Mitsubishi Montero (2004+). Manual - part 326

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-791

DTC SET CONDITIONS <Range/Performance problem

− relation between main and sub>

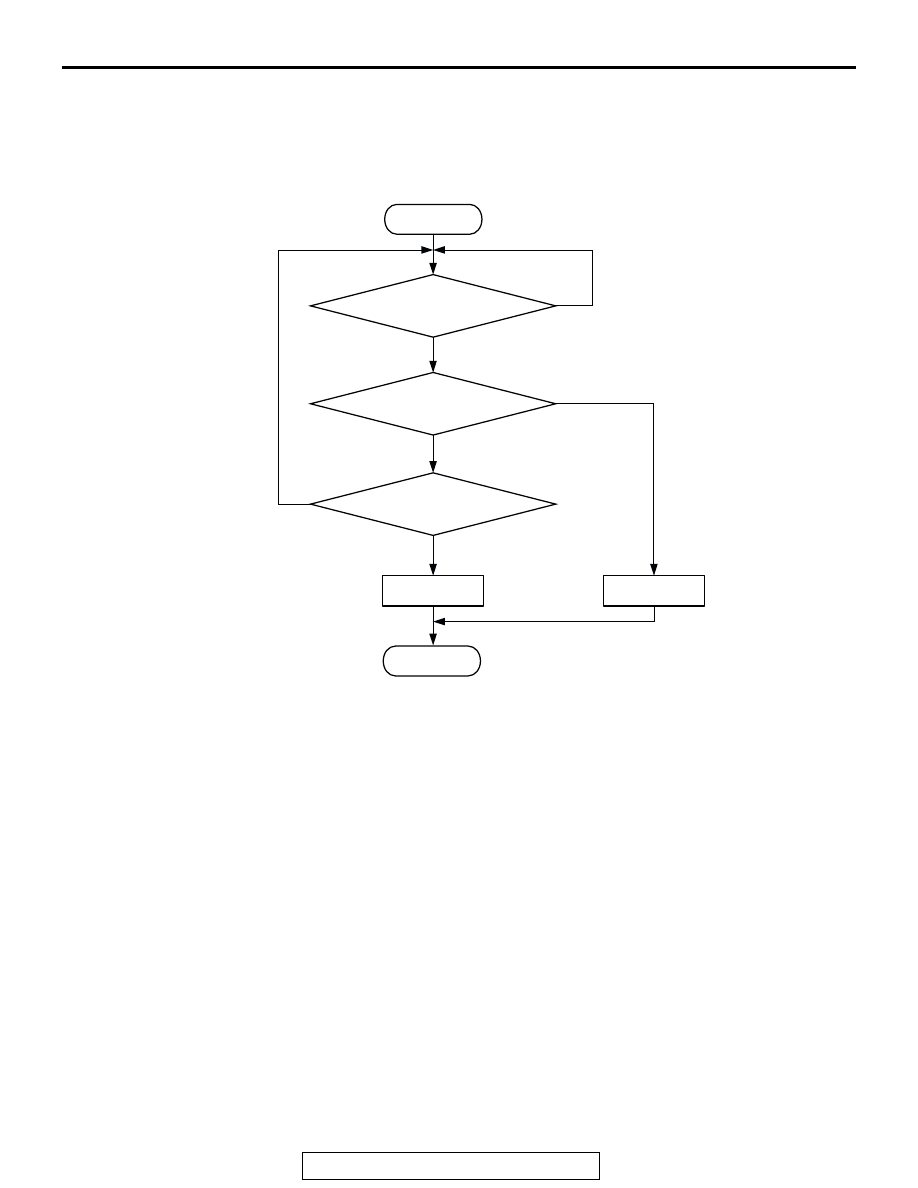

Logic Flow Chart

.

Check Condition

• Ignition switch "ON" position.

• Accelerator pedal position sensor (main) output

voltage is between 0.2 and 4.5 volts.

• Accelerator pedal position sensor (sub) output

voltage is between 0.2 and 4.5 volts.

• Change of accelerator pedal position sensor

(sub) output voltage per 25 miliseconds is lower

than 0.06 volt.

Judgement Criteria

• Voltage obtained with the formula given below is

1.0 volt or higher for 0.2 second: [accelerator

pedal position sensor (main) output voltage

−

accelerator pedal position sensor (sub) output

voltage +0.3 volt].

.

OBD-II DRIVE CYCLE PATTERN

None.

.

TROUBLESHOOTING HINTS (The most likely

causes for this code to be set are:)

• APS failed.

• Harness damage, or connector damage in APS

circuit.

• PCM failed.

DIAGNOSIS

Required Special Tools:

• MB991958: Scan Tool (MUT-III Sub Assembly)

START

END

NO

NO

YES

YES

YES

NO

MALFUNCTION

GOOD

CONTINUOUS

FAILURE FOR 0.2secs

MONITORING

CONDITIONS

AK302967

APS (MAIN) -

{APS (SUB) +0.3V}

> =1.0V