2.7 V

14

− 16

−

−

−

−

17

SENG

Sensor earth

Always

1 V or less

18

E

Earth

19

B/UP

Battery power supply

System voltage

20

IG1

IG power supply

Ignition switch: ON

21

P/TC

Power transistor (DRAIN)

Air volume control dial:

Maximum air volume

0 to 2 V

22

ILL+

−

−

−

23

ILO+

24

ILL-

25

P/TB

Power transistor (GATE)

Air volume control dial:

Maximum air volume

System voltage

26

− 30

−

−

−

−

31

CANL

32

CANH

41

IG1

Motor power supply

Ignition switch: ON

System voltage

42

A/PB'

Air mixing damper control motor*

1

or Air mixing damper control

motor (RH)*

2

−

−

43

A/PA'

44

A/PB

45

A/PA

46

A/DB'

Air mixing damper control motor

(LH)*

2

47

A/DA'

48

A/DB

49

A/DA

50

+

Fin thermo sensor

Sensor probe

temperature: 25

°C (4.0

k

Ω)

2.1 to 2.7 V

Terminal

No.

Terminal

code

Check item

Check condition

Normal condition