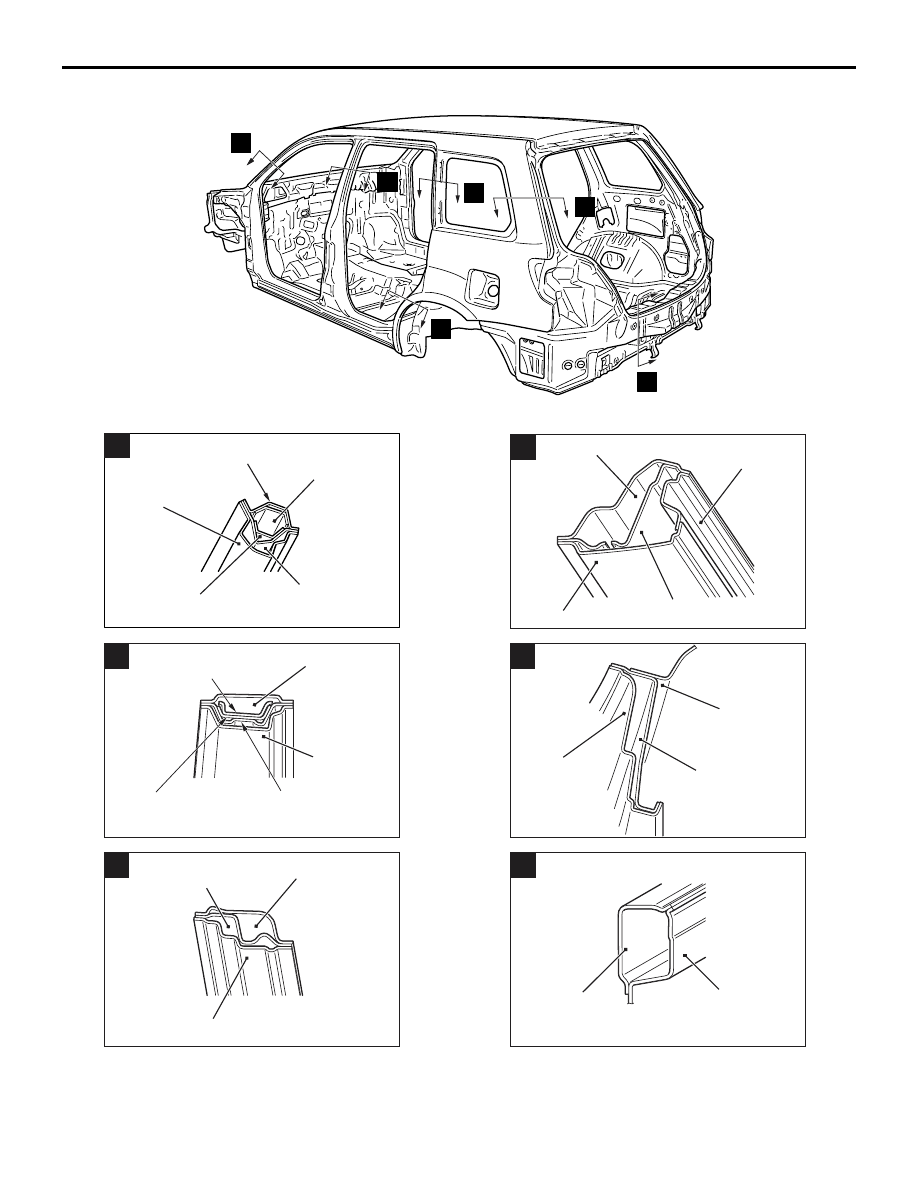

Mitsubishi Outlander. Body repair manual - part 4

AB200010

AB

G

H

I

J

K

L

AB200022

Front pillar

inner upper

reinforcement

Side outer

panel

Front pillar

support

Front pillar

inner upper

Front pillar upper

reinforcement

G

AB

AB100028AH

Centre pillar

inner panel

Centre pillar

reinforcement

H

Centre pillar

seat belt reinforcement

Rear door

hinge reinforcement

Side outer

panel

AB200195

I

Side outer panel

AB

Rear pillar

reinforcement upper

Quarter inner panel

AB100032AJ

Quarter outer

extension upper

Side outer panel

Quarter inner panel

J

Gate pillar

reinforcement

AB100029AF

Side outer

panel

Quarter inner

extension front

Rear wheel

house inner

panel

K

AB100260AF

Rear end

crossmember

inner

Rear end

crossmember

outer

L

BODY MAIN CROSS-SECTIONAL VIEWS

BODY CONSTRUCTION

1-5