Mitsubishi Montero (2002-2004). Manual - part 366

INPUT SIGNAL PROCEDURES

TSB Revision

SWS INPUT SIGNAL PROCEDURES

54Bc-11

CIRCUIT OPERATION

The ETACS-ECU operates the fog lights according to

signal from the fog light switch.

.

TECHNICAL DESCRIPTION (COMMENT)

If the signal is not normal, the fog lights do not work

normally. If the signal is not normal, the fog light

switch or the ETACS-ECU may be defective.

.

TROUBLESHOOTING HINTS

• The fog light switch may be defective

• The ETACS-ECU may be defective

• The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

DIAGNOSIS

Required Special Tools:

• MB991223: Harness Set

• MB991502: Scan Tool (MUT-II)

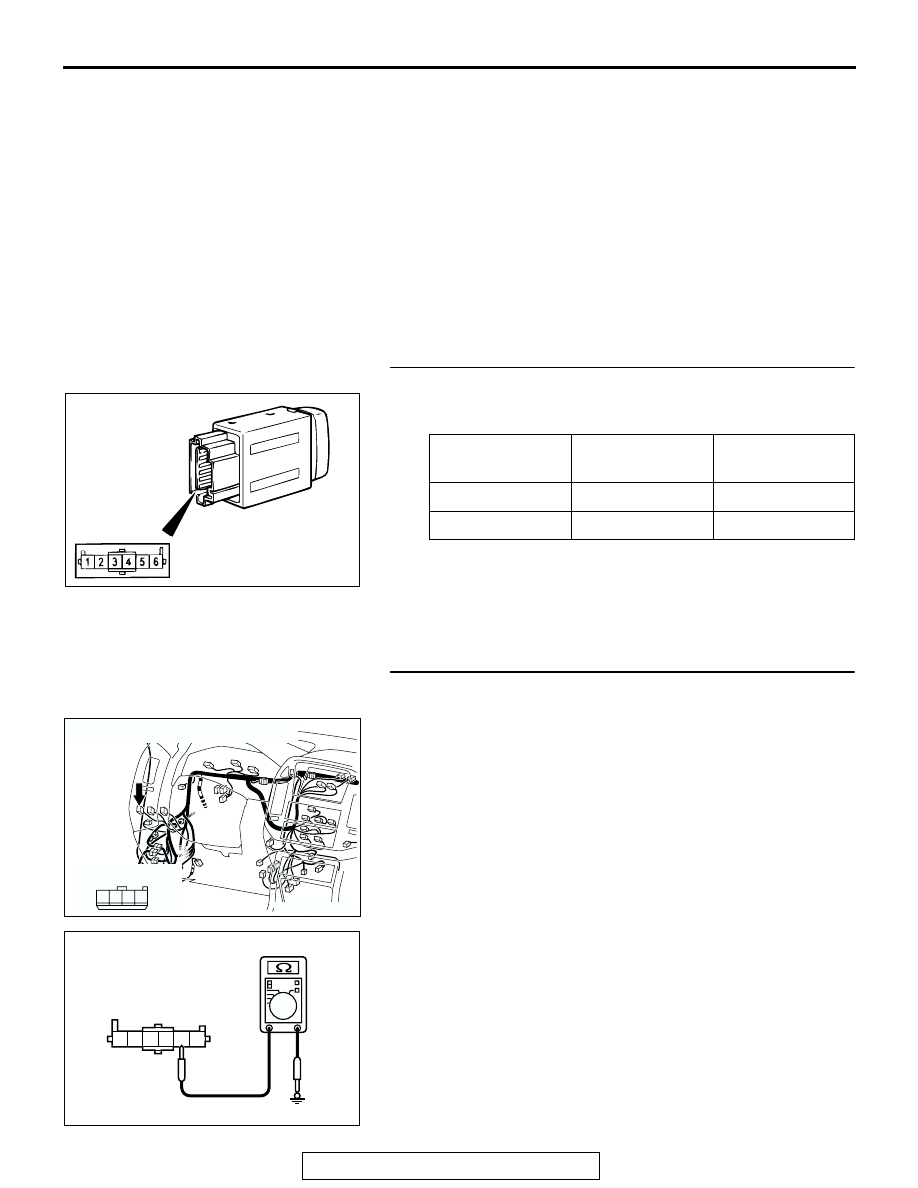

STEP 1. Check the fog light switch.

Remove the fog light switch. Then check continuity between

the switch terminals.

Q: Is the fog light switch in good condition?

YES : Go to Step 2.

NO : Repair the fog light switch. If the for light switch

operates normally, it indicates that a correct signal is

sent from the fog light switch.

STEP 2. Check the ground circuit to the fog light switch.

Test at fog light switch connector D-127.

(1) Disconnect fog light switch connector D-127 and measure

the resistance available at the wiring harness side of the

connector.

(2) Measure the resistance value between terminal 2 and

ground.

• The resistance should equal 2 ohms or less.

Q: Is the measured resistance 2 ohms or less?

YES : Go to Step 5.

NO : Go to Step 3.

SWITCH

POSITION

TESTER

CONNECTION

SPECIFIED

CONDITION

Released

1

− 2

Open circuit

Pressed

1

− 2

Less than 2 ohms

ACX00797

AC204170

CONNECTOR : D-127

HARNESS SIDE

AP

1

2

3

4

D-127

4 3 2 1

5

6

ACX01597AB

CONNECTOR D-127

(HARNESS SIDE)