Mitsubishi Montero (2004+). Manual - part 527

COMBINATION METER ASSEMBLY AND VEHICLE SPEED SENSOR

TSB Revision

CHASSIS ELECTRICAL

54A-77

INSPECTION

M1543019501783

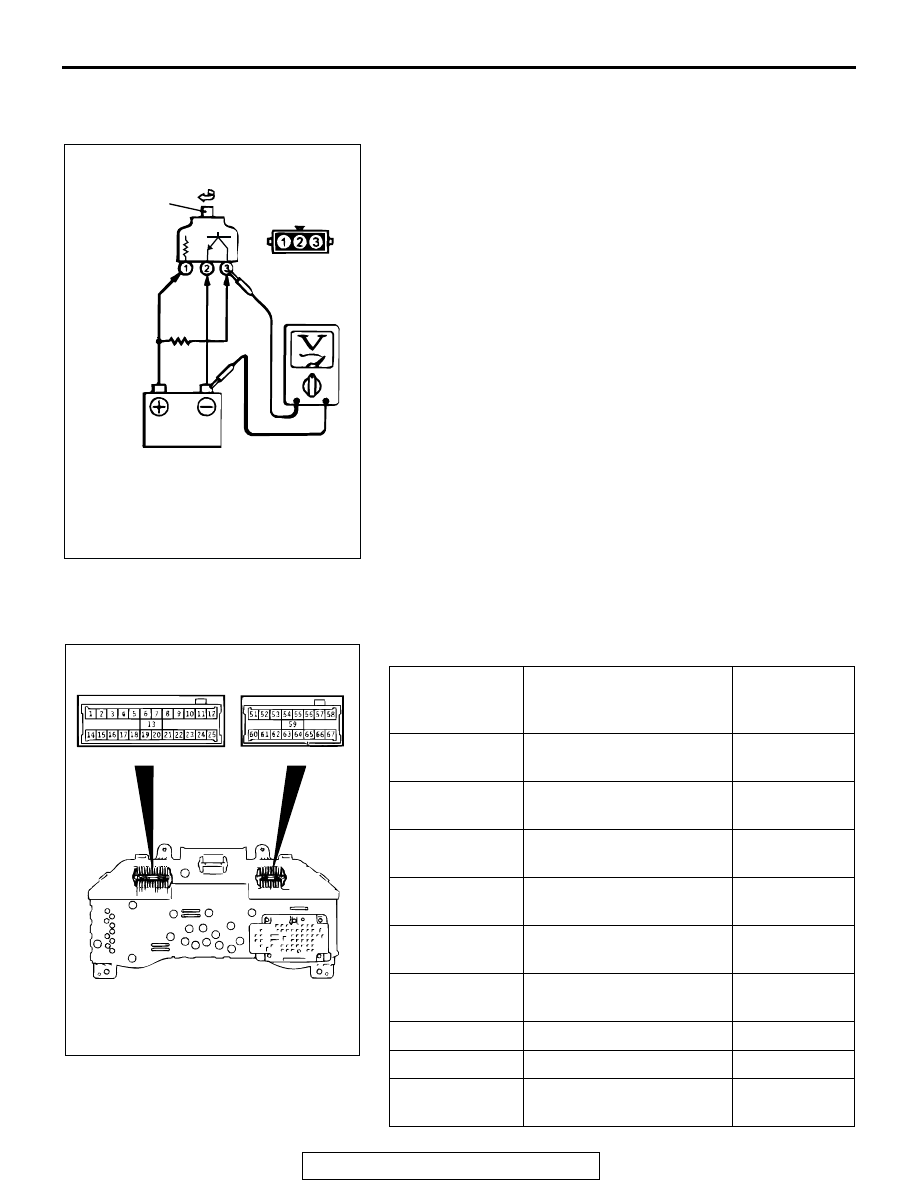

VEHICLES SPEED SENSOR CHECK

1. Remove the vehicle speed sensor and connect a 3

− 10 kilo

ohms resistor as shown in the illustration.

2. Turn the shaft of the vehicle speed sensor and check that

there is voltage between terminals 2 and 3. (1 turn = 4

pulses)

3. If within the standard value, the vehicle speed sensor is OK.

If not within the standard value, replace the vehicle speed

sensor.

COMBINATION METER INTERNAL RESISTANCE

CHECK

Measure the resistance between terminals using an ohmmeter.

AC102349AB

TURN

SHAFT

RESISTOR

3 - 10

TERMINAL NO.

TO MEASURE

RESISTANCE

TERMINAL NAME

STANDARD

VALUE

25

− 67

Battery power supply and

ground

1 M

Ω or more

11

− 67

Battery power supply and

ground

1 M

Ω or more

25

− 62

IG power supply and

ground

1 M

Ω or more

11

− 62

IG power supply and

ground

1 M

Ω or more

63

− 67

Battery power supply and

fuel gauge

1 M

Ω or more

62

− 63

IG power supply and fuel

gauge

1 M

Ω or more

25

− 63

Fuel gauge and ground

180

Ω

11

− 63

Fuel gauge and ground

180

Ω

64

− 67

Battery power supply and

water temperature gauge

1 M

Ω or more

ACX00783

D-03

D-05

AB