Mitsubishi Outlander (2003+). Manual - part 235

DRIVE SHAFT ASSEMBLY

REAR AXLE <4WD>

27B-11

REMOVAL SERVICE POINTS

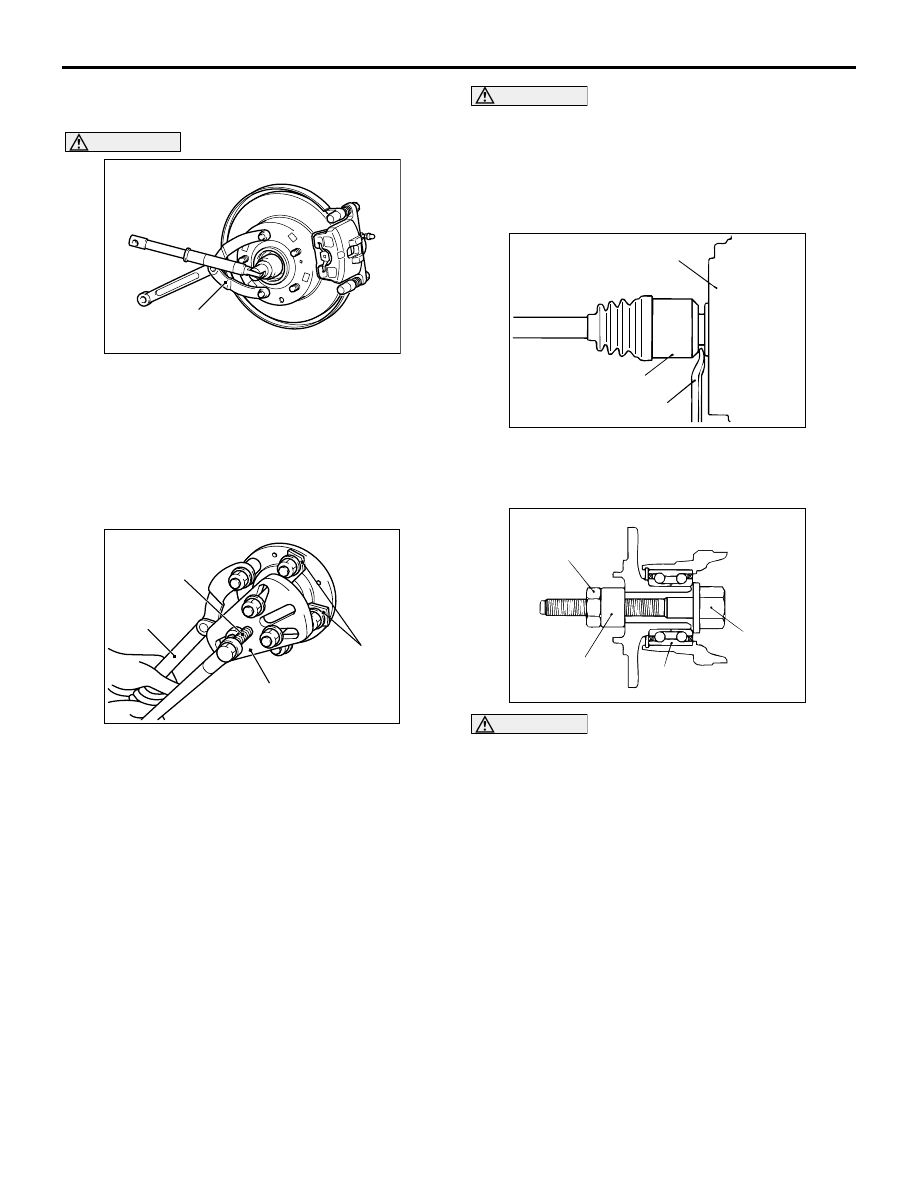

<<A>> DRIVE SHAFT NUT REMOVAL

CAUTION

Do not apply pressure to wheel bearing by the

vehicle weight to avoid possible damage to

wheel bearing before tightening drive shaft nut

fully.

Use special tool end yoke holder (MB990767) to fix

the hub and remove the drive shaft nut.

<<B>> DRIVE SHAFT REMOVAL

1. Use the following special tools to push out the

drive shaft from the hub.

•

Puller shaft (MB990242)

•

Puller bar (MB990244)

•

Puller body (MB991354)

•

End yoke holder (MB990767)

CAUTION

•

Do not pull on the drive shaft; doing so will

damage the TJ; be sure to use the pry bar.

•

When pulling the drive shaft out from the

differential carrier, be careful that the spline

part of the drive shaft does not damage the oil

seal.

2. Remove the drive shaft from the differential carrier

by using a pry bar.

CAUTION

Do not apply pressure to the wheel bearing by

the vehicle weight to avoid possible damage

when the drive shaft is removed. If, however,

vehicle weight must be applied to the bearing in

moving the vehicle, temporarily secure the wheel

bearing by using the following special tools.

•

Front hub remover and installer (MB991017)

•

Spacer (MB991000)

AC201826

AC

MB990767

AC201827

MB991354

MB990244

(MB990241)

MB990242

(MB990241)

MB990767

AC

(Three)

AC102552 AE

TJ assembly

Pry bar

Differential carrier

AC102720

MB991000

MB991017

245 ± 29 N·m

AC

Wheel bearing