Mitsubishi Outlander (2013+). Manual - part 43

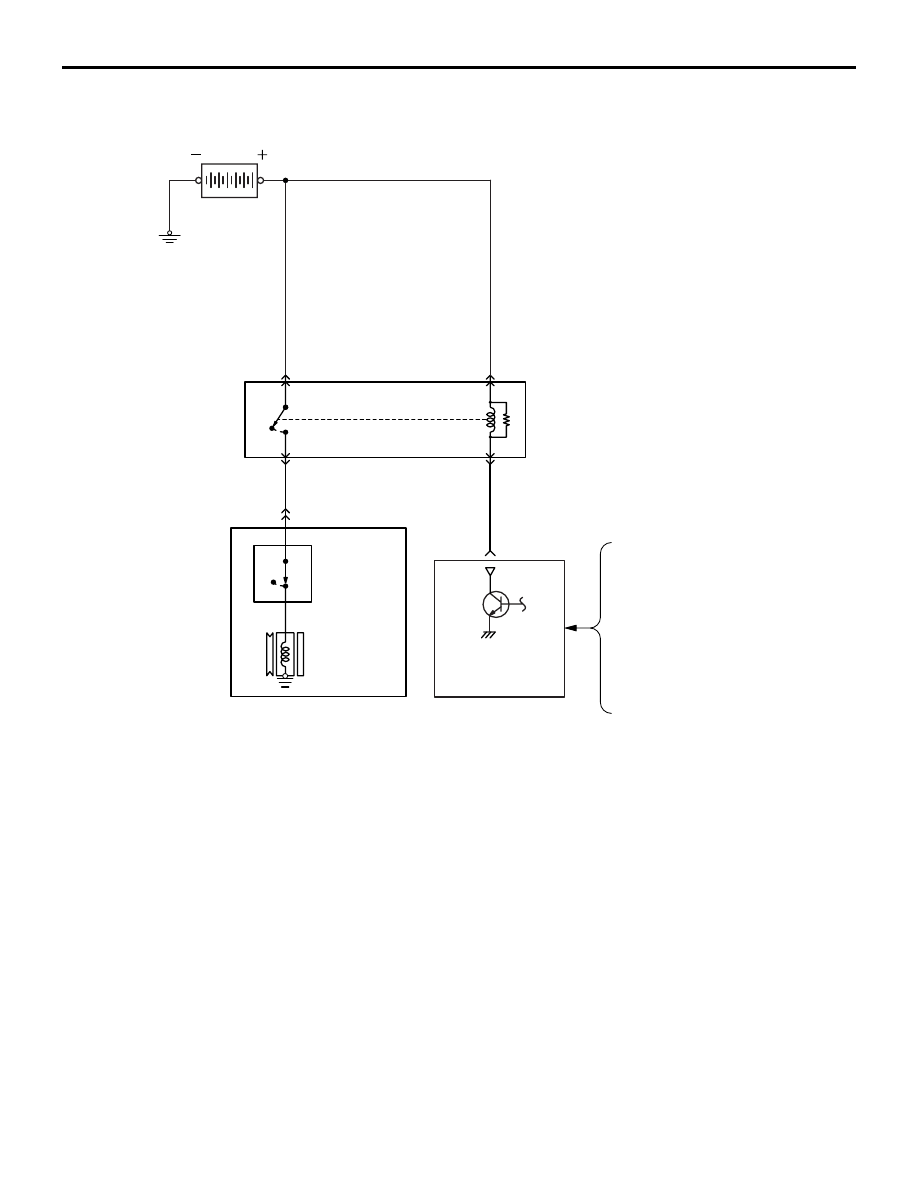

A/C COMPRESSOR RELAY CONTROL

MULTIPOINT FUEL INJECTION (MPI)

13A-40

A/C COMPRESSOR RELAY CONTROL

M2132034500722

After the A/C switch is turned ON and A/C compres-

sor relay reaches a state where it can turn ON,

engine-ECU turns ON the A/C compressor relay and

drives the A/C compressor. In order to prevent

change in engine speed due to increased load of

driving the compressor, it controls the A/C compres-

sor relay to drive the A/C compressor after idle-up is

complete. Also, in order to secure acceleration per-

formance, it turns OFF the A/C compressor relay for

a fixed amount of time, if the throttle opening angle

increases beyond a prescribed limit.

AK800141

OFF

ON

AH

Battery

A/C compressor relay

A/C compressor

assembly

A/C compressor

relay control

A/C compressor

clutch

A/C

refrigerant

temperature

switch

OFF

ON

Engine-ECU

A/C switch (CAN)

Crank angle sensor

Accelerator pedal position sensor

Vehicle speed signal (CAN)

Inhibitor switch (CAN)