Mitsubishi Montero (2004+). Manual - part 466

SPECIAL TOOLS

TSB Revision

REAR AXLE

27-3

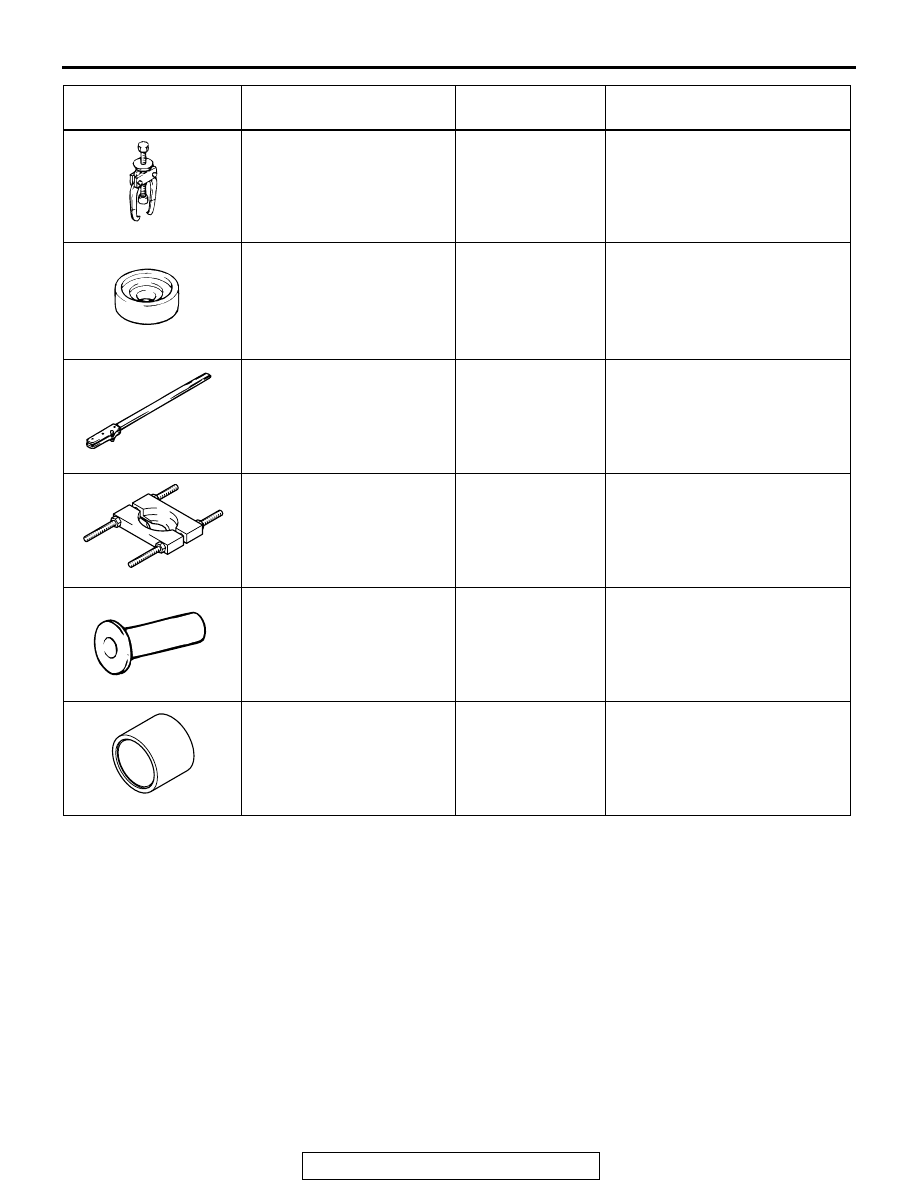

MB990810

Side bearing puller

MB990810-01

• Removal of the side bearing

inner race

• Removal of the companion

flange

MB991407

Differential rear support

arbor

−

Removal of the side bearing

inner race

MB990850

End yoke holder

−

• Removal of the self-locking

nut

• Adjustment of the drive

pinion turning torque

MD998801

Bearing remover

−

Removal of the drive pinion rear

bearing inner race

MB991168

Drive pinion oil seal installer

−

Press-fitting of the drive pinion

oil seal

MB991445

Bushing remover and

installer base

−

Press-fitting of the drive pinion

rear bearing outer race (Use

together with MB990938)

TOOL

TOOL NUMBER AND

NAME

SUPERSESSION

APPLICATION

MB990810

MB991407

MB990850

MB991168