Mitsubishi Montero (2004+). Manual - part 114

TIMING BELT

TSB Revision

ENGINE OVERHAUL

11B-15

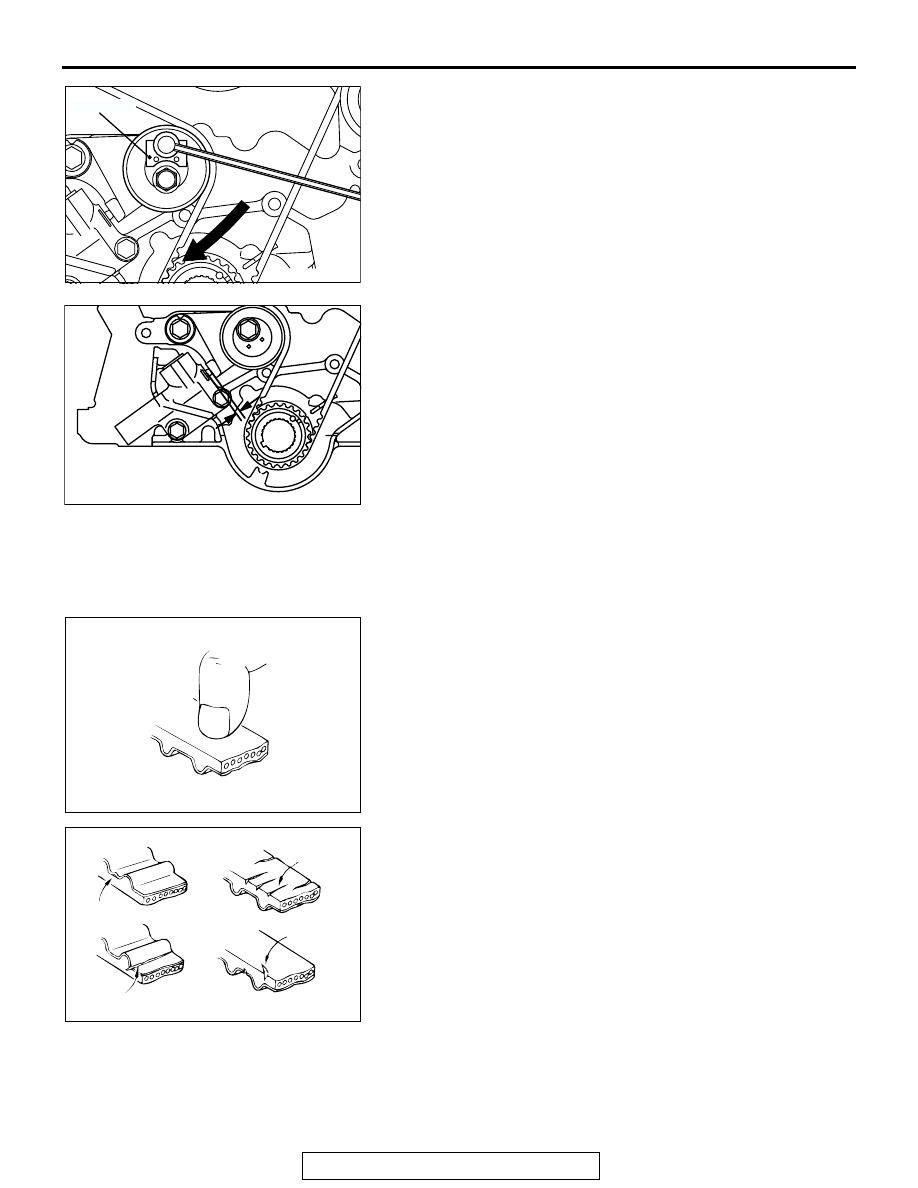

9. Mount special tool MD998767 and torque wrench on the

tensioner pulley.

10.Torque it to 4.4 N

⋅m (39 in-lb) with the torque wrench.

11.While holding the tensioner pulley in position, tighten the

center bolt to the specified torque.

Tightening torque: 48

± 6 N⋅m (35 ± 4 ft-lb)

12.Rotate the crankshaft two turns clockwise and leave it alone

for approximately five minutes.

13.Check to see whether the metal wire inserted when the

auto-tensioner was installed can be removed without any

resistance.

If the metal wire can be removed without any resistance, it

means that the belt has a proper tension. Therefore, remove

the metal wire. In this condition, check that the projection of

the rod of the auto-tensioner is within the standard value.

Standard value: 4.8

− 5.5 mm (0.19 − 0.21 inch)

14.If the metal wire offers resistance when removed, repeat the

previous steps (9) through (12) until a proper belt tension is

obtained.

INSPECTION

M1113002000276

.

TIMING BELT

Replace the belt if any of the following conditions exist.

1. Hardening of rubber backing.

Back side is glossy without resilience and leaves no indent

when pressed with fingernail.

2. Cracks on rubber back.

3. Cracks or peeling of canvas.

4. Cracks on tooth bottom.

5. Cracks on belt.

AK000024 AB

MD998767

AKX01379

AKX00749

AKX00713

CRACKS

CRACKS

PEELING

CRACKS

AB