Mitsubishi Outlander (2013+). Manual - part 477

TROUBLESHOOTING

ACTIVE STABILITY CONTROL SYSTEM (ASC)

35C-83

STEP 5. M.U.T.-III data list

Check the following data list (Refer to

•

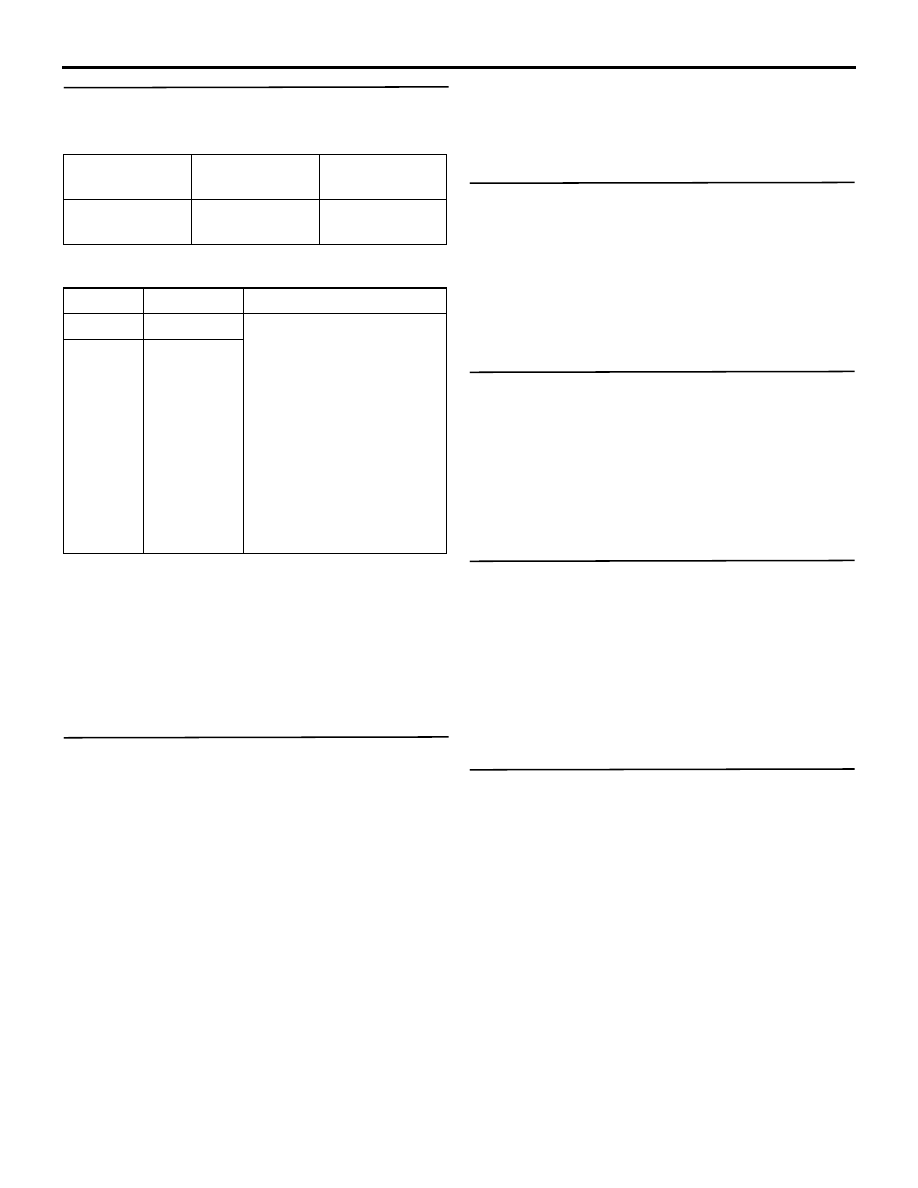

Item No.

Item name

Normal

condition

120

Parking brake

switch (Input)

ON

Pulled up parking brake lever.

•

Item No. Item name

Normal condition

70

Target gear

• "R"

• Selector lever:"R"

position

• "D"

• Selector lever:"D"

position

• "P"

• Selector lever:"P"

position

• "N"

• Selector lever:"N"

position

71

Actual gear

The selector lever is in the "R", "D", "N" and "P"

position. <Except M/T>

Q: Is the check result normal?

YES :

Go to Step 6.

NO <Item No. 120> :

Carry out the Inspection

procedure 3 "Brake warning lamp stays ON

with the parking brake lever released (ABS

warning lamp is OFF)" (Refer to

and then go to Step 10.

NO <Item No. 70, 71> :

Go to Step 9.

STEP 6. M.U.T.-III data list

Check the following data list under curb weight con-

dition or one occupant (driver) only in the vehicle, on

a flat road.(Refer to

• Item 09: G sensor

• Item 12: Yaw rate sensor

Q: Is the check result normal?

YES :

Go to Step 7.

NO :

Carry out the calibration of the G and yaw

rate sensor (Refer to

). Then go to

Step 9.

STEP 7. M.U.T.-III data list

Check the following data list (Refer to

• Item 10: Master cylinder pressure

Q: Is the check result normal?

YES :

Go to Step 8.

NO :

Carry out the calibration of the brake fluid

pressure sensor (Refer to

go to Step 10.

STEP 8. M.U.T.-III diagnosis code

Use M.U.T.-III to check that the diagnosis code is set

in the CVT-ECU.

Q: Is the diagnosis code set?

YES :

Carry out the diagnosis for the diagnosis

code (Refer to GROUP - 23A

−

Troubleshooting/Diagnosis Code Chart ).

NO :

Go to Step 9.

STEP 9. Retest the system.

Check if the HSA works with one occupant (driver)

only in the vehicle.

Q: Is the check result normal?

YES :

Intermittent malfunction (Refer to GROUP

00

− How to Use Troubleshooting/How to

Cope with Intermittent Malfunctions ).

NO :

Replace the hydraulic unit (integrated with

ASC-ECU) (Refer to

).

STEP 10. Retest the system.

Check if the HSA works with one occupant (driver)

only in the vehicle.

Q: Is the check result normal?

YES :

This diagnosis is complete.

NO :

Return to Step 1.