Mitsubishi Outlander (2013+). Manual - part 665

BACK-UP LAMP

CHASSIS ELECTRICAL

54A-145

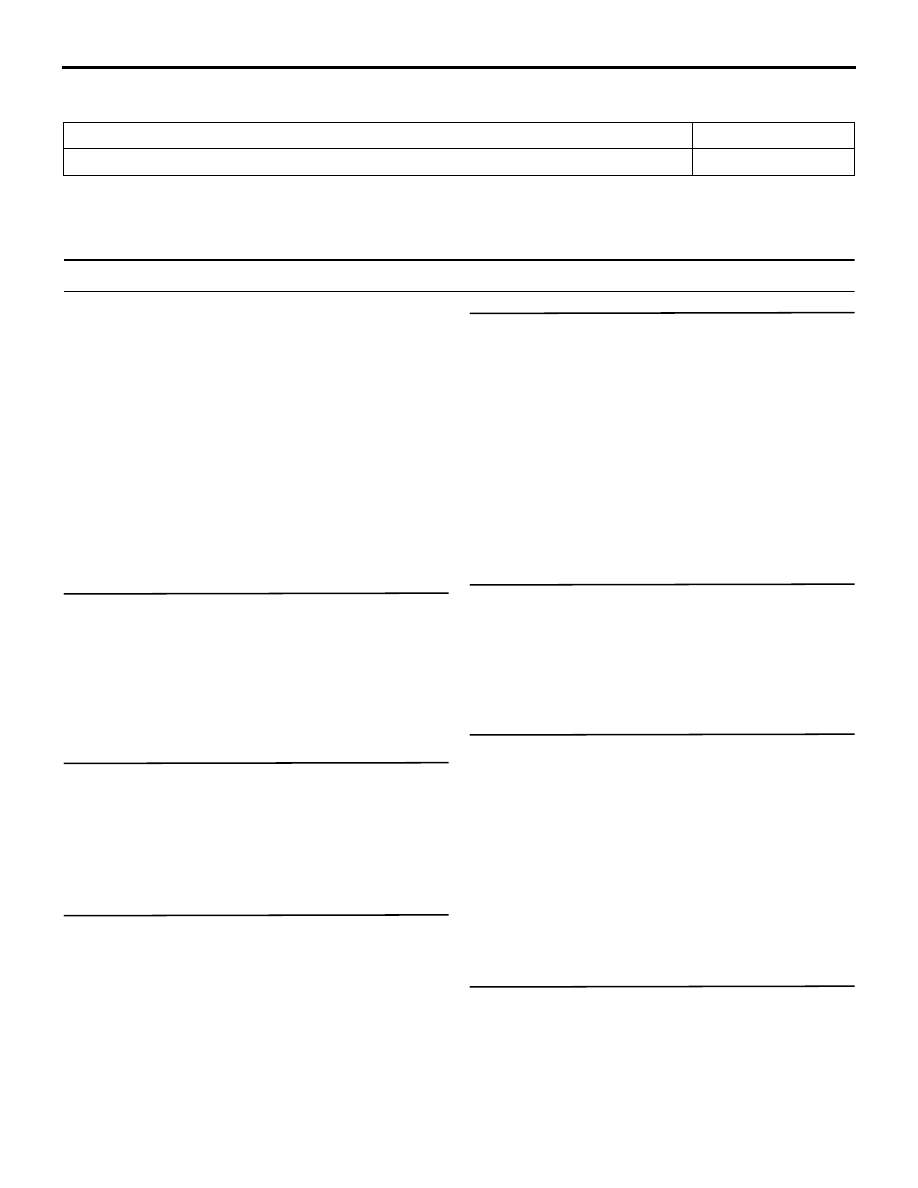

TROUBLE SYMPTOM CHART

M1542400500011

Trouble symptom

Reference page

The back-up lamps do not illuminate normally.

SYMPTOM PROCEDURES

The back-up lamps do not illuminate normally.

COMMENTS ON TROUBLE SYMPTOM

When the back-up lamp does not illuminate or extin-

guish normally, the power supply or the earth circuit

to the back-up lamp or the inhibitor switch may be

defective.

PROBABLE CAUSES

• Malfunction of the inhibitor switch

• Malfunction of bulbs

• Malfunction of the back-up lamp assembly

• Damaged harness wires and connectors

DIAGNOSIS PROCEDURE

STEP 1. Bulb check

Check the bulb(s) of the lamp that does not illumi-

nate.

Q: Is the check result normal?

YES :

Go to Step 2.

NO :

Replace the bulb(s) of the lamp that does

not illuminate.

STEP 2. M.U.T.-III diagnosis code

Check if diagnosis code is set to the ETACS-ECU.

Q: Is the diagnosis code set?

YES :

Troubleshoot the ETACS-ECU. Refer to

.

NO :

Go to Step 3.

STEP 3. Check the inhibitor switch.

Check the continuity of the inhibitor switch. (GROUP

23A

− On-vehicle Service, Inhibitor Switch Continuity

Check .)

Q: Is the check result normal?

YES :

Go to Step 4

NO :

Replace the inhibitor switch.

STEP 4. Voltage measurement at the inhibitor

switch connector (power supply terminal).

(1) Remove the inhibitor switch connector, and

measure at the junction block side.

(2) Move the ignition switch to the ON position.

(3) Measure the voltage between the inhibitor switch

connector (power supply terminal) and body

earth.

OK: System voltage

Q: Is the check result normal?

YES :

Go to Step 6

NO :

Go to Step 5

STEP 5. Check of open circuit in power supply

line between the inhibitor switch connector and

the fusible link.

Q: Is the check result normal?

YES :

Go to Step 6

NO :

Repair the connector(s) or wiring harness.

STEP 6. Resistance measurement at the back-up

lamp connector (earth terminal).

(1) Disconnect the connector, and measure at the

wiring harness side.

(2) Measure the resistance between the back-up

lamp connector (earth terminal) and the body

earth.

OK: Continuity exists (2

Ω or less)

Q: Is the check result normal?

YES :

Go to Step 8

NO :

Go to Step 7

STEP 7. Check of open circuit in earth line

between the back-up lamp connector and body

earth.

Q: Is the check result normal?

YES :

Go to Step 8

NO :

Repair the connector(s) or wiring harness.