Mitsubishi Montero (2002-2004). Manual - part 649

TSB Revision

DIAGNOSTIC TROUBLE CODE PROCEDURES

13Ac-293

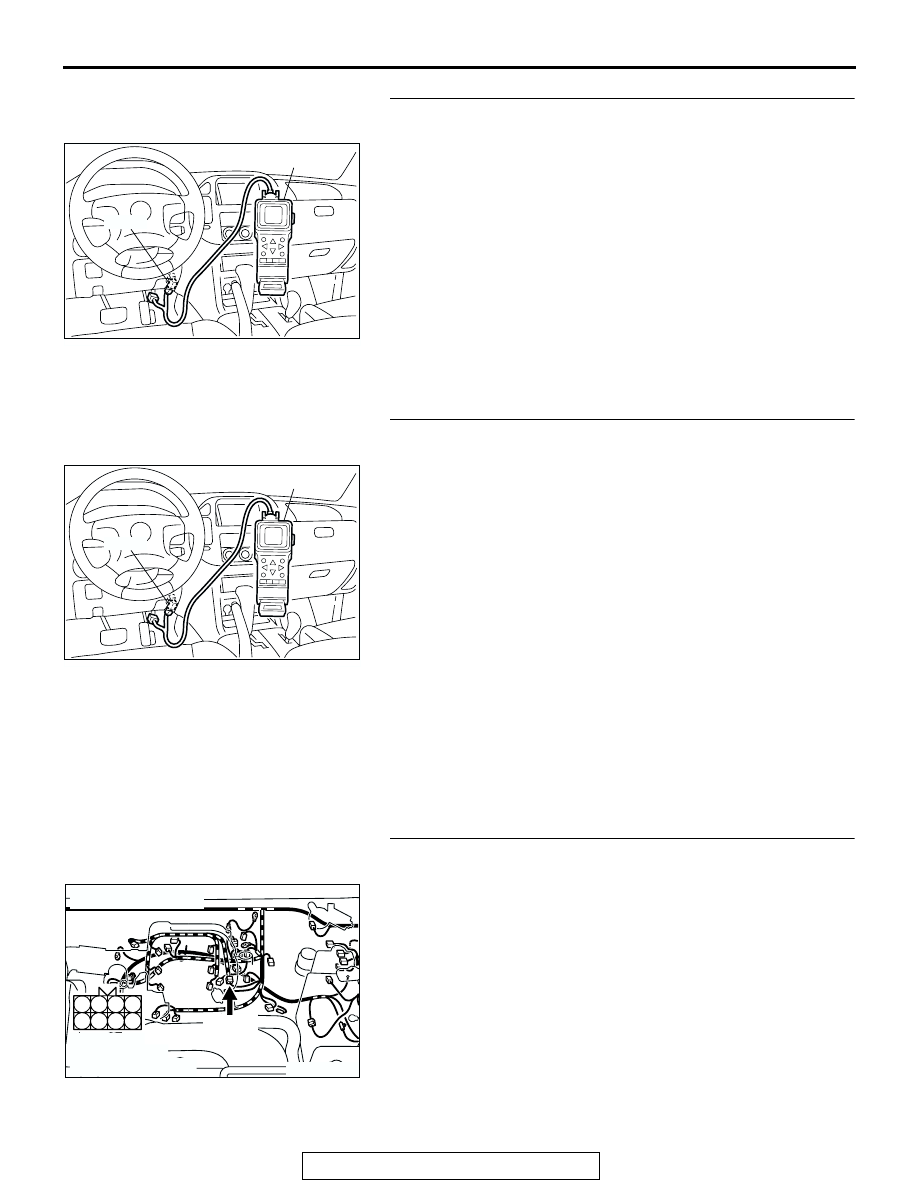

STEP 3. Using scan tool MB991502, check data list item 21:

Engine Coolant Temperature Sensor.

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool MB991502 to the data reading mode for item

21, Engine Coolant Temperature Sensor.

• The engine coolant temperature and temperature

shown with the scan tool should approximately match.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the sensor operating properly?

YES : Go to Step 4.

NO : Refer to , DTC P0116

− Engine Coolant Temperature

Circuit Range/Performance Problem

, DTC

P0117

− Engine Coolant Temperature Circuit Low

Input

, DTC P0118

− Engine Coolant

Temperature Circuit High Input

.

STEP 4. Using scan tool MB991502, check data list item 25:

Barometric Pressure Sensor.

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool MB991502 to the data reading mode for item

25, Barometric Pressure Sensor.

• When altitude is 0 m (0 foot), 101 kPa (29.8 in.Hg.).

• When altitude is 600 m (1,969 feet), 95 kPa (28.1

in.Hg.).

• When altitude is 1,200 m (3,937 feet), 88 kPa (26.0

in.Hg.).

• When altitude is 1,800 m (5,906 feet), 81 kPa. (23.9

in.Hg.)

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the sensor operating properly?

YES : Go to Step 5.

NO : Refer to , DTC P0106

− Barometric Pressure Circuit

Range/Performance Problem

, DTC

P0107

− Barometric Pressure Temperature Circuit

Low Input

, DTC P0108

− Barometric

Pressure Temperature Circuit High Input

.

STEP 5. Check harness connector B-44 at injector

intermediate connector for damage.

Q: Is the harness connector in good condition?

YES : Go to Step 6.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

. Then go to Step 10.

ACX01539

16-PIN

MB991502

AC

ACX01539

16-PIN

MB991502

AC

AK200949

3

4

7

8

1

2

5

6

B-44(B)

CONNECTOR: B-44

AB

HARNESS

CONNECTOR:

COMPONENT SIDE