Mitsubishi Montero Sport (2004+). Manual - part 276

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-517

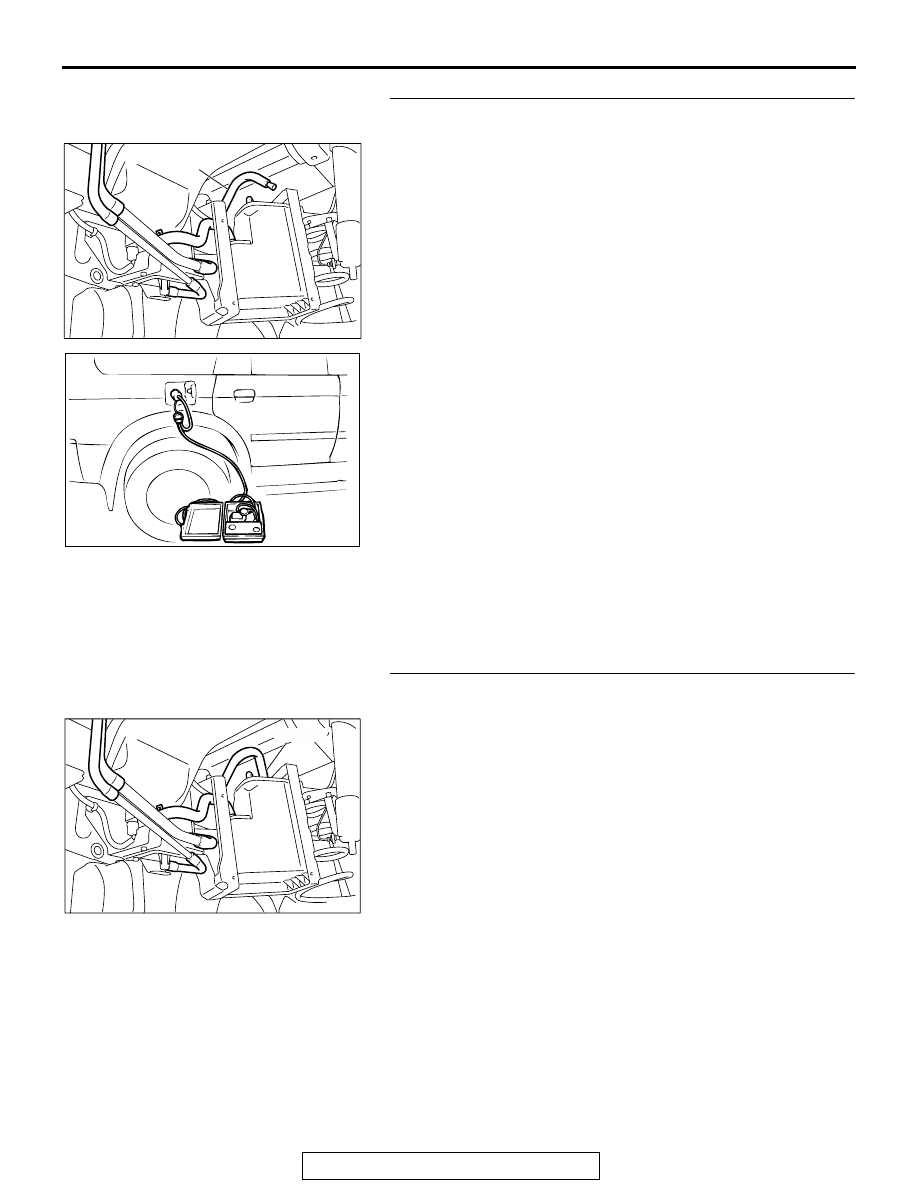

STEP 7. Pressure test the evaporative emission system

lines between hoses E to hose L and the fuel tank.

(1) Disconnect hose E from the canister side, and plug the

hose.

(2) Remove the fuel cap.

(3) Connect the evaporative emission system pressure pump

to the fuel filler neck.

(4) Apply a pressure on the evaporative emission system

pressure pump, and confirm that air is maintained.

NOTE: The "Pressure test" in this procedure refers to the

I/M240 Simulation Test. The eight steps of this test are

described in the manufacturer's instructions for the evapo-

rative emission system pressure pump, Miller number

6872A.

(5) Disconnect the evaporative emission system pressure

pump, and reinstall the fuel cap.

(6) Connect hose E to the evaporator line.

Q: Is the evaporative emission system line free of leaks?

YES : Go to Step 15 .

NO : Go to Step 8 .

STEP 8. Check for vacuum leak in evaporative emission

system hose E.

Perform a leakage test with a hand vacuum pump on hose E.

Q: Does the hose E hold vacuum?

YES : Go to Step 9 .

NO : Replace the damaged hose. Then go to Step 16 .

AC005140

HOSE E

AC

ACX01358

AC004932

HOSE E

AH