Mitsubishi Montero (2002-2004). Manual - part 976

SYMPTOM PROCEDURES <AUTOMATIC TRANSMISSION>

TSB Revision

SYMPTOM PROCEDURES

23Ad-15

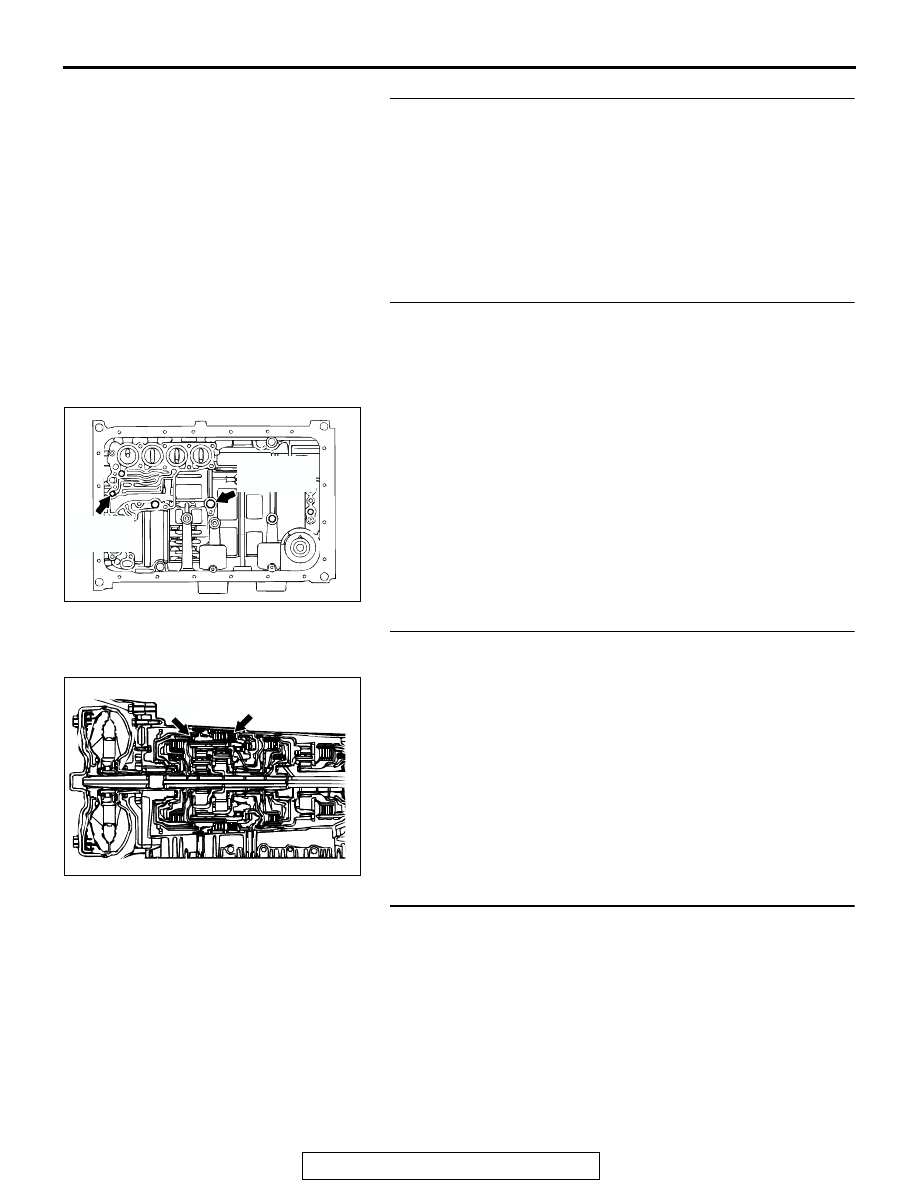

STEP 4. Check the hydraulic pressure (for low-reverse

brake).

Measure the hydraulic pressure for low-reverse brake when the

selector lever is at the "R" range. Check if the hydraulic pres-

sure is within the standard value. Refer to

, Hydraulic

Pressure Test.

Q: Is the hydraulic pressure within the standard value?

YES : Go to Step 5.

NO : Go to Step 9.

STEP 5. Check the reverse clutch system and low-reverse

brake system.

(1) Remove the valve body cover and valve body. Refer to

, Transmission and Transfer Assembly and refer

to GROUP 23B, Transmission

(2) Blow 108 kPa (15 psi) compressed air into the reverse

clutch oil orifice of the transmission case, and check if the

reverse clutch piston moves and air pressures are

maintained in that condition. Repeat for the low-reverse

brake.

Q: Are both air pressures maintained?

YES : Go to Step 6.

NO : Go to Step 9.

STEP 6. Check the reverse clutch and low-reverse brake.

(1) Remove the transmission assembly.

(2) Check the facing for seizure and the piston seal ring for

damage and interference with the retainer. Repair or

replace the faulty parts. Refer to GROUP 23B,

Transmission

, Reverse and Overdrive Clutch

. Then check for the symptom.

Q: Is the symptom eliminated?

YES : The procedure is complete.

NO : Go to Step 10.

STEP 7. Check shift shock.

Q: Does shift shock occur sometimes?

YES : Go to Step 8.

NO : Go to Step 9.

ACX02249AC

REVERSE

CLUTCH OIL

ORIFICE

LOW-REVERSE

BRAKE OIL

ORIFICE

AC204883

REVERSE

CLUTCH

LOW-REVERSE

BRAKE

AC