Mitsubishi Montero Sport (2004+). Manual - part 304

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-629

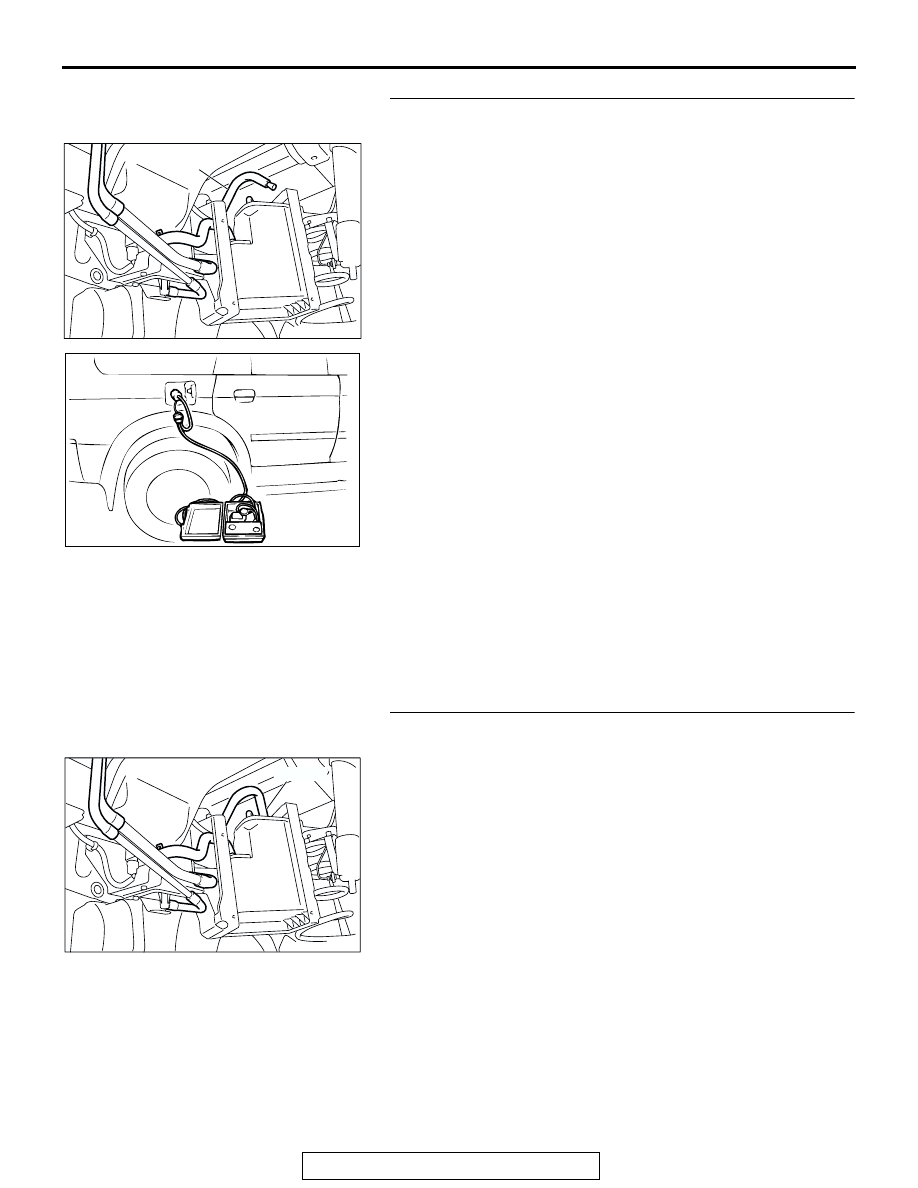

STEP 7. Pressure test the evaporative emission system

lines from hose E, L and the fuel tank.

(1) Disconnect hose E from the canister side, and plug the

hose.

(2) Remove the fuel cap.

(3) Confirm that the evaporative emission system pressure

pump (Miller number 6872A) is operating properly. Perform

the self-test as described in the manufacturer's instructions.

(4) Connect the evaporative emission system pressure pump

to the fuel filler neck.

(5) Pressure test the system to determine whether any leaks

are present.

NOTE: The "Pressure test" in this procedure refers to the

I/M240 Simulation Test. The eight steps of this test are

described in the manufacturer's instructions for the evapo-

rative emission system pressure pump, Miller number

6872A.

(6) After it is confirmed that pressure maintained, unplug hose

E.

(7) Disconnect the evaporative emission system pressure

pump, and reinstall the fuel cap.

(8) Connect hose E to the evaporative emission canister.

Q: Is the evaporative emission system line free of leaks?

YES : Go to Step 15 .

NO : Go to Step 8 .

STEP 8. Check vacuum for leaks in the evaporative

emission system hose E.

Perform a leakage test with a hand vacuum pump on hose E.

Q: Does the hose N hold vacuum?

YES : Go to Step 9 .

NO : Replace the damaged hose E. (Refer to GROUP 17,

Evaporative Emission Canister and Fuel Tank

Pressure Relief Valve

AC005140

HOSE E

AC

ACX01358

AC004932

HOSE E

AH