Mitsubishi Montero (2002-2004). Manual - part 472

COMBINATION METERS ASSEMBLY AND VEHICLE SPEED SENSOR

TSB Revision

CHASSIS ELECTRICAL

54A-59

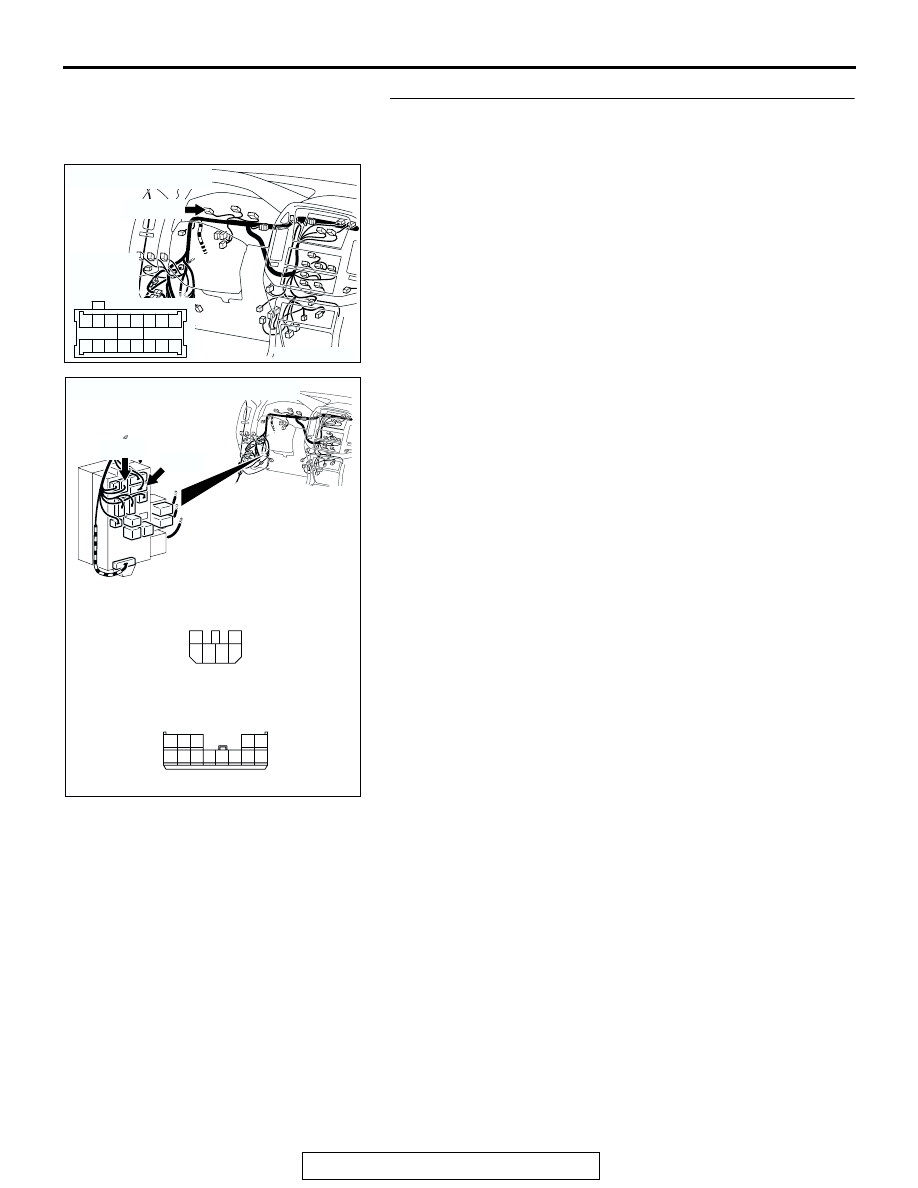

STEP 6. Check the wiring harness between combination

meter connector D-03 (terminal 62) and ignition switch

(IG1).

NOTE: Also check junction block connectors D-208 and D-210.

If junction block connector D-208 or D-210 is damaged, repair

or replace the connector as described in GROUP 00E, Harness

Connector Inspection

.

Q: Is the wiring harness between combination meter

connector D-03 (terminal 62) and ignition switch (IG1) in

good condition?

YES : There is no action to be taken.

NO : Repair the wiring harness. Check to see that all

meters operate.

AC204170

CONNECTOR : D-03

AC

D-03(GR)

HARNESS

SIDE

51

52

61 60

53

54

56

57

55

63

66 65 64

59

62

58

67

D-03(GR)

AC204191

CONNECTORS: D-208, D-210

D-208

AC

HARNESS SIDE

HARNESS SIDE

D-210

D-208

D-210

1

2

3

5

6

4

1

2

7 6

3

9

4

11

12

10

13

5

8