Mitsubishi Outlander (2003+). Manual - part 291

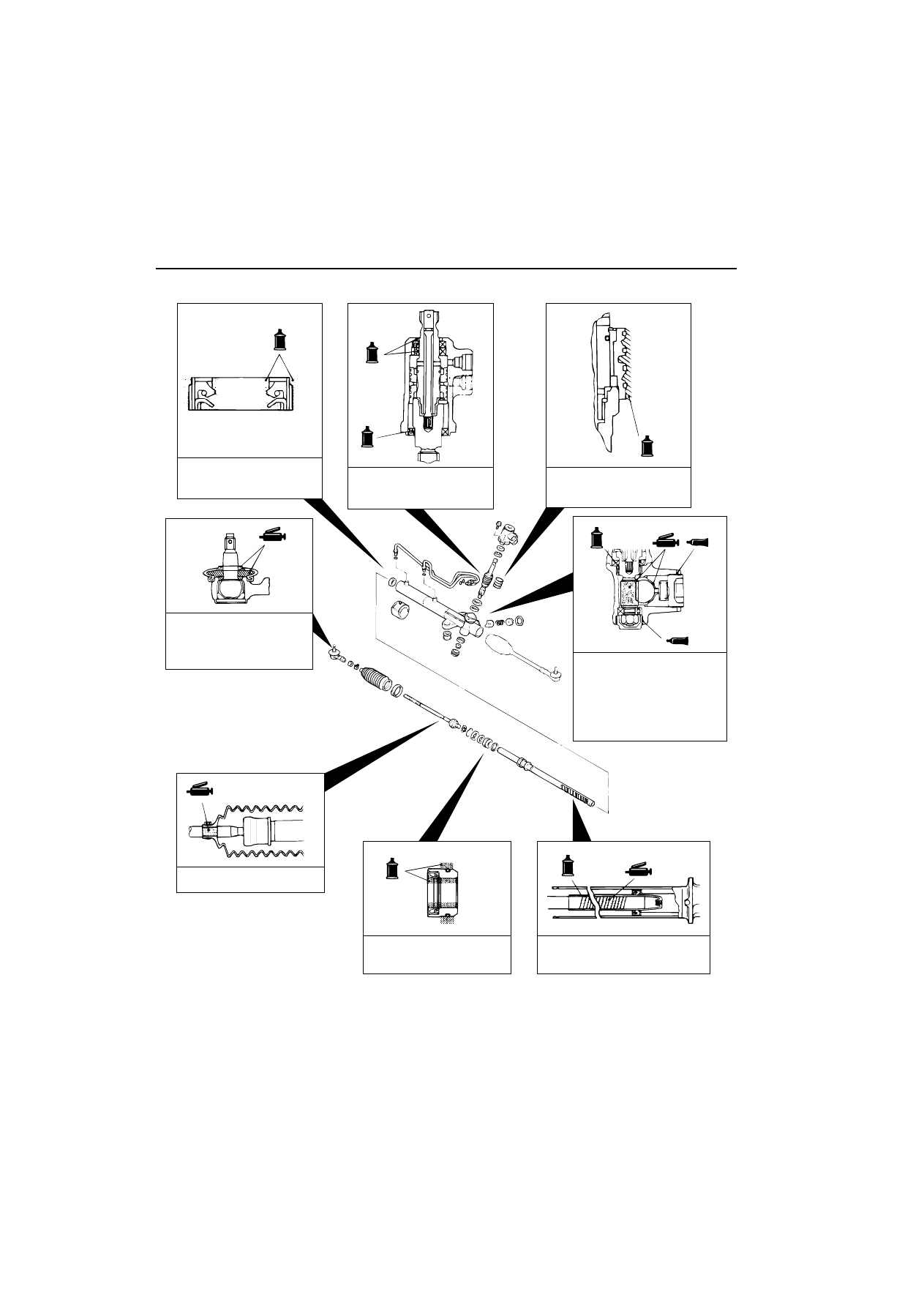

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING

37-23

LUBRICATION AND SEALING POINTS

AC200119 AC

Grease: Silicone grease

Fluid:

ATF DXRON III or

DEXRON II

Grease: Repair kit grease

Fluid:

ATF DXRON III or

DEXRON II

Sealant:

3M ATD Part No. 8661, 8663

or equivalent

Grease:

Multipurpose grease

SAE J310, NLGI No.2

or equivalent

Fluid:

ATF DXRON III or

DEXRON II

Fluid:

ATF DXRON III or

DEXRON II

Fluid:

ATF DXRON III or

DEXRON II

Grease: Repair kit grease

Fluid:

ATF DXRON III or DEXRON II