Mitsubishi Montero (2004+). Manual - part 122

PISTON AND CONNECTING ROD

TSB Revision

ENGINE OVERHAUL

11B-47

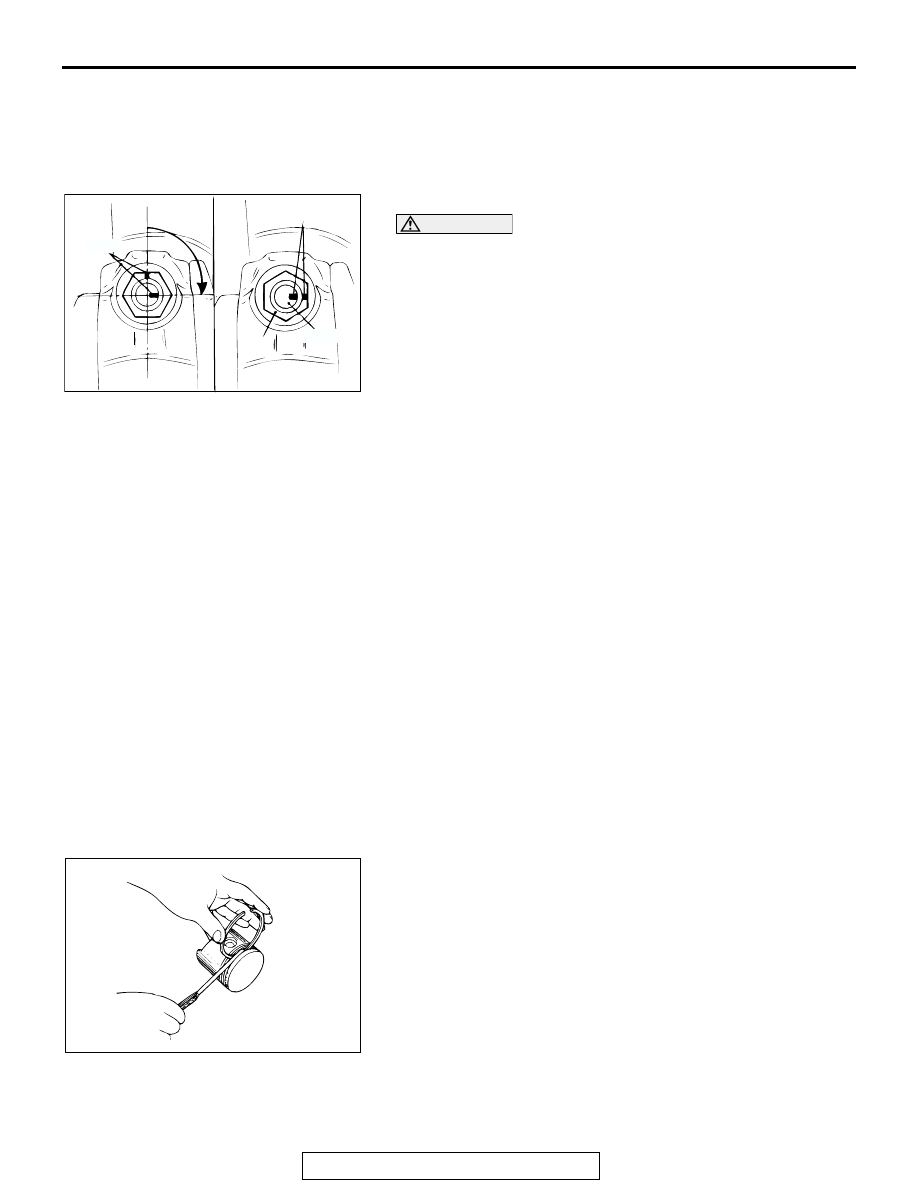

2. Before installation of each nut, apply engine oil to the

threaded portion and bearing surface of the nut.

3. Loosely tighten each nut to the bolt.

4. Then tighten the nuts alternately to a torque of 27

± 2 N⋅m

(20

± 1 ft-lb) to install the cap properly.

5. Make a paint mark on the head of each nut.

CAUTION

• If the nut is turned less than 90 degrees proper fasten-

ing performance may not be achieved. Be careful to

tighten the nut exactly 90 degrees.

• If the nut is overtightened (exceeding 94 degrees),

loosen the nut completely and then retighten it by

repeating the tightening procedure from step 3.

6. Make a paint mark on the bolt end at a position 90 degrees

to 94 degrees from the paint mark made on the nut in the

direction of tightening the nut.

7. Turn the nut another 90 to 94 degrees and make sure that

the paint marks on the nut and bolt are aligned.

INSPECTION

M1113008500439

.

PISTON

Replace the piston if scratches or seizure is evident on its sur-

faces (especially the thrust surface). Replace the piston if it is

cracked.

.

PISTON PIN

1. Insert the piston pin into the piston pin hole with a thumb.

You should feel a slight resistance. Replace the piston pin if

it can be easily inserted or there is excessive play.

2. The piston and piston pin must be replaced as an assembly.

.

PISTON RING

1. Check the piston ring for damage, excessive wear, and

breakage and replace if defects are evident. If the piston has

been replaced with a new one, the piston rings must also be

replaced with new ones.

2. Check for clearance between the piston ring and ring

groove. If the limit is exceeded, replace the ring or piston, or

both.

Standard value:

Number 1: 0.03

− 0.07 mm (0.0012 − 0.0027 inch)

Number 2: 0.02

− 0.06 mm (0.0008 − 0.0023 inch)

Limit: 0.1 mm (0.003 inch)

AKX01401AB

90˚ to 94˚

PAINT

MARKS

NUT

BOLT

PAINT

MARKS

AKX00612